Paper Factor: an interior design revolution that starts with Papier-Maché

Paper Factor represents a contemporary innovation in the art of papier mâché, exploring its expressive potential in the field of interior and product design.

Could a humble sheet of paper transform not just the look, but the sustainability of your living space? In an age where eco-consciousness is increasingly vital, rethinking traditional materials becomes more than a trend—it’s a necessity. Imagine a product that not only embraces the versatility of paper but also brings a fresh, innovative approach to decorating your home.

Enter “Paper Factor,” a revolutionary line of paper-based interior design products that blend aesthetic appeal with environmental responsibility. Developed in collaboration with the University of Salento, Paper Factor is a solid surface material made from a new compound of micro-paper, derived from recycled and FSC-certified wood.

The Legacy of Lidiana Miotto and Paper Factor

Developed over 35 years ago, Paper Factor has its roots in the popular crafting technique of papier-mâché, which involves using a mixture of paper and adhesive to create a malleable material. This unique cellulose compound was meticulously tested and refined by the esteemed restorer Lidiana Miotto, founder of the Centre for Paper Restoration of Lecce (Centro Restauro Materiale Cartaceo).

Today, this legacy continues with Miotto’s son, Riccardo Cavaciocchi, who has adapted the cellulose compound through meticulous testing and refinement processes established at the Centre for Paper Restoration of Lecce. As a result, Cavaciocchi has innovated new applications and techniques to enhance the material’s versatility and appeal, introducing decorative wall panels and textured surfaces that offer a unique, eco-friendly aesthetic.

Cavaciocchi has also innovated with various textures, finishes, and colours to suit diverse design styles, while enhancing the material’s durability and ease of installation, making Paper Factor both practical and visually appealing for modern interiors.

From paper to perfection

Creating Paper Factor is a meticulous endeavour that marries traditional craft with contemporary innovation.It begins with the careful collection and preparation of raw materials, notably recycled paper sourced from diverse origins to ensure sustainability. This paper undergoes a transformative journey, shredded into fine pieces and soaked in water to soften its fibres. Blended into a pulp with a natural adhesive mixture, often derived from starch or cellulose-based glues, the concoction becomes the very essence of Paper Factor’s versatility.

Once mixed, the pulp is shaped and moulded into various forms, ranging from intricate panels to textured sheets, each bearing the imprint of skilled hands and thoughtful design. As the material takes shape, it undergoes a meticulous drying process, either through patient air drying or controlled oven treatment, ensuring its integrity and resilience. Refinement follows, with surfaces textured to perfection, achieving the desired tactile and visual appeal. Through sanding and specialised techniques, the unique character of Paper Factor emerges, ready to grace interior spaces with its distinctive charm.

But the journey doesn’t end there. Each piece undergoes rigorous quality control, where inspections and tests ascertain that only the finest examples bear the Paper Factor name. Finally, the products are meticulously finished, whether through painting, coating, or sealing, to enhance both their aesthetics and durability. This holistic approach ensures that Paper Factor not only meets the highest standards of craftsmanship but also embodies a commitment to sustainability and excellence in interior design.

Versatility in design and function

The exceptional qualities of Paper Factor stem from its meticulous manufacturing processes, resulting in a product that boasts an impressive resistance to mould, parasites, and fungi. Additionally, its water-repellent and stain-resistant properties make it ideal for a variety of applications, while providing effective sound and thermal insulation.

The raw materials used in its creation are sourced from either recycled paper or FSC-certified forests, reflecting a commitment to sustainability. What’s more, the dyeing process utilises natural pigments and energy-efficient machinery, with 70% of energy conservation achieved, supplemented by 30% sourced from solar power. This emphasis on eco-friendliness extends to the manufacturing process, which ensures all products are reusable and re-convertible, significantly reducing industrial waste.

Discover Paper Factor

Paper Factor represents a contemporary innovation in the art of papier mâché, exploring its expressive potential in the field of interior and product design.

