The journey beyond death: establishing furniture’s sustainable afterlife with Eco-Mobilier

Founded as a non-profit environmental organization, Eco-Mobilier gives new life to discarded furniture by guiding collection partners, consumers and furniture companies towards a solid circular economy.

In 2011, 24 manufacturers and distributors operating in the French furniture sector set up a non-profit environmental organization called Eco-mobilier. They had the admirable aim to reduce used furniture environmental impact, by preventing it to end up in landfills. In order to do so, Eco-mobilier has been adopting and spreading circular economy principles since its very beginning.

Today, the eco-organization provides solutions for collecting, sorting, recycling, and reusing used furniture and mattresses, as well as worn-out duvets and pillows. In this way, Eco-mobilier helps private individuals and professionals to turn used products into tomorrow’s resources. Their environmental organization’s model is one-of-a-kind, as yet unparalleled across Europe, in terms of both scope and purpose.

On the occasion of Sustainable Furniture Week, DesignWanted had the opportunity to interview Eco-mobilier, discovering more about their journey, sustainable practices, advice about eco-design, current and future initiatives.

How did the journey for Eco-Mobilier begin?

Eco-mobilier: “Created in December 2011 by 12 retailers and 12 French manufacturers, Eco-mobilier is the eco-organization approved by the French public authorities to manages the collection, sorting, recycling and waste energy recovery of all used furniture and that promotes its reuse with regards to the Extended Producers Responsibility (EPR) regulation.

Our mission is to reduce the furniture environmental footprint all along its life cycle, from cradle to grave. To fulfil this mission, in France since May 2013 an eco-tax has been applied on every piece of furniture in addition to their purchasing price by all retailers and manufacturers.”

Caring about products life-cycle is a design opportunity and a must according to the United Nations’ SDGs. Let’s find out how Klaus Jorlet of We Do Wood is linking UN’s Sustainable Development Goals to furniture design!

Eco-mobilier: “Eco-mobilier accounts for more than 5’000 members. Since its foundation, Eco-mobilier has collected nearly 3 million tons of discarded furniture, 95% of which has been recovered (either through recycling or energy valorization). Eco-mobilier aims for ZERO furniture going to landfill by 2023.

In October 2020, Eco-mobilier launched “Maison du tri”, the partner that provides the end customers with all the solutions and points of collection to help them properly tidy up, sort and recycle their furniture, bedding and household items.”

Eco-Mobilier has been giving new life to used furniture, mattresses, and even worn-out duvets and pillows. Could you tell us more about the journey of a piece of furniture after it has been thrown away by a consumer?

Eco-mobilier: “People wishing to get rid of a piece of furniture usually have two solutions at their disposal: either they take it to a waste disposal center and put it in a dedicated Eco-furniture bin, or, in the case of large cities, a collection service picks them up in the street.

Once discarded, this furniture is collected by our waste operator partners who sort the different materials, most of the time automatically via machines. Once sorted, some of these materials undergo a preparation process so that they can be reused as raw materials by other manufacturers.

It is therefore possible that your old mattress has found a second life as an insulation panel for example! The rest is recovered energetically, to feed the boiler room of a cement manufacturer for instance, and thus avoid the use of virgin natural material for this kind of use. Our resources are limited, let’s preserve them!”

The furniture and products Eco-Mobilier recycle come in a variety of materials. What is the recyclability performance of the different materials you encounter? How do you research and experiment with innovative solutions to improve the recyclability?

Eco-mobilier: “In furnishing, we find a variety of different materials. It is mostly wood panels but there are also textiles, foam (polyurethane or latex), metal, plastic, glass… Some of these materials are easily recyclable and the associated techniques are well mastered by major industrials. This is the case of metal for example.

In other cases, it is more complicated. Let’s take the example of a wood panel. Generally, it is made of wood fibers or particles mixed with glue and covered with a melamine or PVC varnish for the finish. The fact that these materials are glued together is a problem because the wood fiber that comes out after the panel is grinded is of lower quality than virgin fiber.

We are therefore constantly monitoring and identifying new technologies that will enable us to solve these challenges. On the subject of wood, we will very soon be launching a call for research projects to test tomorrow’s solutions in terms of recycling and recovery.”

In your opinion, how big is the role of the designer in the product system for a sustainable object?

