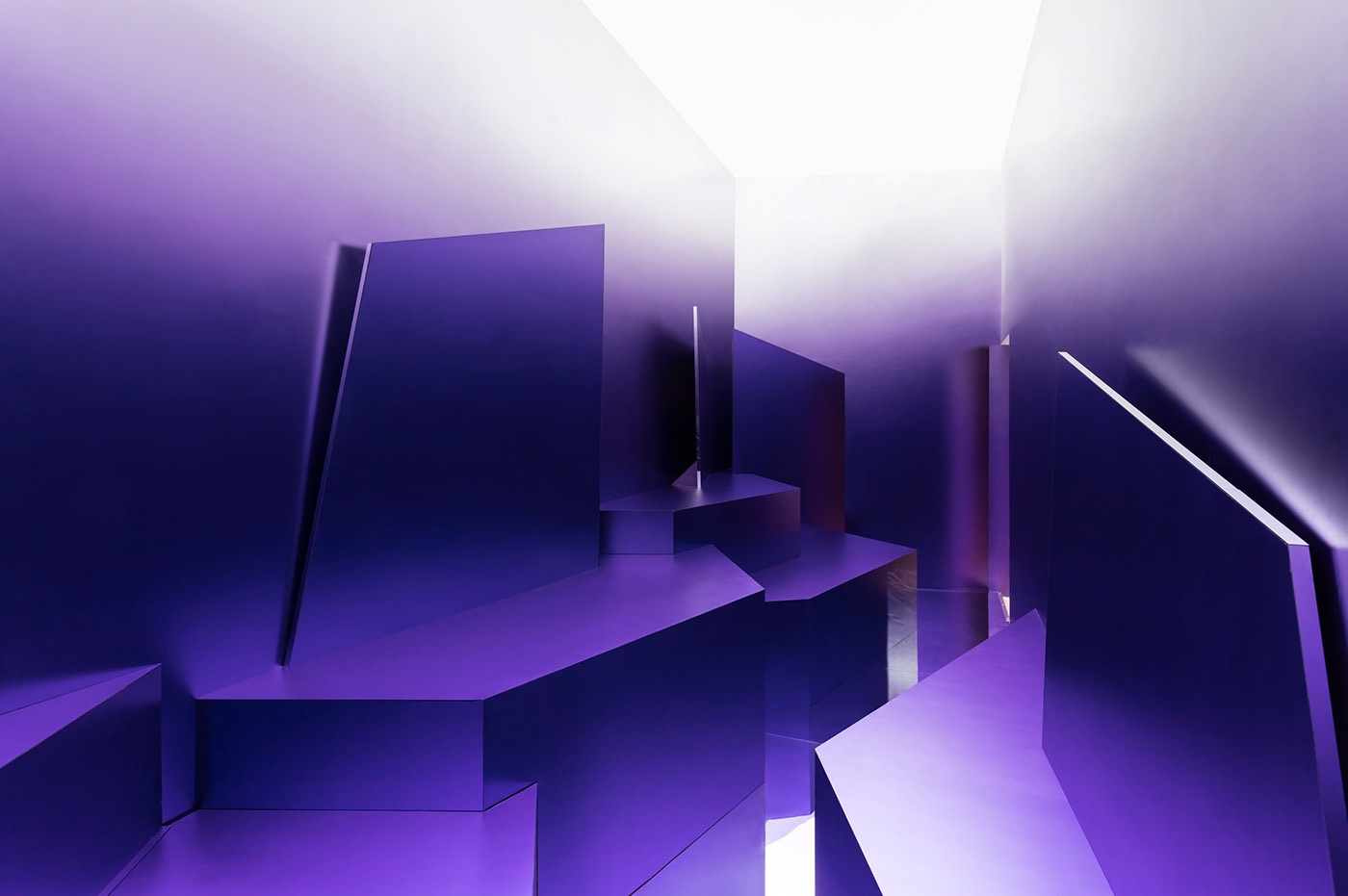

An inventive architectural solution designed to address urban heat challenges

TerraCool taps into the cooling potential of hollow ceramic components, drawing inspiration from advanced heat exchangers.

Created by Architect Dilara Temel and Industrial designer Lachlan Fahy, TerraCool, that was showcased during Dutch Design Week 2023, presented under the theme of ‘Urban Oasis’, employees ceramics for passive cooling via evaporation.

Its distinctive minimal surface geometries not only improve cooling effectiveness but also bolster structural integrity, enabling effortless incorporation into architectural designs.

