How robotic felting is repurposing discarded wool into contemporary furniture

Maureen Baumeister’s Flock project transforms Europe’s unwanted sheep wool into furniture, redefining the material design system’s possibilities.

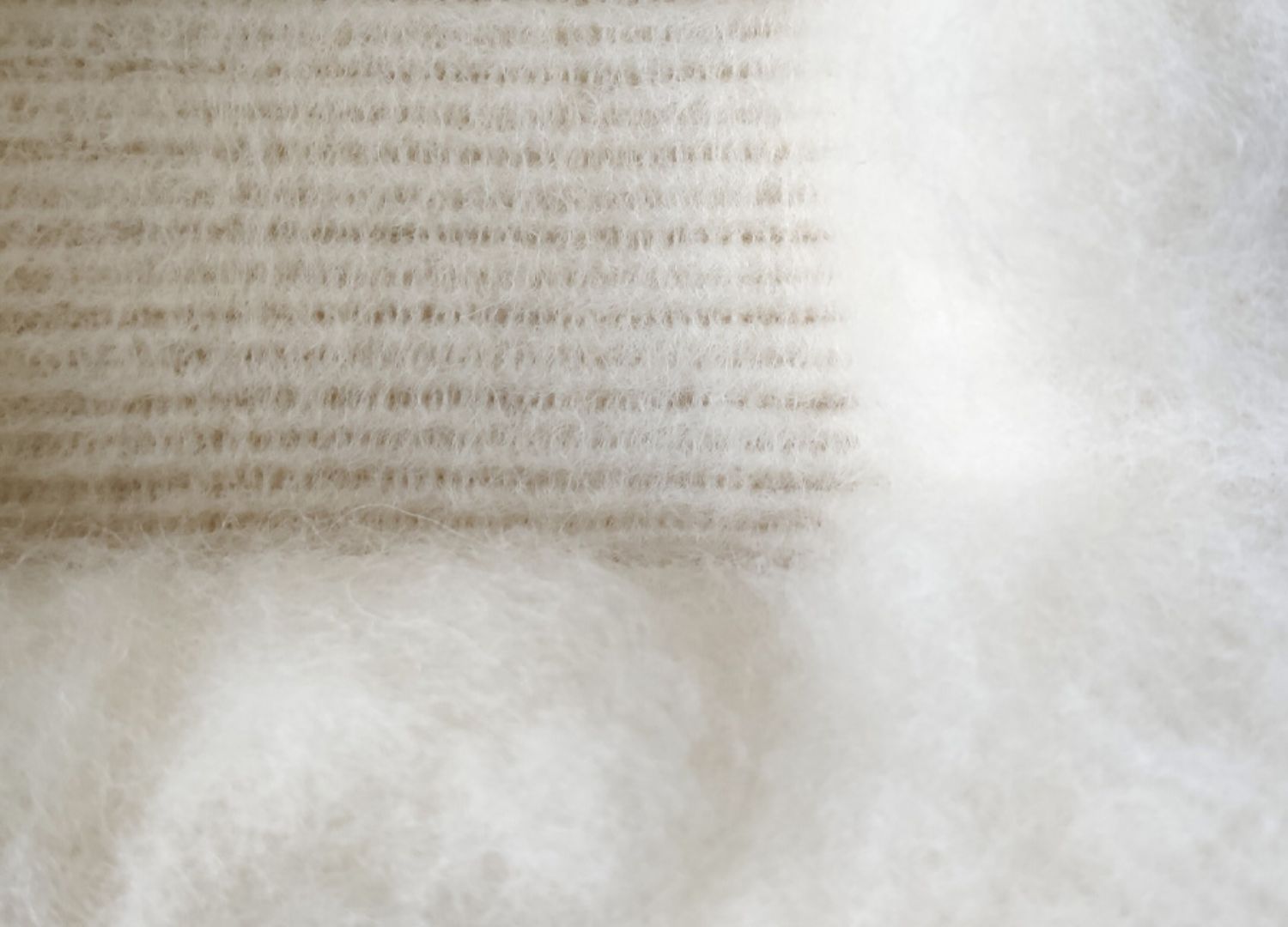

In Europe, nearly 90% of sheep wool is subject to an unhappy fate, being either burned, buried, or discarded in other ways. This is because it is of a coarser quality than the one requested by the fashion industry, leaving it a market value too low to be economically viable for shepherds. However, multidisciplinary designer Mareen Baumeister has tackled this issue head-on, finding an alternative for the future of this material. Through the Flock project, she uses waste wool and transforms it into a structural material using robotic felting.

