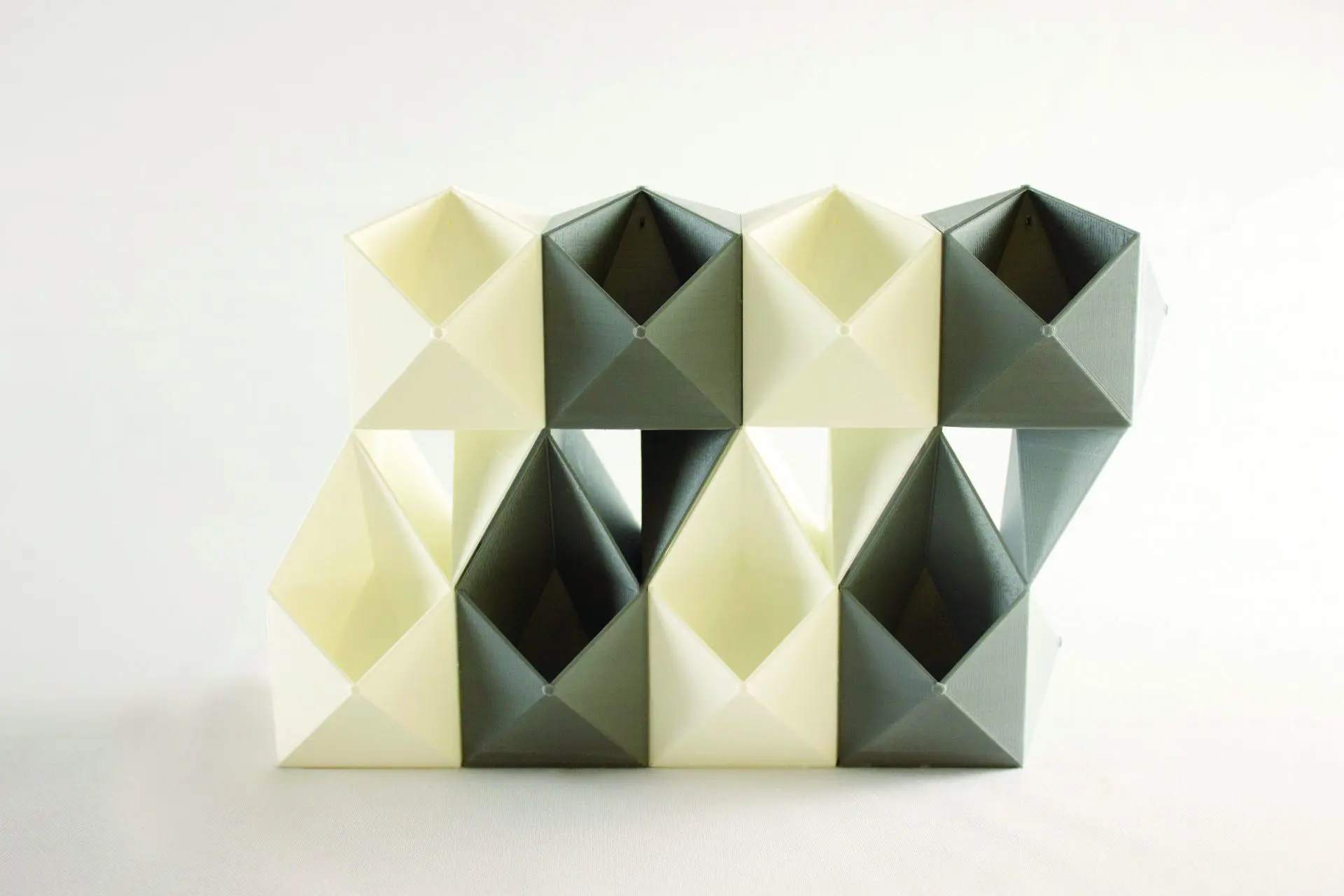

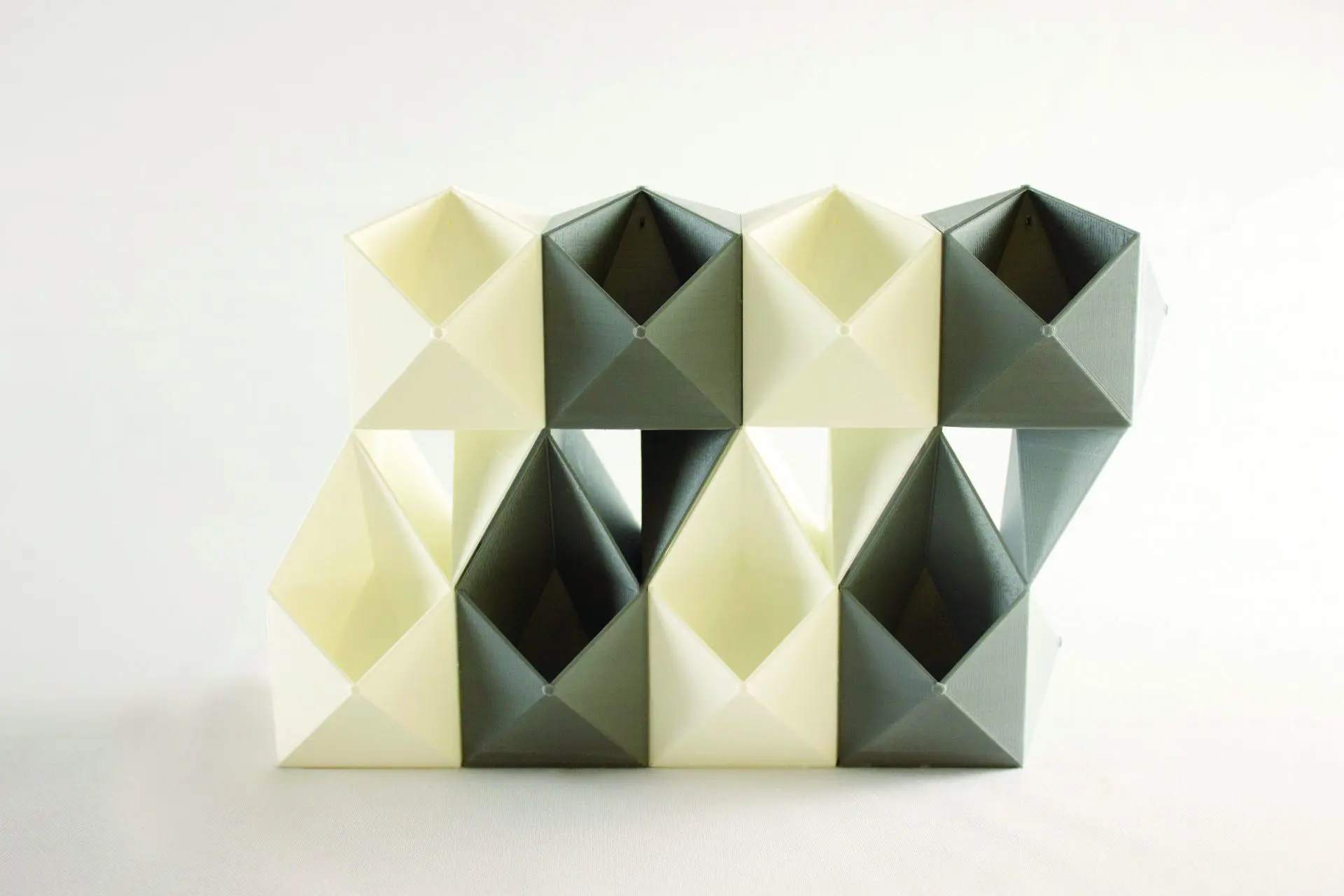

YX planter is an “architectural product” with a modular system for endless compositions

Y&X allows you to generate endless compositions in height and length, merging nature with a highly geometric robot-made creation

YX planter by Ernesto Pastore are prototype blocks manufactured with additive technology and serving different purposes in the interior space. 3D printing enables experimentation on multiple levels, from materials to shapes and design process, radically shortening the time required to evolve an idea to a concept to an actual prototype realization.