Gallery

Open full width

Open full width

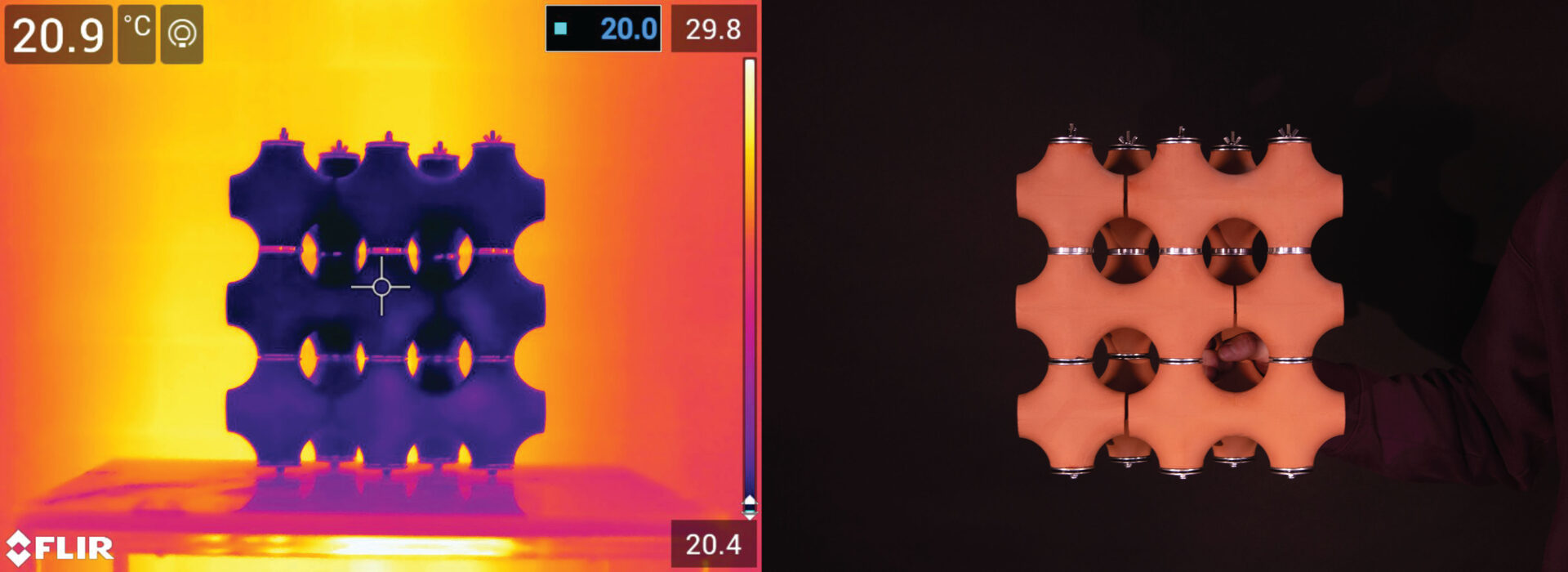

Passive cooling through evaporation

The proposal harnesses the inherent qualities of fired terracotta, capitalizing on its natural porosity to generate a cooling effect. This time-honored method, practiced in regions like Iran, India, Egypt, and Spain, serves as the core inspiration for TerraCool’s pioneering solution. As water infiltrates the ceramic surface and evaporates, it efficiently cools the surrounding air.

This groundbreaking project taps into the cooling potential of hollow ceramic components, drawing inspiration from advanced heat exchangers. Urban heat islands have emerged as a pressing challenge, impacting urban living conditions and public health. TerraCool offers an affordable and accessible passive cooling remedy employing ceramics to create more comfortable urban environments.

It represents an architectural proposition developed to counter the escalating issue of urban heat by harnessing the porous attributes of ceramics for passive cooling through evaporation. Its inventive utilization of minimal surface geometries enhances cooling efficiency and structural integrity.

The project by Lachlan Fahy and Dilara Temel aims to facilitate the seamless integration of evaporative cooling within architecture through its modular design, parametric adaptability, and manufacturing ease.