Eco-mobilier: “Taking into account the end-of-life of a product right from the design phase is paramount if our industry is to fully enter into a Circular Economy logic. The designer is the first link in the chain and therefore has a key role to play. He is the one who decides how easy it will be for us to add value to the furniture he has created when it reaches the end of its life.

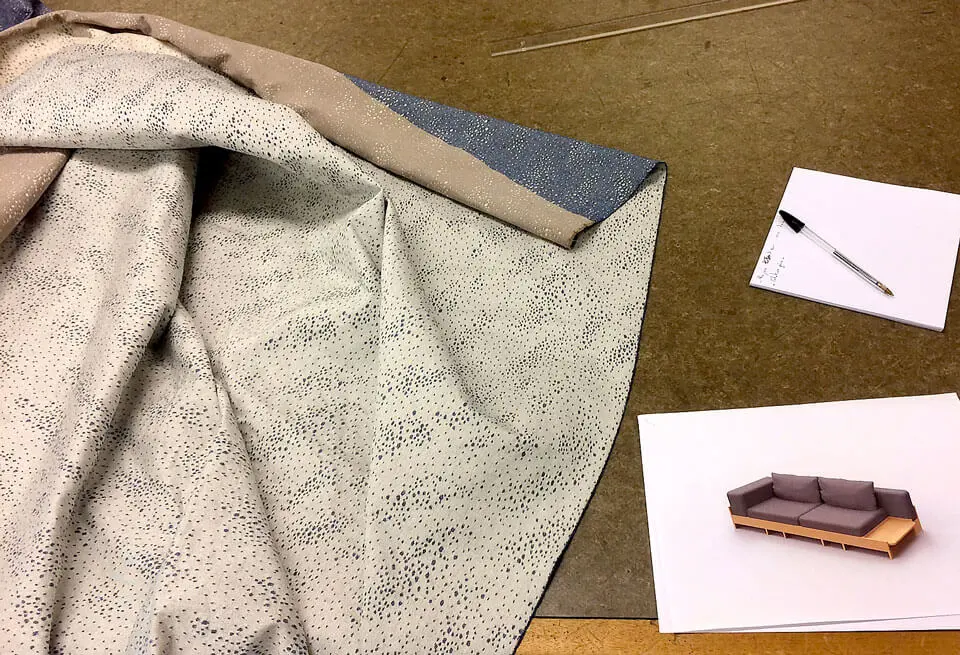

From our point of view, one of the best ways to integrate the end of life in the design process of a piece of furniture is for the designer to be aware of the problems that arise when sorting and recycling furniture. This is why we work closely with our members and educate them about the principles of eco-design. We thus give them visibility on the right questions to ask and the best practices to apply when designing a piece of furniture or a mattress.”

Eco-Mobilier promotes and fosters an innovative approach that aims at turning used products into tomorrow’s resources. What are the best practices to eco-design a product?

Eco-mobilier: “There are many different and complementary ways to eco-design a piece of furniture to improve its end-of-life. The first is obviously to work on the recyclability of the product by using recyclable materials, as few as possible and easily separable. In fact, the recyclability of a piece of furniture can be analyzed with regard to the recyclability of the main material composing the product. It is therefore important that the other materials used are easily separable from this main material.

The second is the use of recycled or reused raw materials. Recycled materials are virtuous from an environmental point of view; their use of new products must be further developed. Finally, eco-designing for end-of-life means preventing the production of waste and delaying the transformation of a product into waste.

We must therefore work to extend the “use-life” of products. This involves the multi-functional and evolutionary nature of products, but also their reparability thanks to easy disassembly and the availability of spare parts.”

What is next from Eco-Mobilier?

Eco-mobilier: “Indeed, we have much news in terms of innovation in the coming months. As said before, we will very soon launch a call for research projects aimed at improving the recycling of wood panels and finding new markets able to use the wood fiber from our old furniture.

In addition, we are organizing a second edition of the Innovation Day at the beginning of 2021, aimed at connecting our members with innovative design solutions. By the way, if among you, there are individuals that wish to share with us their innovative solutions, we have a dedicated website for that. It is with pleasure that we will study all applications!”

Curious to find more sustainable ways of using wood? Discover how Viewport Studio is facing the timber life-cycle challenge!