Creating a more sustainable furniture sector with European program FURN360

FURN360 provides training curriculums for designers, brands and professionals to facilitate the implementation of circular economies in the furniture industry

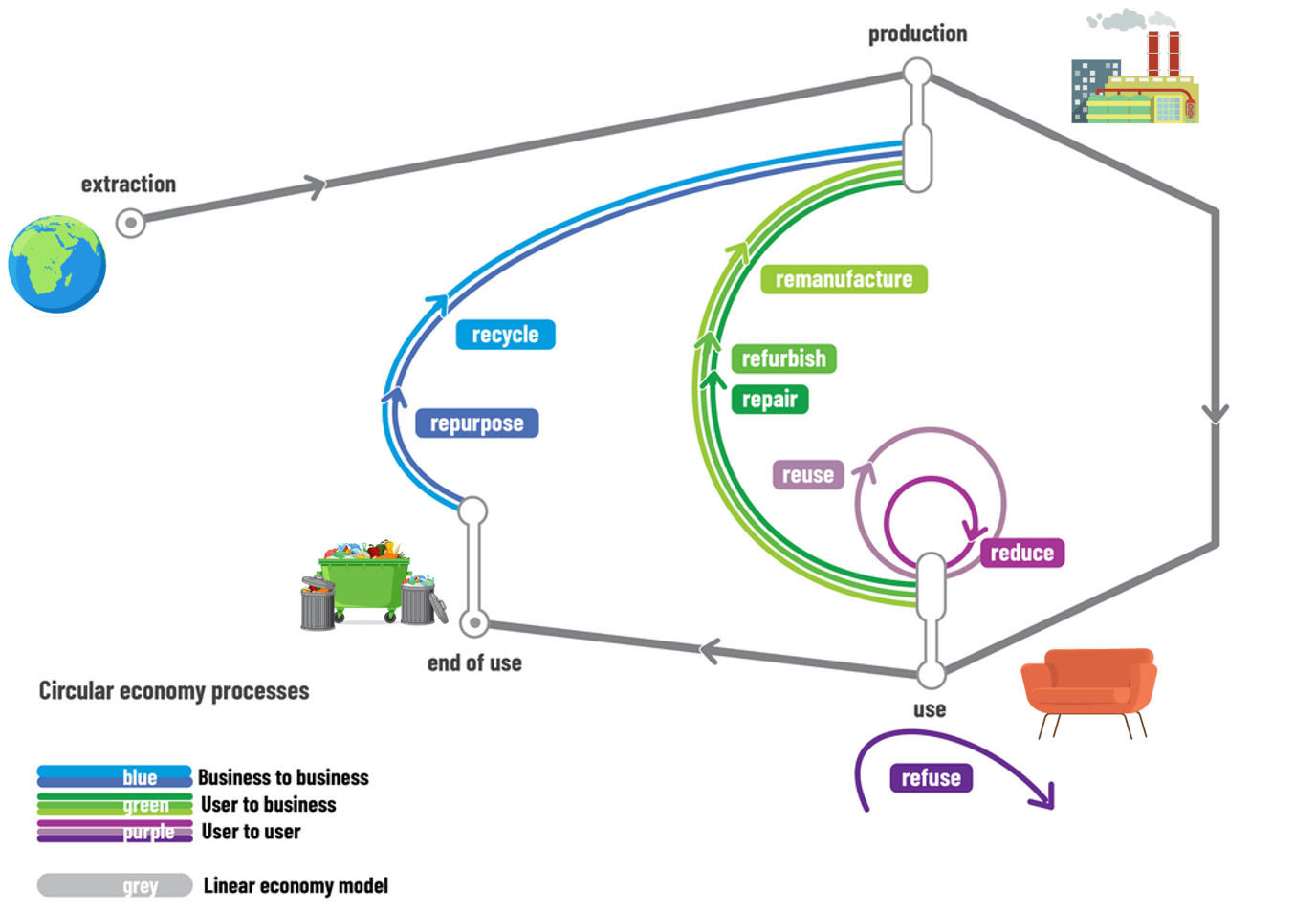

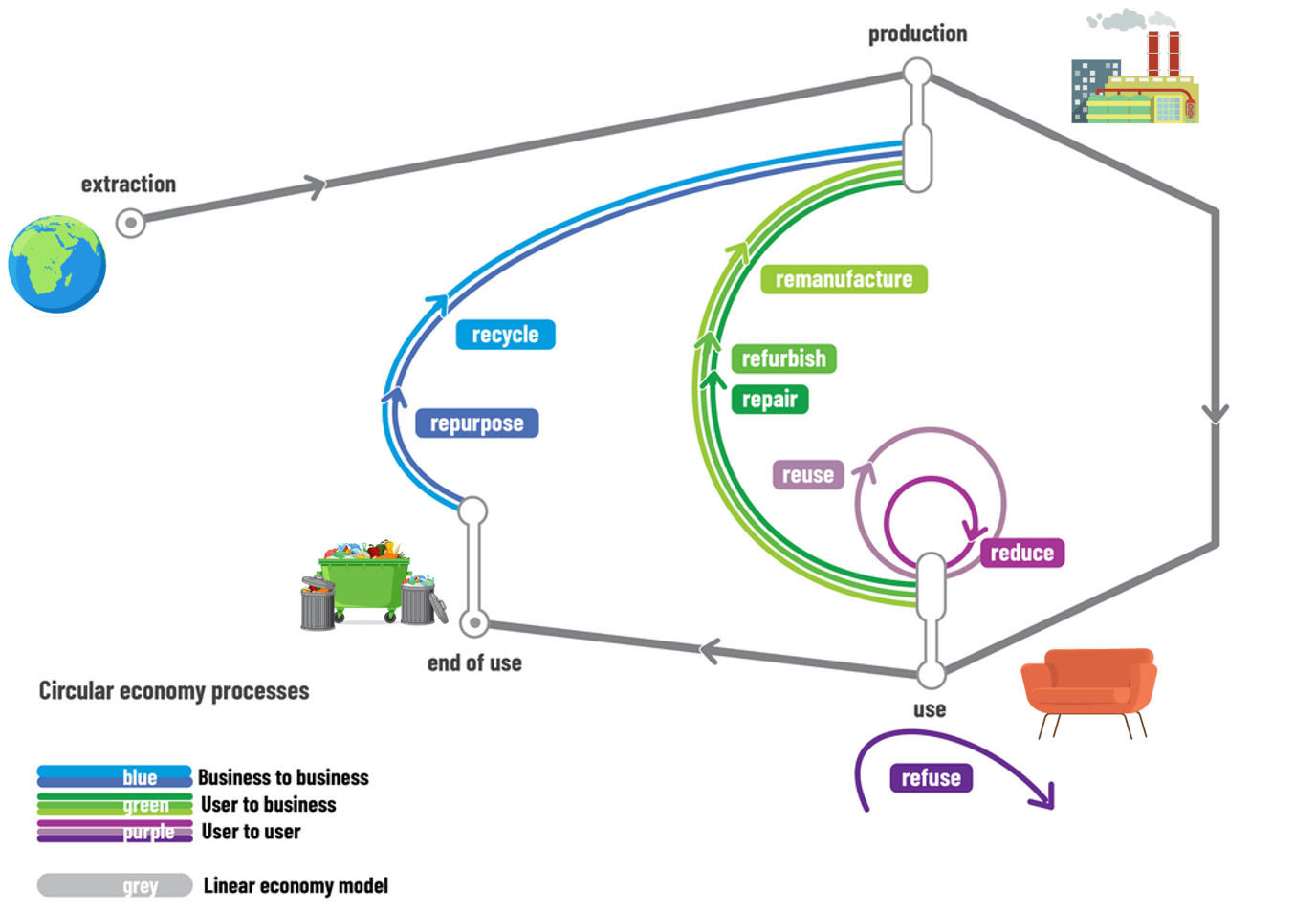

Created as a result of a long search for a sustainable furniture sector, FURN360 is a European project with the goal of developing a training curriculum to facilitate the implementation of circular business models across the furniture industry.

It is through this training curriculum and learning content that FURN360 opens the door to anyone interested in transitioning from a linear model to a circular one and gives them all the tools and strategies to achieve it.

Curious to know more, DesignWanted interviewed Juan José Ortega Gras, FURN360 Dissemination Manager and Project Manager at CETEM, to find out more about their training and why it is so important to implement a circular economy in the furniture industry.

Gallery

Open full width

Open full width

How did the journey for FURN360 begin?

Juan José Ortega Gras:

“The project idea was launched at the beginning of 2017, but it comes out as a result of a long journey for a sustainable furniture sector. The FURN360 project was born at CETEM, where we constantly monitor market trends and sustainability is a hot topic for many years.

We started firstly with some project to introduce ecodesign concept among the industry, we continued looking for new materials while fostering the implementation of green certifications, as FSC or European label, and in 2017, we consider necessary push and support companies for a circular transition. In this journey we were not alone, we did it with the involvement of our close companies and other stakeholders from around Europe.”

Why is sustainability in the furniture industry so important?