Paper Factor’s various applications depend on these various steps, specifically the moment the impasto is mixed with natural pigments before being expertly pressed into moulds by hand and allowed to dry slowly. This versatile material can be shaped into an array of 2D or 3D forms, and in various colours, offering a versatile range of formats, colours, and combinations.

Following drying, each piece undergoes careful trimming, calibration, and polishing, a process carried out both manually and with the precision of CNC machines. From large panels to intricate mosaic-like modules, it can be seamlessly applied to ceilings, walls, and furniture. According to Paper Factor, its wide range of applications in architecture and design also include interior furniture, automotive design, and yachts.

Paper Factor’s products

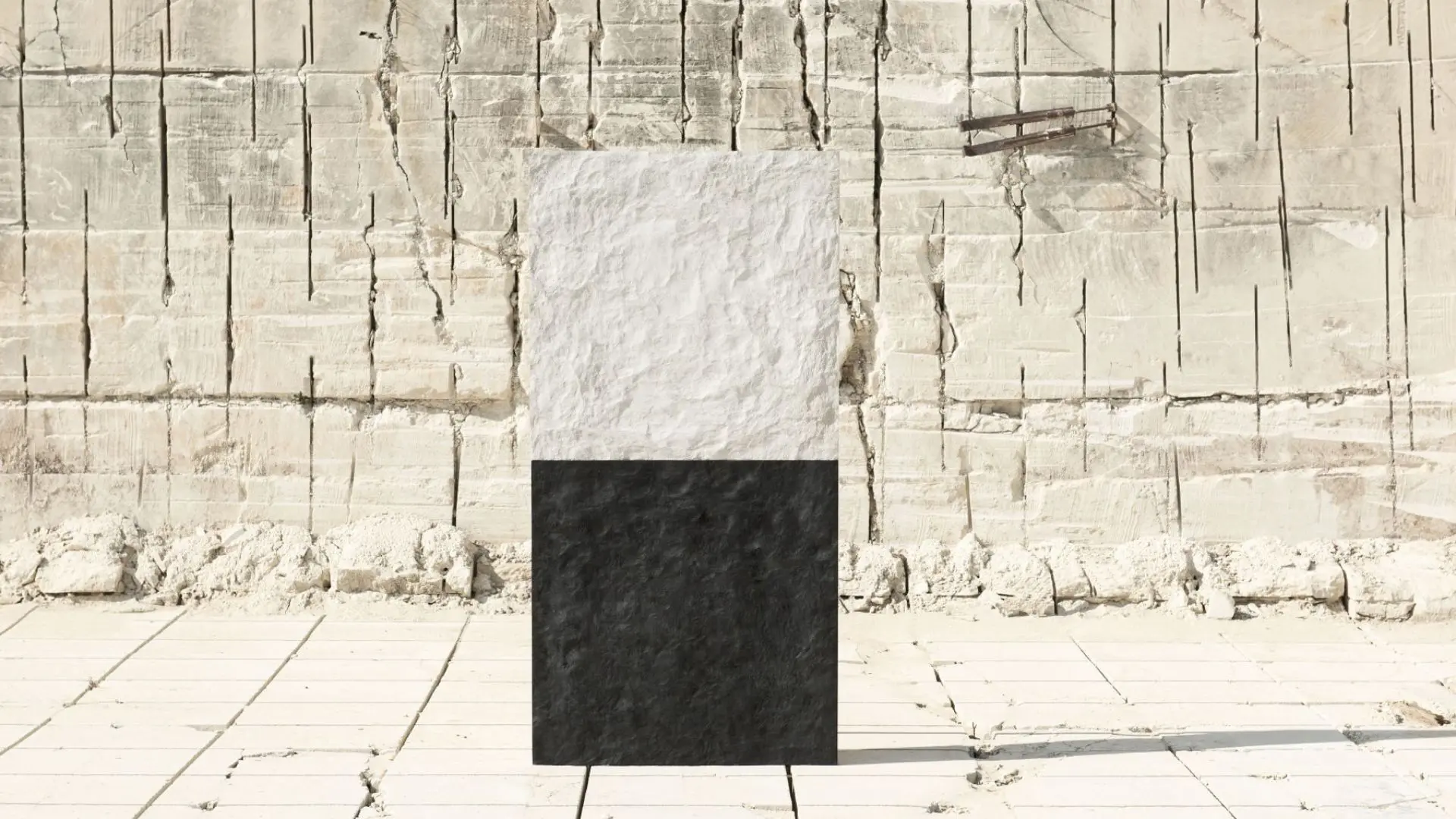

Paper Factor’s innovative approach to materials is exemplified in its diverse range of product collections, each meticulously crafted to transform interior design applications. Central to their production are skins and solid elements, designed to create striking 3D scenarios with unique textures and patterns.

Handcrafted and machine-assisted, these skins blend tradition with modern experimentation, embracing the beauty of imperfection. Customizable even in their standard forms, they reveal their artisanal origins through variable mixtures, textures, sizes, and patterns, bringing life to walls, ceilings, furniture, and other surfaces.

Among these collections, the Veins collection stands out with its pigmented veining that flows along the sides of a neutral-coloured impasto, evoking natural elements like marble, stone, wood, mosses, and lichens. This technique, achieved through gradual manual pressure, creates a spatiality defined by the interplay of light and shadow, adaptable to a wide range of design solutions.

Inspired by the ancient art of intarsia, the Inlay collection features surfaces where cellulose paste components blend seamlessly with pigments or natural tones during pressing and assembly, resulting in captivating spotted effects and defined shapes. In contrast, the Ruts collection showcases surfaces with grooves created by stretching the impasto by hand and using CNC machining. This process amplifies the material’s uniqueness and durability, exposing the very fibre of the paper and pushing it towards new dynamic and formal boundaries.

