8 eco-friendly packaging alternatives companies should be using

From paper bottles to mushroom mycelium, paper-based and plant-based packaging are rightly regarded as being amongst the most environmentally friendly and sustainable.

In 2018, McDonald’s announced its packaging will be 100% renewable and recycled by 2025. After committing to a similar deadline for reducing its eco-damaging packaging, clothes retailer H&M announced more recently that it would begin shipping online orders in paper rather than plastic.

It is becoming easier for brands to commit to these plans for several reasons: public shaming and genuine concern for the environment being two of them. The one we are most concerned with, however, is the breakthrough in plant-based and compostable packaging, which are renewable and far better for the planet in most cases.

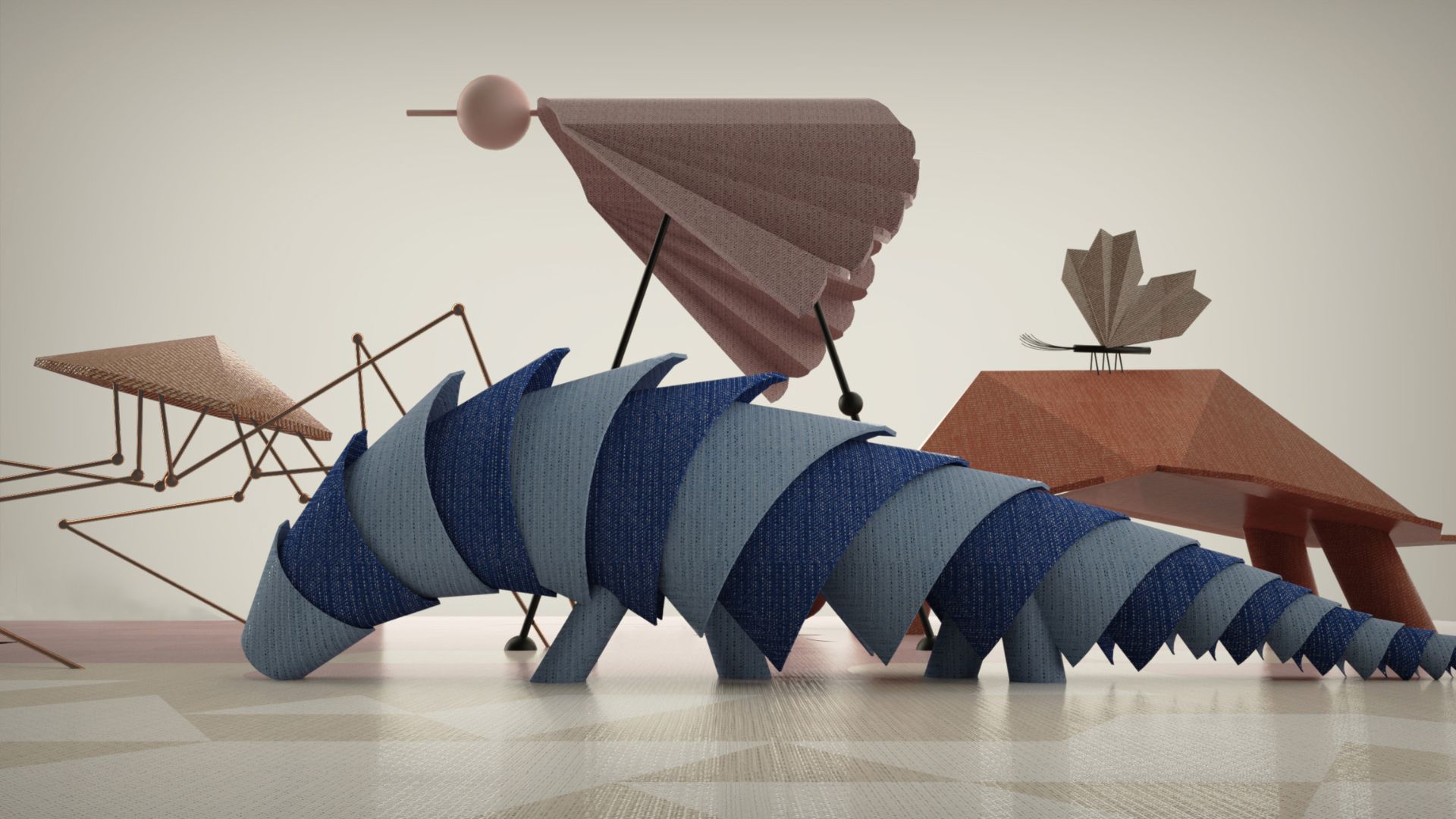

Gallery

Open full width

Open full width

Here, we highlight 8 eco-friendly packaging alternatives including paper bottles and six-pack rings that can be used to grow new crops after disposal.

