Pine tree resin for fully natural, biodegradable, composite materials

Ecopin, a patented biosourced, biodegradable and recyclable resin for the design of new biocomposite materials, is an alternative to synthetic binders, a blend of nature, science and design for resilient and ecological products

By studying and looking at local natural resources of New Aquitaine, in 2017 French company Arrosia started developing a new and alternative binder for composite materials industries.

Their mission was to promote forest co-products, resources they considered to be the expression of their territorial and environmental values.

The Origin

In their research, Arrosia found incredible potential for that purpose in the pine resin naturally produced by the trees in the Landes Forest.

They understood that such a product of nature could be refined and engineered via innovative processes to match the industry’s needs in terms of processability and expected performances.

Starting from one original basic formulation, they combine it with different fillers for keeping optimal structural maintenance in research and development service.

How it is used

The material is provided in granules and is definitely adaptable to many conventional thermoplastic processing technologies, such as injection molding, contact molding, thermoforming and thermocompression – all already successfully tested.

A new formulation for pellets used in Arrosia’s own injection production line is planned for the beginning of 2023.

Usually the material is combined with different natural fillers derived from local agroforestry co-products, that provide both mechanical performances and a very pleasant look & feel to the final product.

Both vegetal and mineral fillers can be used, giving a wide range of possibilities and control over parameters such as surface conditions, density, flexibility and elasticity.

Possible applications

This composite is ideal for small, convenient objects for the hotellerie or houseware sectors, where warm to the touch, smooth or rough textures and the substantial natural look are well perceived and appreciated.

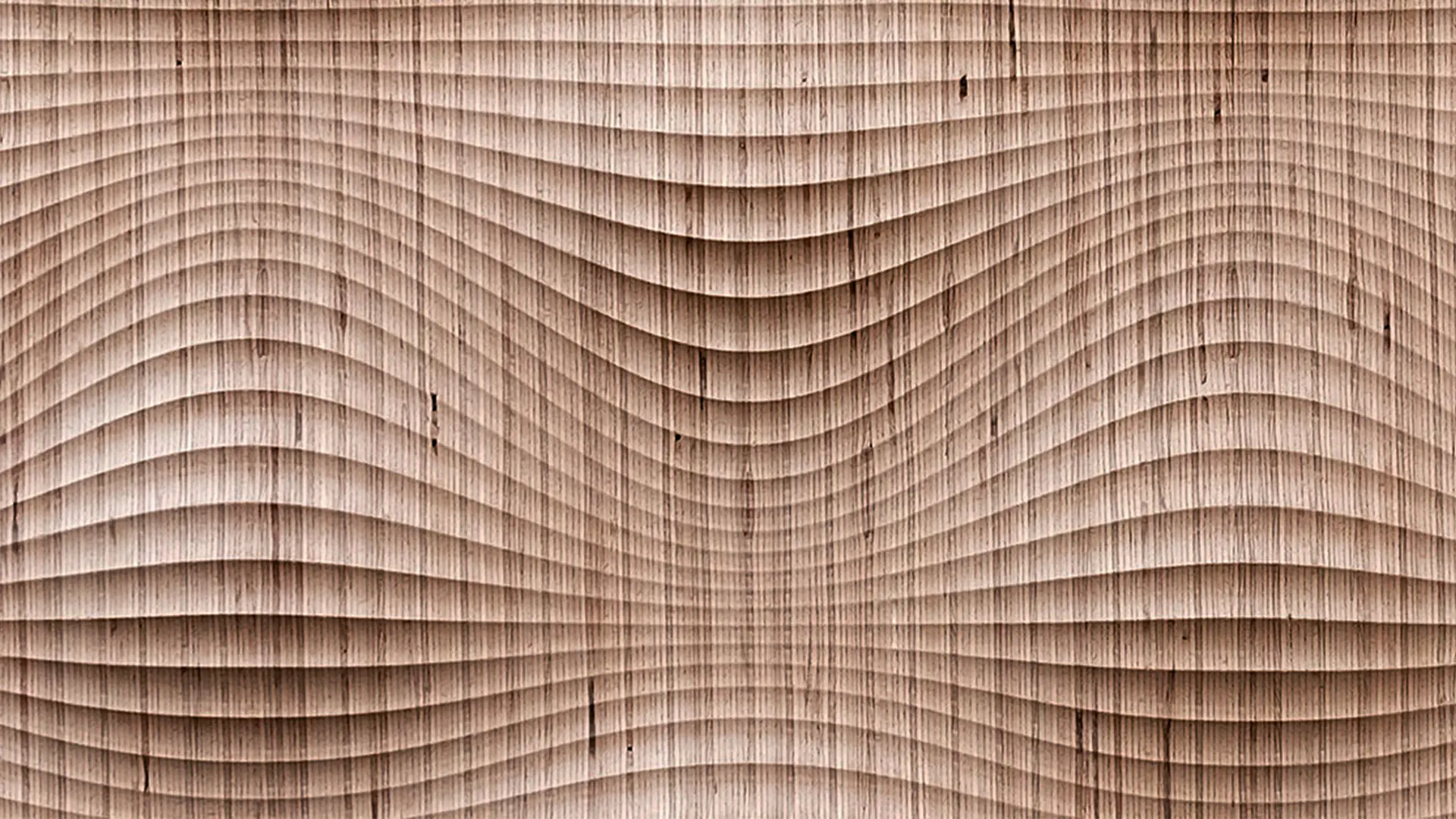

But thanks to further development and the wide range of manufacturing processes available, Arrosia also developed a system to produce structural panels for interiors and architecture made entirely of Ecopin and vegetable fibers.

These panels, provided under the name of PINHADAR, can also be cut and dyed.

Creativity & Design

When using this material for their creations, designers can co-develop and co-create the material itself with Arrosia.

Texture and final overall appearance can be achieved by choosing a natural byproduct as a filler, getting a more visible, natural look, or a mineral filler, getting a more uniform, plain coloured effect.

The co-development process includes a prototyping phase, where designers have the chance to express ideas and objectives of their own project, followed by Arrosia’s suggestions on the most suitable manufacturing process for the specific case.

By doing so, the designed product is effectively developed to reach large or small scale productions.

An eco-friendly solution

Currently, most composite materials used in product design still contain a significant percentage of synthetic, polymeric binders that ensure mechanical performances but have a negative effect on the end of life of the products.

Being composites, (even if often simply perceived as “plastics”), these materials can not be recycled with other plastic materials such as those used for packaging, and thus end up in landfills or get incinerated most of the time.

Arrosia’s Ecopin, which is naturally extracted, thanks to its overall vegetal composition results in a much more eco-friendly solution, since it can potentially biodegrade and its components are commonly found in nature.

This material is a great choice for reducing the overall environmental footprint of a final product, promoting a sustainable approach in responsible, eco-driven design.