Stack and Stack by Haneul Kim: ‘Unstacking’ pollution one stool at a time

Based in Seoul, Haneul Kim is a young designer who has created an eco-friendly furniture solution by melting together discarded face masks into a unique stool he calls “Stack and Stack”.

With an ongoing global pandemic, 130 billion disposable face masks are discarded worldwide every month.

While face masks are necessary to our health, this astronomical number has contributed to the massive issue of plastic waste in our planet.

Bothered by this, South Korean young designer Haneul Kim has come up with an eco-friendly solution for the upcycling of single-use masks, a clever stool design called Stack and Stack.

Collecting the discarded masks from his school, the Kaywon University of Art and Design, Kim was able to bring his stools to life by melting the masks together and molding them into shape.

The result is a clever design and an inspiring example of designers taking action and addressing pressing problems through a creative lens.

Impressed by the creative solution, DesignWanted had the opportunity to interview Haneul Kim and found out more about his design journey, the design process behind Stack and Stack, and what is next for the young designer.

Who is Haneul Kim? How did your journey in design begin?

Haneul Kim: “I am 23-year-old designer Haneul Kim who is active in Seoul, Korea and graduated from Kaywon University of Art and Design. I’m making furniture out of upcycled discarded masks, a big problem caused by the pandemic crisis.

When I was young I became curious about design under the influence of my mother who is a furniture designer, and I didn’t have my own personality, but I finally became a designer who deals with eco-friendly projects.”

Why Stack and Stack? How did you come up with this project?

Haneul Kim: “Due to the corona crisis, a huge amount of masks are being thrown away, and they just “stack” up. I collect and recycle masks that are discarded like that.

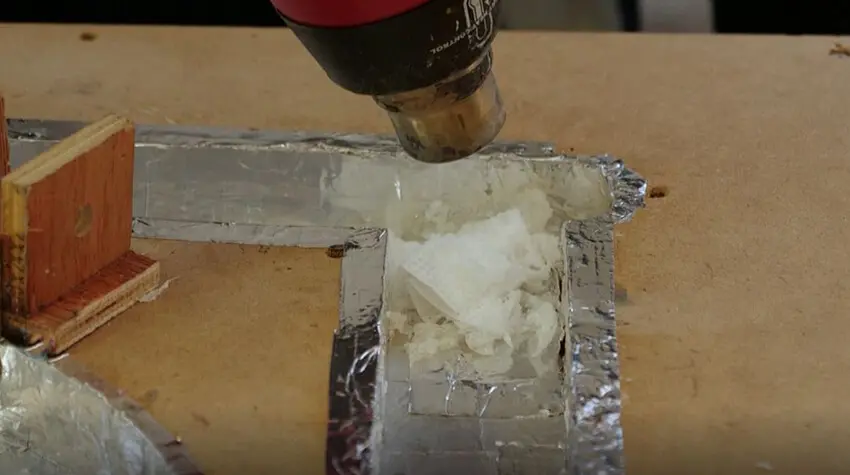

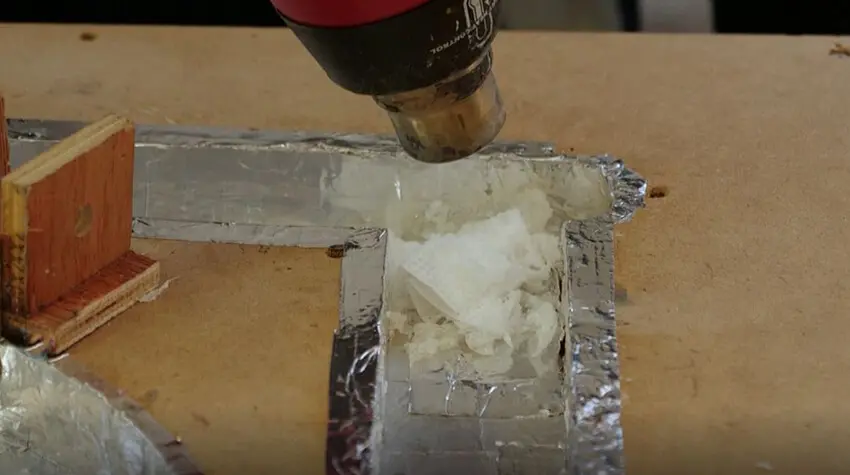

I make a mould with the legs of the chair and the shape of the seat, then melt the mask using a hot wind and keep “stacking” them up.

By combining the legs and the seat of such a chair, they are designed to be “stacked” together.

I wrote down the manual for my work and felt the word “stack” overlap a lot. That’s why it’s “stack and stack.”

Since Corona, 130 billion disposable masks have been discarded per month worldwide.

I knew that the material of the disposable mask was plastic, and such discarded masks threaten wildlife and the ocean, they wear out with microplastics and eventually return to our bodies.

Plastic recycling is possible, so why not recycle masks that are made of plastic? It seems to have started out of curiosity.”

Can you tell us about the research and experimentation process that took place in order to define the material?

Haneul Kim: “I decided to recycle the masks, but not everything worked out well from the beginning. I first tried to boil the masks in boiling water and used fire directly with a lighter.

After all the failures, I had an idea. If it’s a plastic mask, let’s refer to the process of plastic recycling!

So I studied the process, and at the end, I was able to recycle the mask using high-temperature wind. I tested hundreds of temperatures, humidity, drying times, etc.

I was finally able to melt the non-woven mask into a liquid resin state and cool it again to harden it.”

Get a deeper insight into Haneul Kim’s design, don’t miss Disposable masks repurposed into Stack and Stack stool by Haneul Kim: let’s examine plastic recycling.

How did you go about your prototyping phase when designing the stackable stools? What steps did you take to arrive at a final prototype?

Haneul Kim: “At first, the mask was melted in a small can lid.

That was the beginning of my work, and the resulting material was really hard and even the texture was beautiful.

I was sure that it wouldn’t be difficult to scale up if I used the process because it was successful.

So, without hesitation, I made a form of chair that I designed and made a chair.

This time, instead of just using the usual white mask, I tried to create various textures using coloured masks such as black, blue, and pink.”

What is the hardest part of the process of working with recycled plastic?

Haneul Kim: “There were concerns about hygiene and secondary infections.

Because Corona is a really serious situation, many people are sensitive and worried.

Conventional viruses, such as SARS and MERS, usually die at 50 to 60 degrees Celsius, but the coronavirus dies close to 100 degrees Celsius.

For reference, the temperature of the hot wind I use is well over 300 degrees.

I have to persuade a lot of people in the future, and that’s the most difficult and interesting part.

Interestingly, I am currently planning a hygienic work on the fabric of a small mask that occurs in the process of its manufacturing.

In fact, as many as 10 percent of the fabric is discarded during the process of mask manufacturing.”

What’s next for Haneul Kim? What new projects are you working on?

Haneul Kim: “Currently, a huge amount of requests for coverage have been pouring in, both at home and abroad.

I think I have a duty to repay so much attention and love, and I believe I can make anything now that I made a chair out of recycled masks.

As a person who makes furniture, I will develop a series of tables and lights, and I hope that my technology will be reviewed on a national level to be viewed as good and practical.

Also, I am planning a great collaboration with companies that agree with me, so you can look forward to it.

I will study harder and do activities from now on.

Thank you for listening to my story.”

Did you know plastic can be reused as filament for 3D printing? Read all about it: The New Raw – From plastic waste to furniture with 3D printing