Crafting a greener future – the journey of sustainable transformation in design

Operating under the “From Yellow to Green” mission, Cristina Rubinetterie has woven sustainable practices into its manufacturing processes, product development, and market communication.

By embracing resource conservation, waste management, energy efficiency, and sustainable materials, Cristina Rubinetterie exemplifies how environmental responsibility can go hand in hand with top-tier quality and innovation. Daniele Mazzon, Managing Director of the company, offers a look into the motivations behind their eco-friendly initiatives, the pivotal role of technology in minimizing environmental impact, and the way these values are embedded into every design and shared with customers.

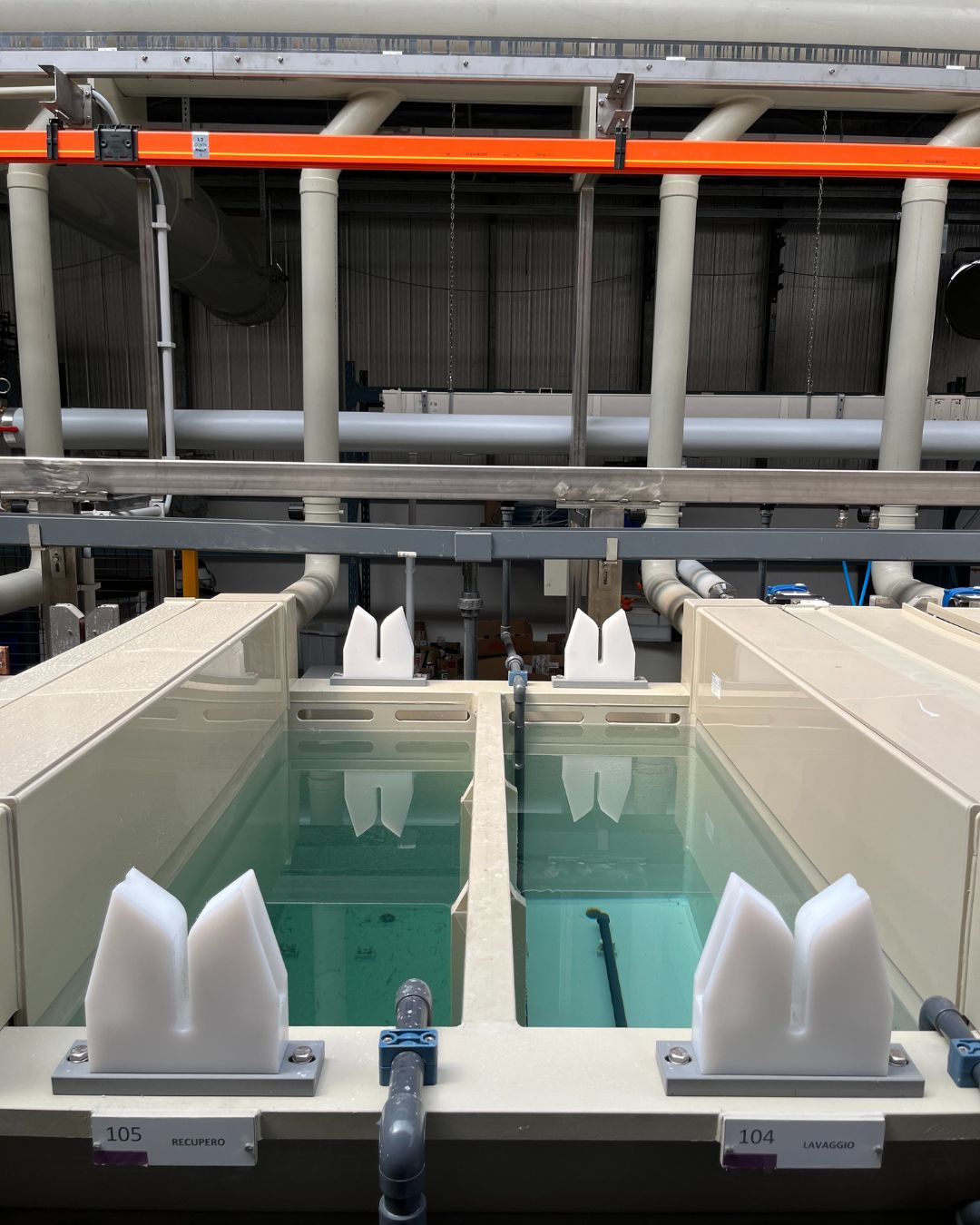

During our recent visit to their facility, we had the chance to see their new galvanic process area—a clear testament to their dedication to refining production techniques. This space emphasizes the critical role of ongoing process improvements in industrial manufacturing, where even minor reductions in waste and environmental impact can have profound, large-scale benefits.

How does Cristina Rubinetterie define “sustainability,” and what areas do their current and future initiatives focus on?

Cristina Rubinetterie:

“At Cristina Rubinetterie, sustainability is integral to our identity, guiding both our operational strategies and environmental commitments as part of our “From Yellow to Green” mission. This approach permeates various aspects of our operations, from resource conservation to sustainable materials. For instance, in our new galvanic plant, we’ve incorporated a cutting-edge water recycling system that reduces water consumption to below 1,000 liters per hour, a significant decrease compared to the industry standard. Our dedication to resource conservation is evident in this achievement, as we strive to operate more efficiently while protecting our natural resources.

Our commitment extends to waste management and a circular economy, where we actively seek partnerships to repurpose materials and minimize waste. One such collaboration with iMilani transforms plastic crates into reusable resources, demonstrating our goal to close the loop on materials. Additionally, our mechanical workshop prioritizes the complete recycling of brass, ensuring that all production waste re-enters our manufacturing process rather than going to waste. Energy efficiency is another core area, particularly in our galvanic plant. We’ve introduced advanced systems, such as automatic lids, which have reduced energy dispersion by close to 30%, a step forward in decreasing our energy footprint.