Inventive geometric structure

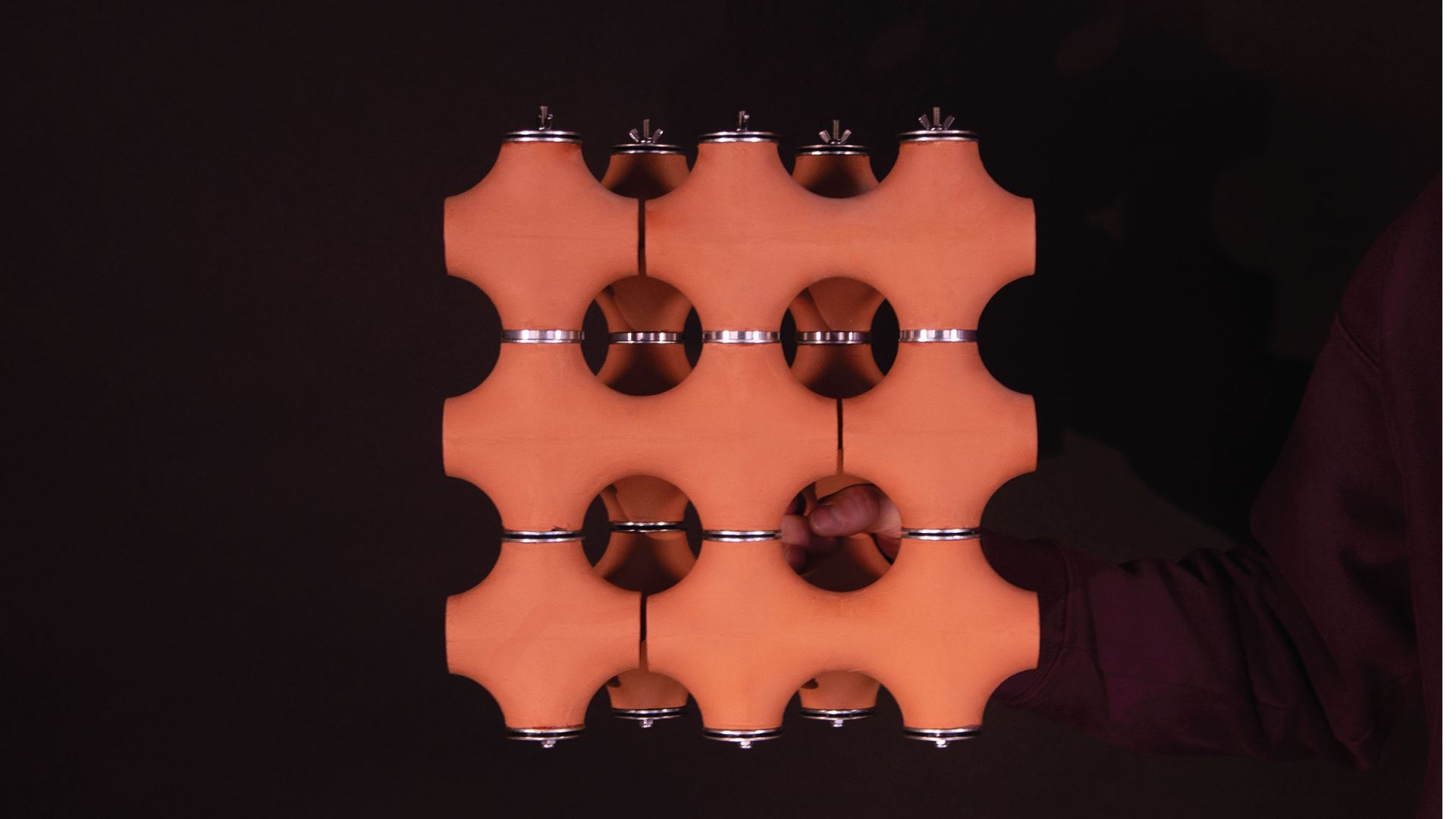

The design revolves around hollow geometries, emphasizing the highest possible ratio of surface area to internal volume. This facilitates interaction between the ceramic surface and the air. The inspiration for this geometry is drawn from triply periodic minimal surfaces, influenced by research in advanced heat exchangers for power plants.

The geometric requirements for heat exchangers share similarities, necessitating separate, interpenetrating channels with a substantial volume-to-surface area ratio. Moreover, the smooth geometry allows fluid flows to move freely without resistance. Aerodynamic shapes have been proven to enhance evaporation in ceramic evaporators.

Minimal surfaces also exhibit robust structural integrity, a crucial factor for TerraCool, as the geometry must support its own weight and the water it contains.

