Designing the world’s best reusable coffee cup

Chris Flynn explains how Bristol-based Flynn Product Design rose to the challenge with TOPL.

When our clients approached us with the brief “to create the world’s best reusable coffee cup”, naturally we stepped up. I think the unique ability of our species to solve problems is a deeply rooted part of the human experience. And it certainly drove Flynn Product Design in creating TOPL.

I’m definitely of the opinion that all products can be made better. As a product designer, I am dedicated to creating innovative products that generate emotion and improve people’s lives. How could a new reusable cup design improve the coffee drinking experience, ensuring safety from spillages and scalding from hot liquids and removing that drinking through a slot experience, which kills the aroma and partitions the sensory experience? Not to mention going for a modern classic form factor.

Gallery

Open full width

Open full width

Our client had already invested time and resources into a design that was heading completely in the wrong direction. As we were to discover, the technical challenges of TOPL were significant and the project spanned the full spectrum of Product Development to bring it to a successful conclusion.

Market research

We started from scratch by exploring what the perfect reusable coffee cup might look like. In my experience, attributing a budget for market research at the start of any project always pays dividends, and that was certainly the case with TOPL. We were able to identify brand values, perform niche scoping and establish form and format preferences.

That research led us to the creation of a minimalist ‘single use’ cup shape yet reflecting a strong lifestyle identity associated with reusable products. How do you package all that patented tech into a modern classic form?

Technical design challenges

The TOPL brief required the cup to be easy and safe to transport in a bag on the bus or tube while maintaining the temperature of the drink, re-connecting us with that ancient sensorial drinking experience and giving protection from spillages when open. Integrating these multiple features and overcoming the technical challenges of containing and transporting hot, pressurized liquids were certainly the hardest part of the project.