Easily used as planters, the infinite potential combinations of the two-block types can also serve a divider, filling empty spaces and regulating fluxes of people in commercial areas or hospitality spaces.

As 1 of the 10 winners of the contest ExpoWanted organized by DesignWanted for Milan Design Week 19, we had a chance to interview Ernesto Pastore, designer of YX to know more about the endless applications of this product.

Tell us about Project YX planter and what makes it a unique product?

Ernesto Pastore:

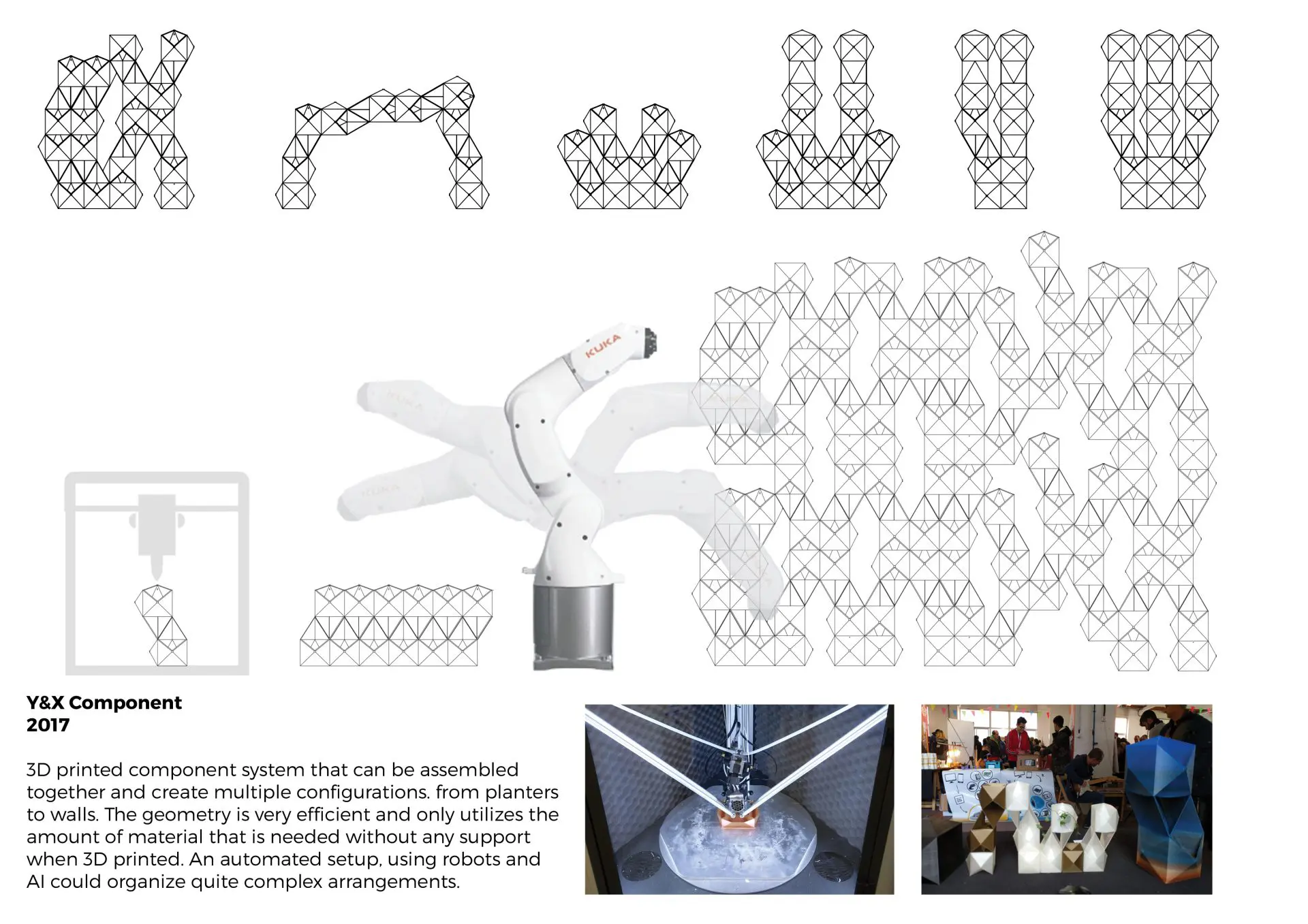

“My product is a family of 3D-printed components that can be assembled together in different configurations. The geometry is flexible in the way that it is possible to use it for different purposes, from planters, lighting fixtures and room dividers to large scale applications like walls or facades.

I think its uniqueness comes from its multiple uses and the way it can be configured and also about how it is produced. The model is completely parametric and therefore, fully customizable; the limit only being the volume of the machine that is used to fabricate it.

At the moment, for low scale production,the products can only be produced with additive manufacturing. Although 3D printing is currently not as fast as with other ways of production, it allows for the possibility to experiment with multiple materials and process.

For instance, with this model, no support or waste material is produced, the geometry is also designed, to be packed in a way that allows to reduce shipping to a minimum and the product can be printed on demand. For the prototypes of YX Planter, PLA, a plastic derived from cornstarch was used. But other materials are possible, for example, recycled plastic using pellets directly or bio-materials are exciting and interesting options.”

How was your experience with ExpoWanted?

Ernesto Pastore:

“I think it is a great opportunity for young designers to show what they can offer with a minimum investment. I found out about the competition on the last day it was available to register, through an Instagram campaign and decided to participate. The process was straightforward and the results were known quickly.

I also had the opportunity to visit the exhibition during Salone and was very satisfied with the effort made by the DesignWanted team.