The Informale collection offers a texture with the highest tactile value, featuring hand-stretched and hammered surfaces that achieve a distinctive feel of solids and shallows, pressure marks, serrations, and natural curls. Meanwhile, the Piano collection embodies subtle elegance through its machine-polished surfaces.

Achieving durability and sustainability with Paper Factor

In the above formats, Paper Factor evolves through collaborations with designers and architects, offering limitless pattern possibilities and pushing the boundaries of papier-mâché. During Milan Design Week 2022, Paper Factor collaborated with Tom Dixon to create a “Sustainable Sarcophagus”, a remarkably lightweight coffin, owing to the unique composition of Paper Factor’s cellulose compound. A year later it collaborated with Italian designer Frederico Peri and luxury automotive brand Bentley to introduce the Thames table, which features a smooth, veined appearance resembling marble. Through these high-profile projects Paper Factor demonstrates its diverse applications whilst exemplifying a commitment to both creativity and environmental responsibility.

Lightweight yet durable, the compound material is designed to meet the demands of contemporary architecture while embracing sustainability. Paper Factor is designed for seamless application on walls and ceilings, ensuring stability and continuity with an integrated joint system achieved through milled channels. These panels, mounted on 10mm-thick wooden supports like poplar plywood or marine plywood, are ready for easy interlocking assembly using standard methods such as clips, bayonets, screws, and glues.

Typically, Paper Factor panels do not require joins, but if desired, common stucco for wood or masonry surfaces can be used, mixed with pigments to match the desired colour. Additionally, the edges of the panels can be chamfered upon request for a more refined finish. To enhance durability, Paper Factor offers protective treatments that resist stains and increase resistance to wear and tear.

Customers can also request variations in surface finishes, including colourless wax and specific treatments for a customised appearance. Regular reapplication of these treatments is recommended to maintain the panels’ appearance and durability. Through these features, Paper Factor ensures that their products are not only visually striking but also practical and long-lasting, providing a reliable solution for sophisticated interior design.

Developed over 35 years ago, Paper Factor has its roots in the popular crafting technique of papier-mâché, which involves using a mixture of paper and adhesive to create a malleable material.