Juan José Ortega Gras:

“Nowadays sustainability is important in all sectors, as a guarantee of efficiency and responsibility, but in a traditional industry as furniture one is still more important. Sustainability is an opportunity to differentiate yourself from your competitors through design and materials while implementing green practices that boost, at the same time, the efficiency of our manufacturing processes. Therefore, sustainability is also a way to have a competitive advantage and get a clear market positioning.”

FURN 360 provides circular business training for the furniture and woodworking sectors, what are the most difficult steps in establishing a circular economy in the furniture industry?

Juan José Ortega Gras:

“In the framework of FURN360, it has been done a complete analysis on the barriers for a circular transition in the furniture industry that could be summarized in the consumer’s poor information, high cost of repair and refurbishment, difficulties to collect furniture waste, the fragmented sector, and the ageing workforce.

Anyway, to introduce circular practices in a company it is necessary to face the traditional thinking system of the company, involving all the company agents, from the CEO to the newest worker, and make them understand the benefits of this transition and not to impose changes. So, the shift of thinking and methodology systems are the key steps to establish a circular economy.”

FURN 360 aims at developing a training curriculum to facilitate the implementation of circular business models in the furniture sector, who is able to enrol in the FURN360 training?

Juan José Ortega Gras:

“The FURN360 training is open and available for anyone interested in introducing changes in its furniture company towards a circular model and also for those who are thinking to launch a new company. Thus, CEOs, marketing managers, designers, production managers, workers, current students, etc. are invited to enroll in FURN360 training. All the workers in a furniture company will learn something new to implement in their job position.”

With the FURN360 training available, along with different programs and institutions that support sustainability in the furniture sector, many furniture companies still have not implemented sustainable practices: do they have an excuse?

Juan José Ortega Gras:

“No, clearly no, there is no excuse to not join the circular transition. As I said before this is due to the most important barrier, a shift in the way of thinking and doing things in small companies, most of them continue the same methodology for generations.

But now, it is necessary to break it and start to implement changes toward a circular model. We are not speaking about a great revolution within a company, this is important, we are speaking about implementing step-by-step slight changes to be more sustainable, with a wide final objective of circularity. The first step is to analyze our manufacturing processes, from the design of a product to its sale, and identify where changes could be implemented to be more efficient and sustainable.

I’m going to add a real example of a furniture company. They were making one model of table, nice and robust, packed in one single piece. They realized that with dissemble pieces they could reduce packaging material, while at the same time doing a more efficient stock and transport. Clever! So, let’s do it, there are no excuses!”

In your opinion, how big is the role of the designer in the product system for a sustainable object?

Juan José Ortega Gras:

“Design is the key process to getting a good product, so without a sustainable, green or circular design (whatever you prefer to call it) is impossible to obtain a sustainable object. All the sustainable furniture products that you see on the market have been started with a design process.

Designers have a key role not only to introduce eco-design practices or look for new materials but also changes in the manufacturing process. Designers have to check the possibilities for them in the designed product. Thus, we can consider that a circular industry without designers’ implication is impossible.”

What would you advise to young designers who are looking to find a place in the future industry of furniture?

Juan José Ortega Gras:

“To be brave in new designs and look always for a sustainable and efficient product. I am sure that young designers have the right skills in design, but my advice is to look beyond and investigate materials, sustainable practices, and also, something very important nowadays, the great possibilities that new technologies could bring to their designs.

I’m thinking in 3D printing, simulation, augmented reality, IoT, etc., and I refer not only to how these technologies could be implemented in the design process but also in the manufacturing process as well. This is something to take into account by designers.”

Continuing to help in the implementation of sustainable practices in the furniture industry, what can we expect next from FURN360?

Juan José Ortega Gras:

“Our experience with FURN360 was greatly satisfactory. FURN360 training had a great welcome from the furniture sector. The sector was asking for this kind of training. Now, we are disseminating it through different events, as the Spanish National Environmental Congress or this Sustainable Furniture Week.

Looking beyond, all partners of FURN360 are constantly working to support the furniture sector towards a circular and digitalized industry, and are already involved or planning to launch new initiatives.

For instance, ECORES and AMUEBLA are collaborating in a new training on circular textile design (Design4Circle project); CETEM is constantly working on R&D projects to look for new biomaterials for furniture products; or CENFIM, that participated in the SAWYER project, with the aim of identifying the necessary skills for a sustainable furniture sector.

Finally, I would like to highlight the recently approved ALLVIEW project, where four partners of FURN360 are involved (CETEM, AMUEBLA, CENFIM and KIT). ALLVIEW will develop the first European Centres of Vocational Excellence Network on the furniture and wood sector based on three pillars: digitalization, social responsibility, and, obviously, circular economy. At the beginning of next year, the project website will be ready and everyone interested could follow-up on the project progress.”