The design process behind TerraCool

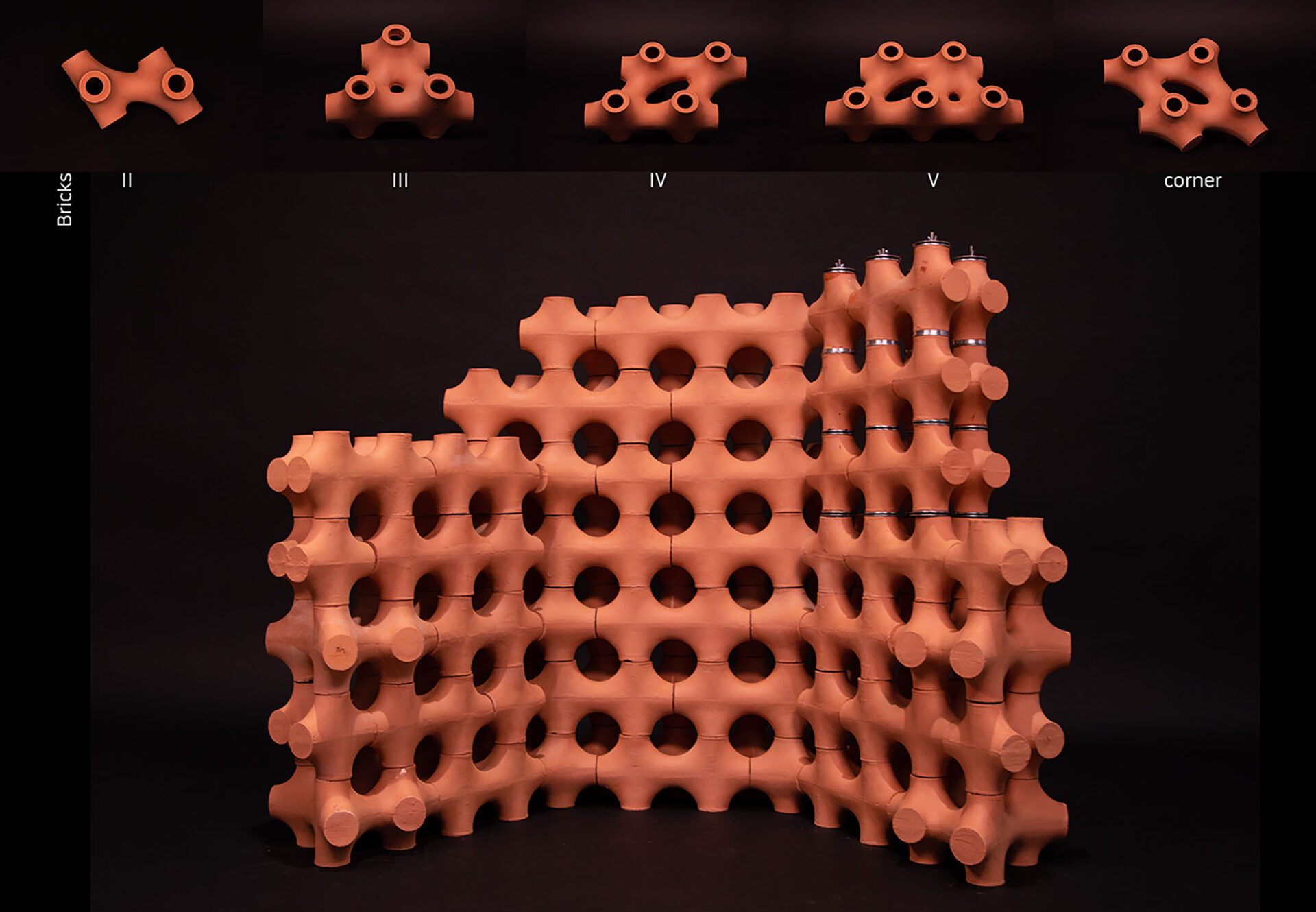

The design process adopts a meticulous approach that harmonizes tradition with cutting-edge techniques. It commences with the creation of modular hollow ceramic bricks through a parametric design system, utilizing input parameters to generate curves.

These curves are seamlessly interconnected to form the surfaces comprising individual TerraCool units. The subsequent phase involves fabricating these units using subtractive or additive manufacturing methods, ensuring precision and efficiency.

What sets this solution apart (here is another example of terracotta cooler we wrote about) is its innovative use of these positives as molds for various brick variations, reducing manufacturing time and enabling mass customization. Adaptations can be made based on local climatic factors, allowing designs to be tailored to specific environmental conditions and available water sources.

In essence, TerraCool’s design process represents a fusion of contemporary digital technology and traditional craftsmanship, resulting in a versatile and sustainable cooling solution.