Eco-friendly packaging – 8 project highlights:

Pack from Nature

Using renewable plant starches and biodegradable polymers, Pack from Nature is a 100% compostable packaging concept that claims to be as strong as a plastic bag. They are made from Polylactic acid (PLA), a plastic substitute that’s made from fermented plant starch, which is mixed with biodegradable plastic, Polybutylene adipate terephthalate (PBAT).

With the option to personalise the bags and compost them easily at home, the Pack from Nature concept caters to both business and consumer needs. It forms part of its mission to transform the retail and fashion industry. According to the company, it should take approximately 6 months for the bags to break down fully.

Paboco’s Paper Bottle Project

Founded in 2019, Paboco is a joint venture between paper packaging material developer BillerudKorsnäs and bottle manufacturing specialist Alpla. Together, they have developed a recyclable and 100% bio-based paper bottle concept made from a pine pulp mixture formed using 3D moulding techniques.

Earlier this year, they unveiled a prototype second-generation paper bottle that uses renewable paper to build strength and structure, supported by a bio-based barrier solution unique for each product. The current objective is to test different biobased coatings, including bioplastics while ensuring the quality of the contents isn’t compromised.

Mushroom Packaging

Developed by New York-based biotech startup Ecovative, Mushroom Packaging is a high-performing eco-friendly packaging solution grown from the roots of mushrooms, called mycelium. The process involves creating custom molds and growing the packaging to shape, which takes approximately 7 days.

It’s posed as a high-performing packaging solution compared to plastic packaging for several reasons. Firstly, because it has a decent shelf life (up to 30 years when kept in dry conditions). Mycelium is also flame and water-resistant, nutrient rich and fully biodegradable. Mushroom Packaging is also Cradle to Cradle Gold Certified and home compostable within 45 days when divided into 1 cubic cm pieces.

TIPA Sustainable Packaging

Using a patent-protected formula made from a blend of fully compostable polymers, TIPA creates compostable films and laminates that emulate the properties and functionality of conventional plastic materials such as Polyethylene and Polypropylene.

Competitive properties (achieved partly from the use of fossil-fuel based polymers) include high transparency and high sealing strength. Despite this, TIPA’s sustainable packaging has several redeeming qualities that highlight important considerations including high-barrier strength and printability. “Each of our films and laminates are compatible with flexographic and digital printing processes for high quality and high-speed printing,” the company explains.

Ecologic

Billed as “The world’s only commercially-viable paper bottles made from recycled materials”, Ecologic’s patented eco.bottle consists of an outer shell, made from recycled cardboard and newspaper, and an inner liner, made from PCR plastic boasting a 70% material reduction vs. rigid plastic bottles.

After use, the outer shell is recyclable and/or compostable, and the inner liner is recyclable. The manufacturing process uses molded fiber technology to produce paper bottle shells made from recycled cardboard and old newspaper, which are pulped into a slurry mix and transferred to a forming station. Heat and pressure are then applied to form a sturdy enough bottle. Ecologic uses custom equipment to produce thin, lightweight, collapsible liners and a proprietary integration machine to lock the components together.

PaperFoam

Based in the Netherlands, PaperFoam combines industrial starch, natural fibers, water, and a premix to create a home compostable material, which it has provided for brands including cosmetics company Schwarzkopf and Burt’s Bees, as well as mobile provider T-Mobile and tea brand Pukka. Formed through injection molding, which allows infinite freedom of design, detail and colours, the packaging is compostable, biodegradable, and paper recyclable.

It is also incredibly light, which decreases carbon emissions during transport, and the production of the material uses locally sourced renewable materials and is less carbon-intensive than the production of traditional packaging materials.

E6PR

Founded in Mexico, E6PR has been designing and manufacturing zero-waste packaging since 2017, including this six-pack ring made entirely of compostable agricultural byproducts. The rings avoid plastics, oil derivatives and other synthetic binding elements in favor of non-toxic biodegradable raw materials, which according to the company, the can-holders can be broken down and transformed into fertilizer to grow new crops.

The rings have received several awards in categories from environmental packaging and design to public relations. In 2019, the rings started holding together cans from Corona in Tulum, Mexico. That’s not bad considering E6PR whipped up their first prototype using a 3D-printed mold and standard home oven.

Notpla

Founded in 2014 by designers Rodrigo Garcia Gonzalez and Pierre-Yves Paslier, the company’s products feature the company’s blockbuster product Ooho, an alternative to plastic made from seaweed that is edible and fully biodegradable in just 4-6 weeks without the need for industrial composting or special conditions.

The main difference between Notpla and bioplastics such as PLA is that although made from natural sources, they have been modified in such a way that nature is not able to break them down on their own.