Finally, we’re embracing sustainable materials by transitioning to recycled and recyclable options for our exhibition displays and introducing trivalent chromium treatments as a safer alternative. Through these initiatives, Cristina Rubinetterie remains committed to integrating sustainability into every facet of our business.”

On our recent visit, we were impressed by the extensive efforts to enhance the galvanic process. What were the key considerations behind this investment?

Cristina Rubinetterie:

“Our investment in the new galvanic facility in Gargallo represents a significant milestone in our path to sustainable manufacturing excellence. Environmental impact reduction was a primary driver behind this investment, leading us to implement an advanced water purification system that enables water reuse and achieves a remarkable reduction in water consumption compared to traditional systems. To ensure complete environmental protection, we installed a comprehensive PVC containment platform that prevents any potential contamination.

Product quality enhancement was another crucial consideration. We introduced an innovative double nickel treatment process, incorporating both semi-bright and shiny finishes, which significantly improves corrosion resistance. Our facility now has the capability to manage trivalent chromium deposition alongside traditional processes, supported by an advanced 4.0 automated system with sophisticated management software.

The well-being of our operators was equally important in our decision-making process. We integrated robotic systems for handling galvanic bars, substantially reducing operator exposure to chemical processes. A powerful air purification system further ensures a safer working environment for our team.

Operational efficiency was carefully considered in the facility’s design. The implementation of automated systems has significantly improved production efficiency, while energy-saving features, such as automatic tank lids, reduce our environmental footprint. The facility’s layout, divided into two macro areas, optimizes both the process flow and water treatment operations, demonstrating how thoughtful design can enhance both productivity and sustainability.

This comprehensive approach to upgrading our galvanic facility reflects our broader vision of combining manufacturing excellence with environmental responsibility, setting new standards in our industry for sustainable production practices.”

How does this project convey a commitment to sustainability in your market communications?