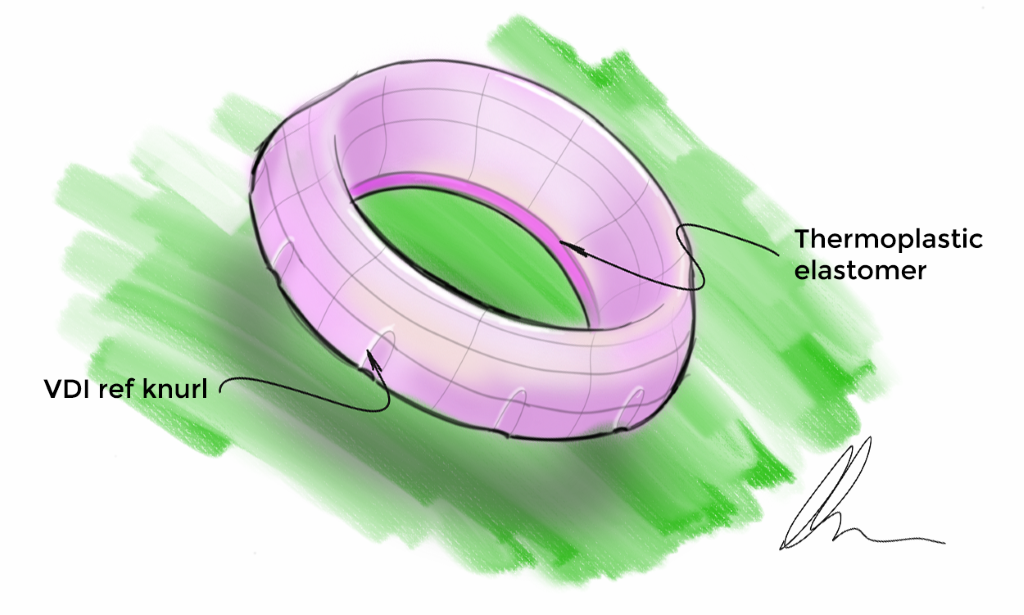

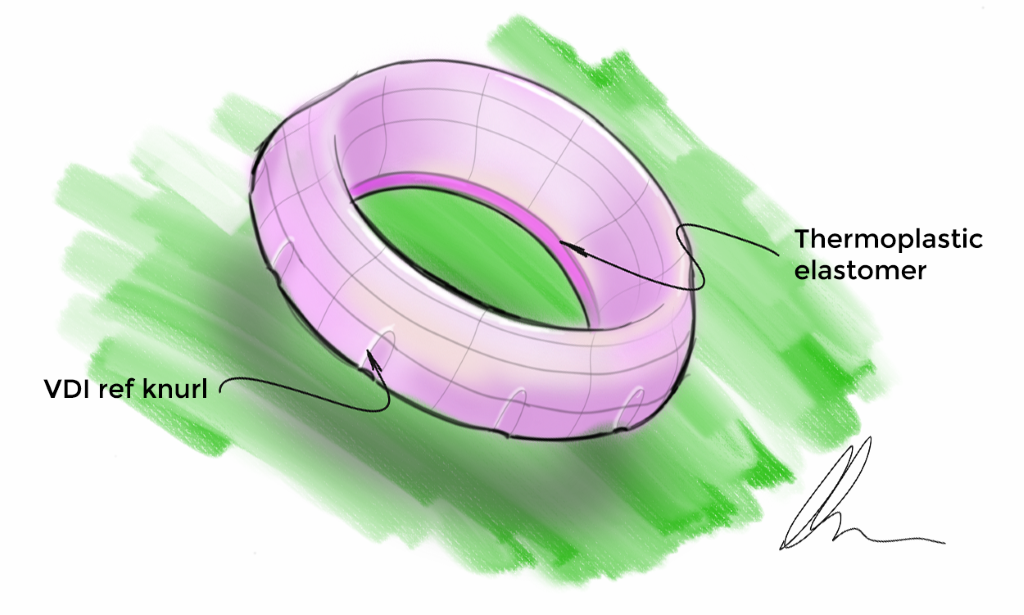

Firstly, we chose a twin wall stainless steel vacuum insulated construction to conserve the drink temperature while remaining cool to the touch. We developed a patent-pending, leak-proof rotational locking mechanism in custom food-grade materials, that keeps the contents safely inside during transport.

The top of the lid also has a 360° lip that allows users to enjoy the full aroma of the coffee from any angle, reducing the risk of scalding and without sipping through a slot. But I would say the anti-spill mechanism in the top is perhaps the biggest USP of the TOPL. Made up of a bi-stable valve lid with 3 magnets and 7 seals, it means the cup can be open on a desk or table and in the event, it is knocked over, the top immediately snaps shut.

Accidental spillages are therefore avoided, as are potential scalding or damage to Macbooks or smartphones. It is unique in that it can be open but closes automatically should it need to.

