econitWood™ turns timber scraps into new material resources

econitWood™ addresses pressing environmental challenges with its sustainable wood manufacturing process, transforming sawdust into innovative materials for design and interiors.

Wood, a timeless material cherished for its natural beauty and versatility, is undergoing a renaissance in modern design and construction. However, concerns about deforestation, carbon emissions, and waste generation cast a shadow over its traditional usage.

In this context, innovative solutions like the econitWood™ process emerge as beacons of hope, promising to revolutionize the way we view and utilize wood-based materials. But what exactly sets econitWood™ apart from conventional methods? How does it address the pressing challenges of sustainability and resource depletion in the wood industry? And what implications does it hold for the future of interior architecture and design?

The econitWood™ process is an innovative, environmentally friendly method for producing wood-based materials. It transforms wood residues and by-products into valuable materials, utilizing advanced technologies to ensure minimal environmental impact when developing products such as particleboard, MDF (Medium Density Fiberboard), and other engineered wood products.

econitWood™ was founded in Germany by a group of experts in various fields, including forestry, materials science, engineering, and business. Its vision vision was to create a company that could address the pressing challenges facing the wood industry, such as deforestation, waste generation, and environmental degradation, while simultaneously meeting the growing demand for sustainable materials.

The resulting material is an interior furnishing material with high sound-absorbing, thermal insulation, and fire-resistant qualities, for a potential final product that can be considered CO2 neutral. This is because the econitWood™ technology lies in its zero-waste philosophy and the efficient use of raw materials.

Unlike conventional manufacturing, which often leads to significant material wastage, econitWood™ employs wood residues and by-products from other industrial processes, such as sawdust, wood chips, and forestry waste. As a result, it maximizes the use of available wood resources, a strategy supporting a circular economy and sustainable forestry practices and reducing the need for virgin wood.

Elevating sustainability through production processes

econitWood™ also promotes sustainability in various other areas of the production process, including the use of adhesive technology, energy and water usage, and 3D printing technology. Adhesives are crucial in the production of wood-based materials, and the econitWood™ process incorporates eco-friendly solutions to this end. It employs adhesives that are environmentally benign, reducing or eliminating harmful emissions. This includes the use of bio-based adhesives or those with low formaldehyde content, which substantially improves indoor air quality.

Meanwhile, the production process is meticulously designed to minimize energy consumption, making it inherently more sustainable. Additionally, the integration of energy recovery systems captures and reuses heat generated during production, further enhancing energy efficiency and reducing overall energy needs. This not only lowers the carbon footprint but also reduces operational costs, making the process economically viable.

Discover econitWood™

econitWood™ addresses pressing environmental challenges with its sustainable wood manufacturing process.

Water is also a vital resource in industrial processes, and the econitWood™ process addresses this concern through innovative water-saving techniques and closed-loop systems. These systems are designed to significantly reduce water consumption by treating and recycling the water used during production. This approach minimizes waste and ensures that the environmental footprint remains low, aligning with broader environmental conservation efforts.