Cristina Rubinetterie:

“Our galvanic plant project serves as a vital showcase of our approach to sustainability, proving that industrial excellence and environmental responsibility can thrive together. Through this project, we convey our dedication in several impactful ways. One of the primary aspects we highlight is the measurable environmental impact of our efforts. We transparently communicate our achievements, such as drastically reducing water consumption to less than 1,000 liters per hour—a fraction of the industry’s typical 50,000-liter daily usage for similar facilities.

This significant reduction illustrates our attention to responsible resource management and our drive to set a new industry standard. We also underscore the role of technological innovation in our sustainability journey. Our galvanic plant is equipped with Industry 4.0 automated systems and advanced management software that enhance production efficiency while fostering more sustainable operations. These technological advancements are concrete expressions of our “From Yellow to Green” mission, reflecting our belief in the transformative power of innovation.

Furthermore, we make our sustainability efforts visible and tangible. At local fairs, for example, we use displays made from 100% recycled and recyclable cardboard, creating a direct link between our environmental values and our interactions with customers and stakeholders. Through these visible initiatives, we reinforce our environmental commitment and invite our community to join us in supporting a sustainable future.”

Sustainability encompasses both industrial processes and products. For the latter, which factors are most relevant to the end customer, and what level of performance do you aim to provide?

Cristina Rubinetterie:

“For our end customers, we prioritize the delivery of sustainable products that consistently uphold the highest standards of quality and performance. Central to this is our focus on product durability, achieved through our enhanced galvanic process, which includes a double nickel treatment for exceptional corrosion resistance. This innovation not only extends the lifespan of our products but also minimizes the need for frequent replacements, offering a solution that is both cost-effective and environmentally conscious.

In response to the growing demand for environmentally safe products, we are making significant strides in adopting safer alternatives, such as trivalent chromium treatments. These adjustments are made without compromising the quality of our products, ensuring that customers can rely on us for both safety and superior craftsmanship.

Resource efficiency is another key component of our sustainable product design. We engineer our products to optimize water usage, carefully balancing efficiency with performance standards that meet and often surpass customer expectations. By integrating these principles into our product development, we provide solutions that cater to our customers’ desire for sustainable, high-quality products that perform reliably.”

How do designers contribute to your green initiatives, and in what ways are they engaged in the design process for new (sustainable) products?

Cristina Rubinetterie:

“Our designers stand at the forefront of our sustainability journey, playing a pivotal role in advancing our environmental goals while maintaining the highest standards of design excellence. Their contribution begins with thoughtful material selection, where they work in close collaboration with our production team to seamlessly integrate recycled and sustainable materials into our products. This careful selection process ensures that our commitment to sustainability never comes at the expense of design aesthetics or functionality.

The concept of lifecycle consideration is deeply embedded in our design philosophy. Our designers approach each project with longevity in mind, crafting taps and fittings that not only perform excellently but also maintain their quality and aesthetic appeal throughout extended periods of use. This focus on durability inherently supports our sustainability goals by reducing the need for replacement and minimizing waste.

Innovation integration represents another crucial aspect of our designers’ contribution to sustainability. They consistently collaborate on solutions that harmoniously blend sustainable practices with modern design principles. This is evident in their work developing products that are perfectly compatible with our advanced galvanic processes, and in their creation of designs that optimize material usage while minimizing waste. Their expertise also shines through in the incorporation of water conservation features that enhance rather than compromise the user experience.

Our commitment to sustainable presentation further showcases our designers’ holistic approach to environmental responsibility. They have been instrumental in developing eco-friendly display solutions, as exemplified by our innovative use of recycled cardboard exhibitors at local fairs. These displays perfectly demonstrate how sustainability and elegant design can complement each other, creating compelling presentations that reflect our environmental values while maintaining the sophisticated aesthetic our brand is known for.

Through this comprehensive approach to design, our team continues to push the boundaries of what’s possible in sustainable product development, proving that environmental responsibility and design excellence can go hand in hand.”