Custom materials

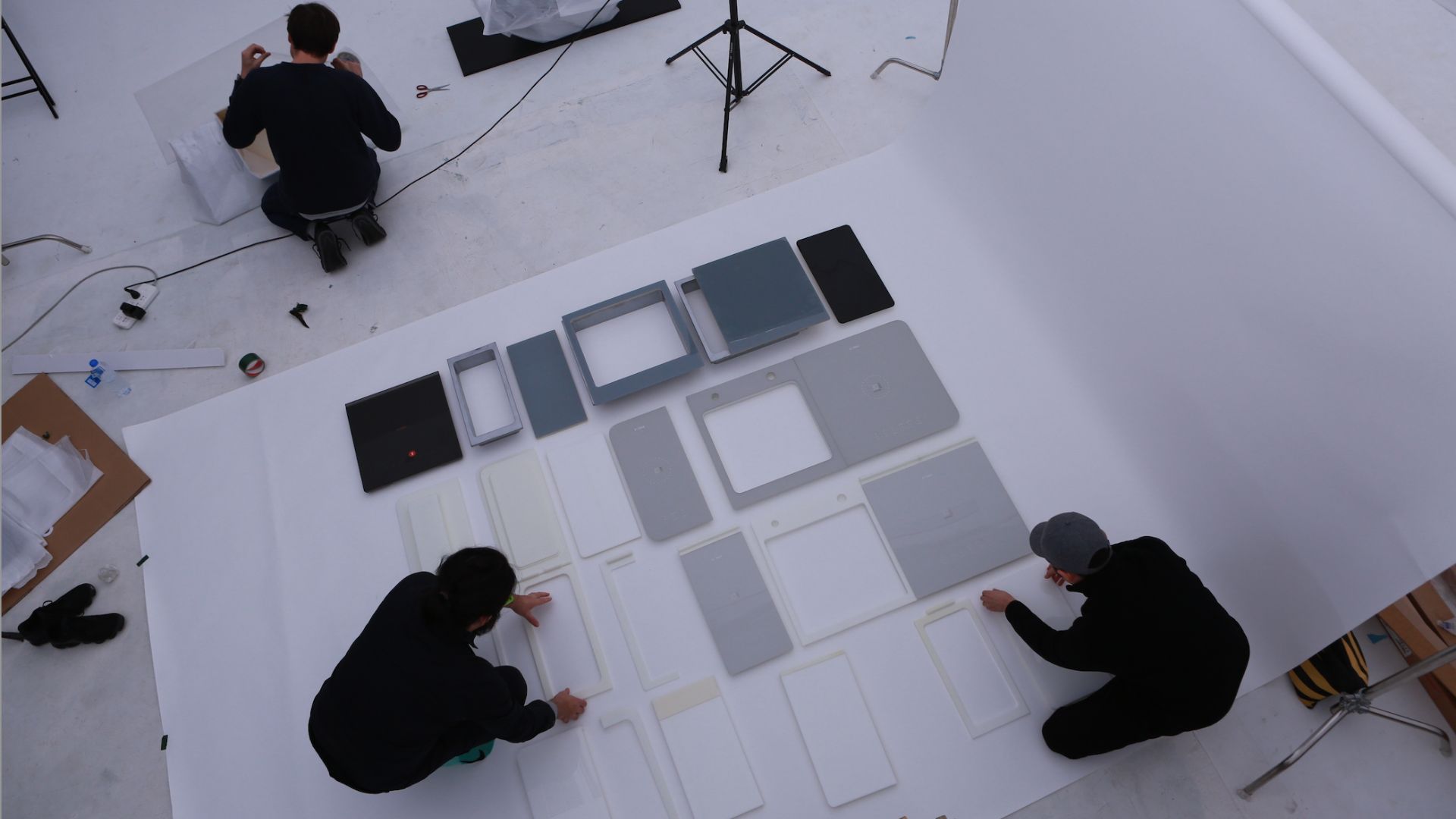

From a design perspective, we produced about 8 different prototype concepts with around 10 variations with a target temperature of 70°C and above. These included various proportions, the angle of the cup base, the profile of the lid and of course, the challenges of the lip and locking mechanism.

We knew that sourcing and testing of materials was a key element that would dictate the success of the project and so in the end we developed our own magnetic polymers.

We first looked at 3D printing and vacuum casting but eventually worked with a Dutch company that helped us create a food-grade silicone magnetic polymer. And because of the technicality of the 7 seals and the manufacturing tolerances, the test phase of the TOPL cup took over 6 months and took us out on two trips to Hong Kong.

Tooling, supply chain and costings

In every project, there are numerous and somewhat less obvious stages that follow the design, prototyping and testing of a new product. As a design consultancy with over 20 years of experience, here again we were able to use our expertise in creating the manufacture drawings and in-tool engineering.

For TOPL, we developed the in-tool prototyping and T0 to T3 production tooling.

Once the production tooling stage was completed, the project focus shifted towards matching the client with an audited supply chain and establishing costs. We had a base in HK for a few weeks of supply chain workflow and in tool prototyping.

Pre-production, manufacture and launch

We used our established industry network to broker meetings and negotiate the arrangements that led to the manufacture of the final product which was launched in 2020.

Overall, the project included rounds of market research as well as brand a product identity phases. Over the span of the project we had a few working titles and the name TOPL came through from the client towards the end. It was very much a collaboration and we are pleased to say our clients were firing on all cylinders to take TOPL to market.

TOPL – more than the sum of its parts

Since its launch last year, the TOPL design has successfully gained commercial traction and critical acclaim, from the likes of the Guardian Newspaper through to the GQ Awards, which is the ‘icing on the cake’ for the Flynn Product Design team.

We think that the classic form and better, safer and more convenient on-the-go coffee drinking experience of TOPL prove that things can always be made better. Even the humble cup that’s been around for thousands of years can be re-invented.

A key driver for us was the issue of single-use and combating those billions of land-filled paper cups. When you hit Starbucks it is a no-brainer to use a TOPL which at scale can have a positive global impact. At Flynn we refer to our philosophy as HUMAN: Our vision is to make things the best they can be and to connect humans and objects on a fundamental level – simple yet complex, functional yet emotional. I think we have achieved that with TOPL.

Article written by Flynn Product Design