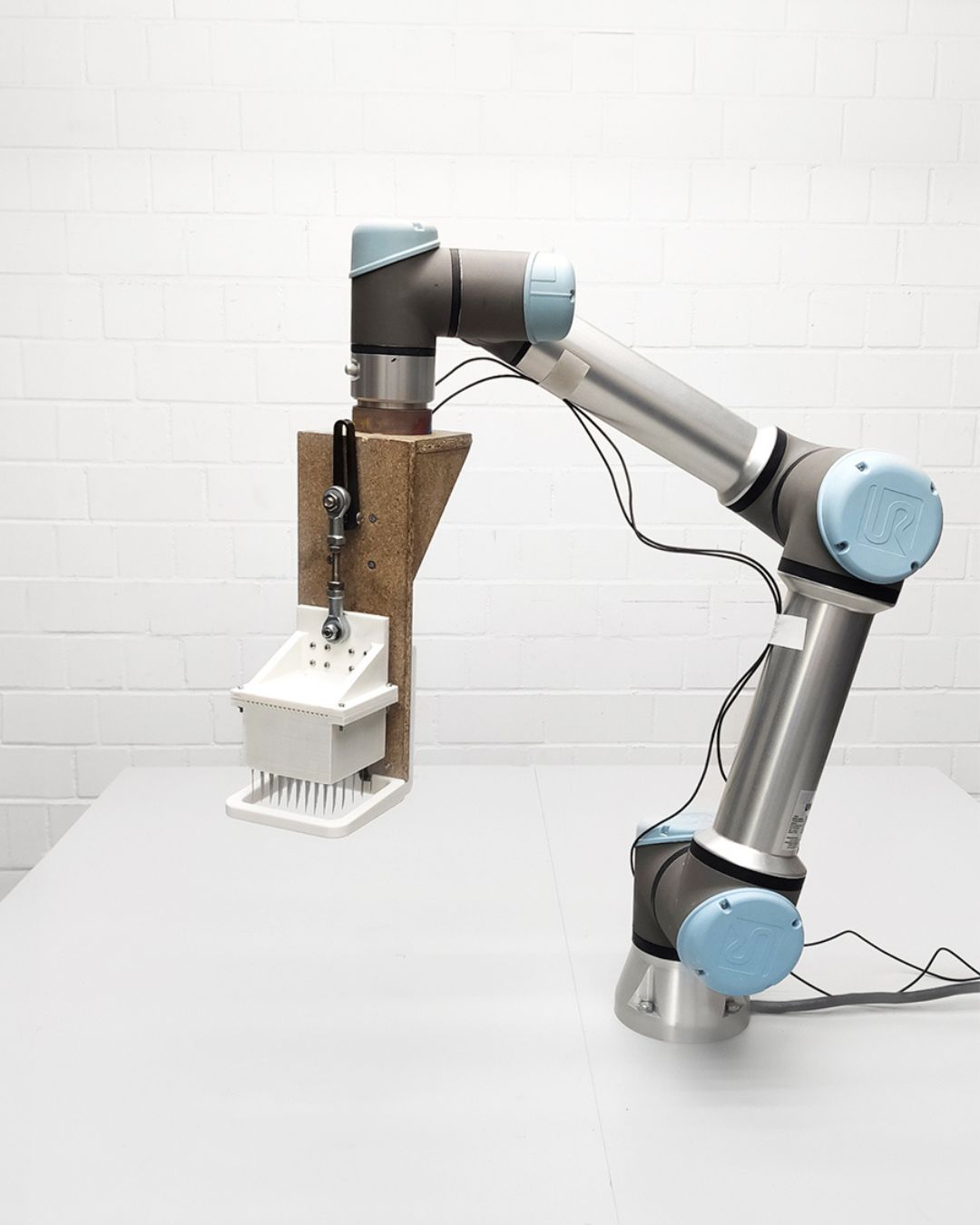

Baumeister uses a robotic arm equipped with a custom felting needle, allowing precise and repeatable control for production in series. By adjusting the speed and intensity of the needle insertions, the machine can control varying levels of stiffness across one object. Furthermore, it allows the possibility of creating three-dimensional structures using only one material. Rooted in the European artisanal felting tradition, Flock proposes a new way of looking at addictive manufacturing, which is generally associated with synthetic materials and high-tech practices.

Gallery

Open full width

Open full width

A key aspect of Flock is its mono-material strategy, and its advantages are especially demonstrated in the stool created by Baumeister. Containing no adhesives and no synthetic reinforcements, the stool can be easily dismantled and possibly recycled, as well as made entirely from a renewable and biodegradable raw material. In contrast, conventional upholstered furniture is usually made of a variety of different materials, like wood-based panels with chemical binders, foam, which derives from fossil resources, and textiles, which are often synthetic as well. Flock stands out by simplifying this material makeup, and is also a challenge to designers: can you achieve functionality and aesthetics without relying on structural complexity?

Additionally, as with any upholstered furniture, Flock will have to be re-felted from time to time, however, Baumeister has found the way to turn this apparent defect into a product strength. Through re-felting, the user has the opportunity to redefine the furniture themselves. The re-felting process allows for the selection of an alternative fibre structure and wool colour, the addition of new modules, and the felting of existing modules with other firm and soft areas. The designer also highlights that the older wool will never be taken away and will always remain in the inner structure of the object, so the previous felting cycles can be seen in its cross-sections, like the rings of a tree.

More than a single object, Flock is a material production system. Its machinery can be recreated locally, allowing for experimentation with different kinds of wools, colours, and regional design styles. Supporting a decentralised production model, Flock points to a future of on-site robotic felting that can be tailored to local waste streams. It also reframes waste as a resource, reintroducing value into a material we’ve written off. Furniture is only an example; using the properties of wool, the material can be used for architectural insulation, interior systems, and maybe even infrastructure.

What this project demonstrates overall is that design requires new systems, not just new materials. Baumeister’s project succeeds because it tackles sustainability by dealing with multiple layers at once: waste management, additive robotic fabrication, and locally based use, without forgetting about functional and aesthetic design. Perhaps the future of furniture lies not in creating more materials, but in finding out how much the materials we already have can become.