I was not planning to go to Milan this year, but fortunately I happen to have a very last minute meeting with a company I just started a collaborating with, so I had the opportunity to visit the fair and meet the founders and the great people behind DesignWanted, it was exciting to hear from them all the plans they have for the future.

I would definitely participate again and would encourage people to try and submit their products, so far its been a great exposure for my designs and ideas.”

How does Project YX respond to current design trends?

Ernesto Pastore:

“More than following trends, I like to respond and propose solutions to current problems, I think cities and our environments need to become greener; not only for our own well being but also for that of the planet, and this is definitely possible with all the tools we now have available.

Specially by using computation, robotics, bio-materials, and renewable for energy, I believe we can curve global warming and fix this mess we have caused since the beginning of the industrial age.”

What was the hardest part in the development of YX planter?

Ernesto Pastore:

“The hardest part for YX Planter was to come up with a 3D printable model for a very complex geometry, this meant having a watertight model with a constant thickness that wouldn’t change in the geometry, as the parts needed to be very accurate and within tolerance to fit one another.

The inclinations of the walls also had to be considered in order to avoid the use of extra support material when 3D printed. Currently, acquiring funding is a special challenge to take this and similar projects further, as grants or capital investment and interest for this type of projects is basically in existent in my home country.”

What is the next step for Project YX?

Ernesto Pastore:

“I am open to any possibility; a producer as long a they take into consideration sustainable processes would be a good way to put the product into the market fast, but also a crowdfunding campaign is an option I have consider for some time.

Currently I am working on a better way to connect the model, and I am also working on other block/component systems.”

In your opinion, which reference sector does Project YX lie in?

Ernesto Pastore:

“I think YX Planter is flexible to fit various sectors, but specially the sustainability, customization, vertical gardens and home décor categories.”