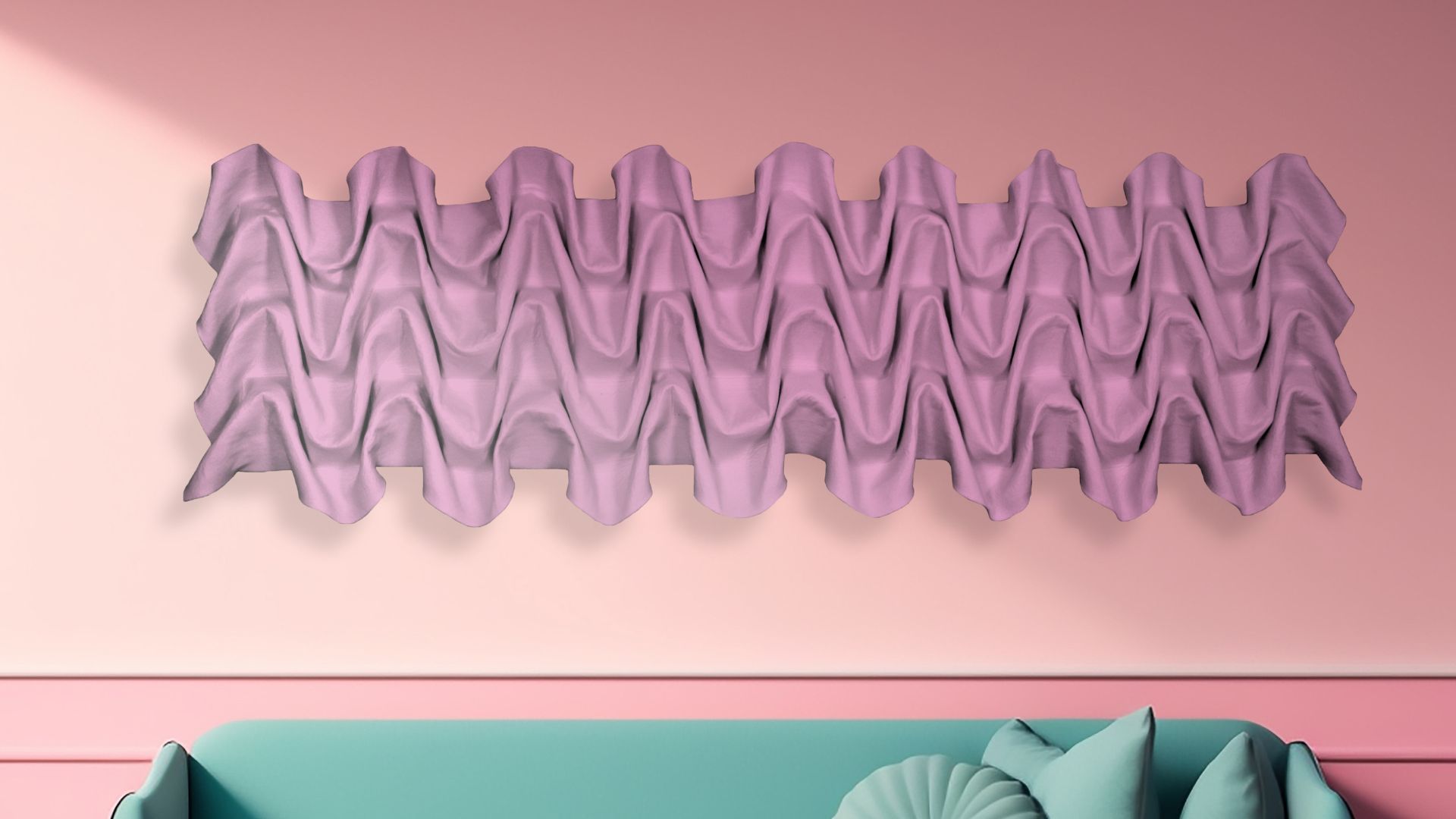

Finally, by employing 3D printing technology, the material is turned into meticulously defined geometric shapes. It represents a significant advancement in sustainable design, preserving the wood’s inherent CO2 absorption capacity and broadening its functional and aesthetic possibilities, which is demonstrative in the collaboration the brand embarked on with Italian designer Harry Thaler earlier this year.

Harry Thaler: printed nature

During Milan Design Week 2024, Thaler presented the exhibition Printed Nature in the historical setting of the nineteenth-century Villa Vagatti. As part of the exhibit, the renowned Meranese designer exhibited a new series of wooden furniture elements created through the innovative 3D printing process of econitWood™.

The exhibition took place during the Fuorisalone for the Milan Design Week within Alcova, an independent off-fair, and responded to Alcova’s vocation as a platform for designers and researchers studying the future of living and making. As such, it offered unique design pieces that reconcile, in a perfect balance, high levels of functionality, technology, and sustainability because they employed the econitWood™ production process.

The collection included inviting and sinuous seats, lamps that appear to emerge from the ground like clusters of fungi, as well as more functional stools and tables. The furniture elements were displayed against a backdrop of wood powder reminiscent of desert dunes, emphasizing the furniture creation process.

Showcasing a vast field of possibilities and the myriad experiments enabled by econitWood™ 3D printing technology, Harry Thaler embraced these opportunities with a playful attitude. He designed warm, organic shapes and boldly explored unexpected and unimaginable proportions, pushing the boundaries of creativity and innovation.

“This exhibition attempts to challenge and stretch further the boundaries of traditional architecture and design, an answer to our insatiable desire for innovation, aesthetics, and sustainable living,” explains Harry Thaler.

Besides furniture design, econitWood™ boasts various other applications. In construction, it is used to produce building materials such as particleboard and MDF for flooring, roofing, and wall panels. The process also provides materials for manufacturing furniture, cabinetry, and other interior fittings. Moreover, it can be employed in the production of sustainable packaging solutions, offering an eco-friendly alternative to traditional packaging materials.

Shaping a sustainable future in wood manufacturing

The econitWood™ process represents a leap forward in wood-based product manufacturing, echoing global endeavors to minimize environmental harm and champion sustainable practices. Its focus on sustainability, efficiency, and top-notch quality not only sets a new standard but also charts a course towards a more eco-conscious future.

A key aspect of econitWood™ lies in its made-to-order approach. This strategy eschews the need for excess inventory, slashing the environmental footprint typically associated with mass production. By tailoring each piece to individual orders, econitWood™ maximizes resource utilization while minimizing waste, aligning seamlessly with the principles of sustainability. Moreover, this method offers customers the opportunity to engage in a more conscious consumption model, where every item serves a purpose without contributing to unnecessary stockpiles.

Craftsmanship in the econitWood™ process is a delicate balance between artistic freedom and exacting precision. Leveraging cutting-edge technology and sustainable materials, artisans are empowered to create intricate designs that push the boundaries of traditional woodworking methods. The result? Unique, bespoke pieces that not only captivate aesthetically but also embody the ethos of environmental stewardship.

In conclusion, econitWood™’s commitment to quality, efficiency, and eco-friendliness not only showcases a better way of manufacturing but also underscores a broader shift towards responsible consumption. As the demand for sustainable products continues to grow, econitWood™’s brand and material position it at the forefront of this movement, offering a glimpse into a future where craftsmanship and sustainability intertwine seamlessly.

econitWood™ redefines material innovation by repurposing wood leftovers from sawmills and timber harvesting for interior architecture.