How materials are transforming the present thanks to research, industry and conscious design

During the Milan Design Week 2024 a selection of innovative solutions for product design was showcased at Materially NOW, a multifaceted exhibition that physically and symbolically focused on the study of materials and the work of companies carrying out a small but great revolution: changing the present to build the future

For over two decades, Materially has been a reference point in Italy in the research of innovative and sustainable materials for the manufacturing industry and for any design-driven application. Today, Materially is an independent boutique consulting firm headquartered in Milan that combines the needs of the manufacturing sectors with the demands of sustainability, creativity, and aesthetics, typical of Italian culture. Materially NOW was conceived to be more than a standalone exhibition.

It was a forum, an active workshop, and a networking hub. Hosted at Superstudio Più inside the Superdesign Show, the space was animated by a calendar of workshops and presentations dedicated to each material on display or used as part of the exhibition design, which was also conceived in a logic of complete circularity. Within the space, three main trends identified different areas corresponding to significant approaches in the world of materials today: Aim Net Zero, Nature in Lab, Impact by Industry.

With Aim Net Zero referring to materials and design strategies targeting the overall reduction of the environmental footprint of products, Materially NOW‘s visitors had the possibility to see and further investigate practical examples.

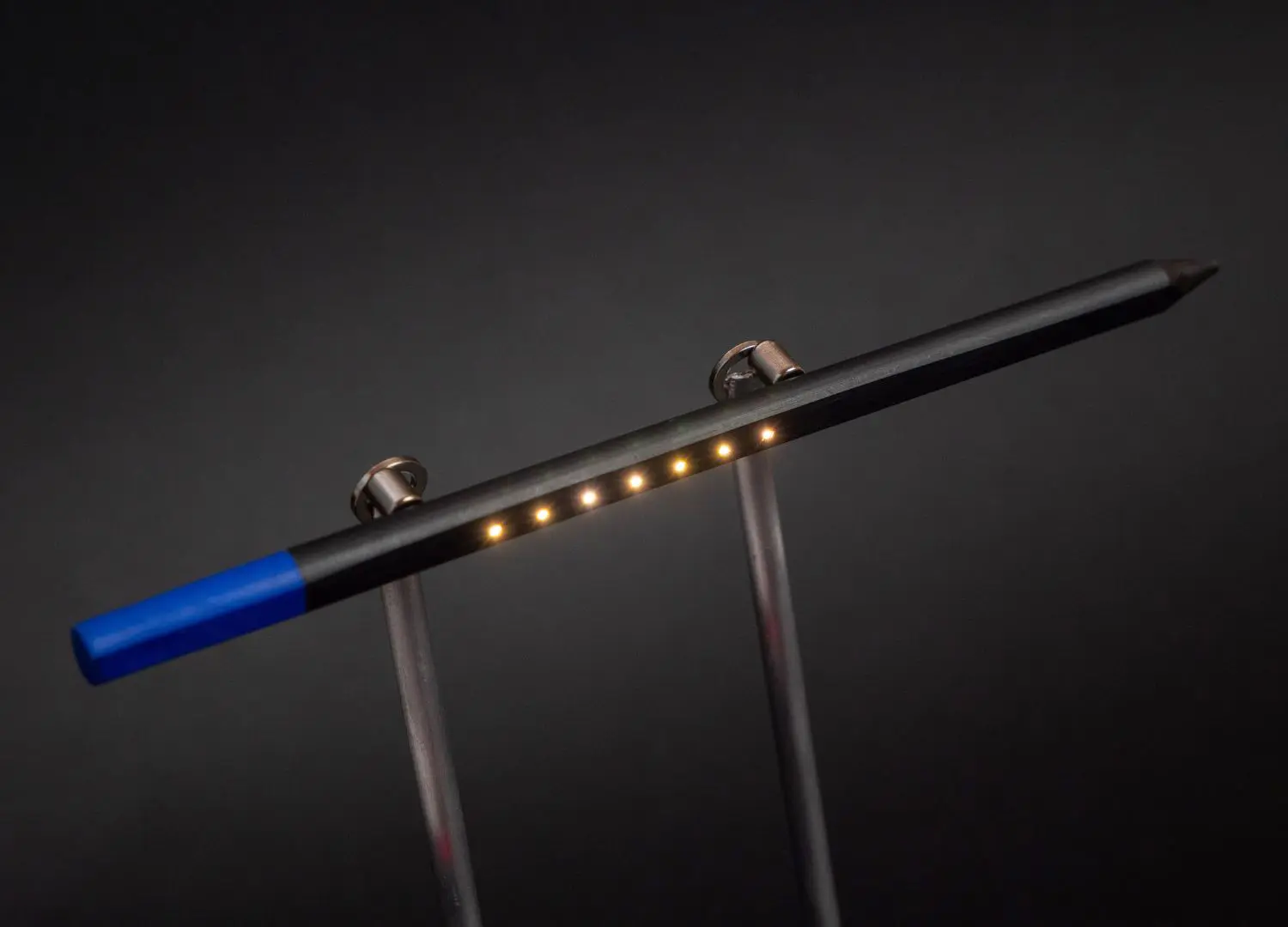

From recovering graphite from various industrial waste, Alisea demonstrated how this can be turned into a useful resource as a textile or plastic dye, suitable for application in apparel and fashion accessories, or even in lacquers or paints. Beyond innumerable applications and unpredictable combinations with materials such as wood, concrete, metal, acetate, and paper, some samples of lamps exploiting the conductive potential of recycled graphite were showcased.

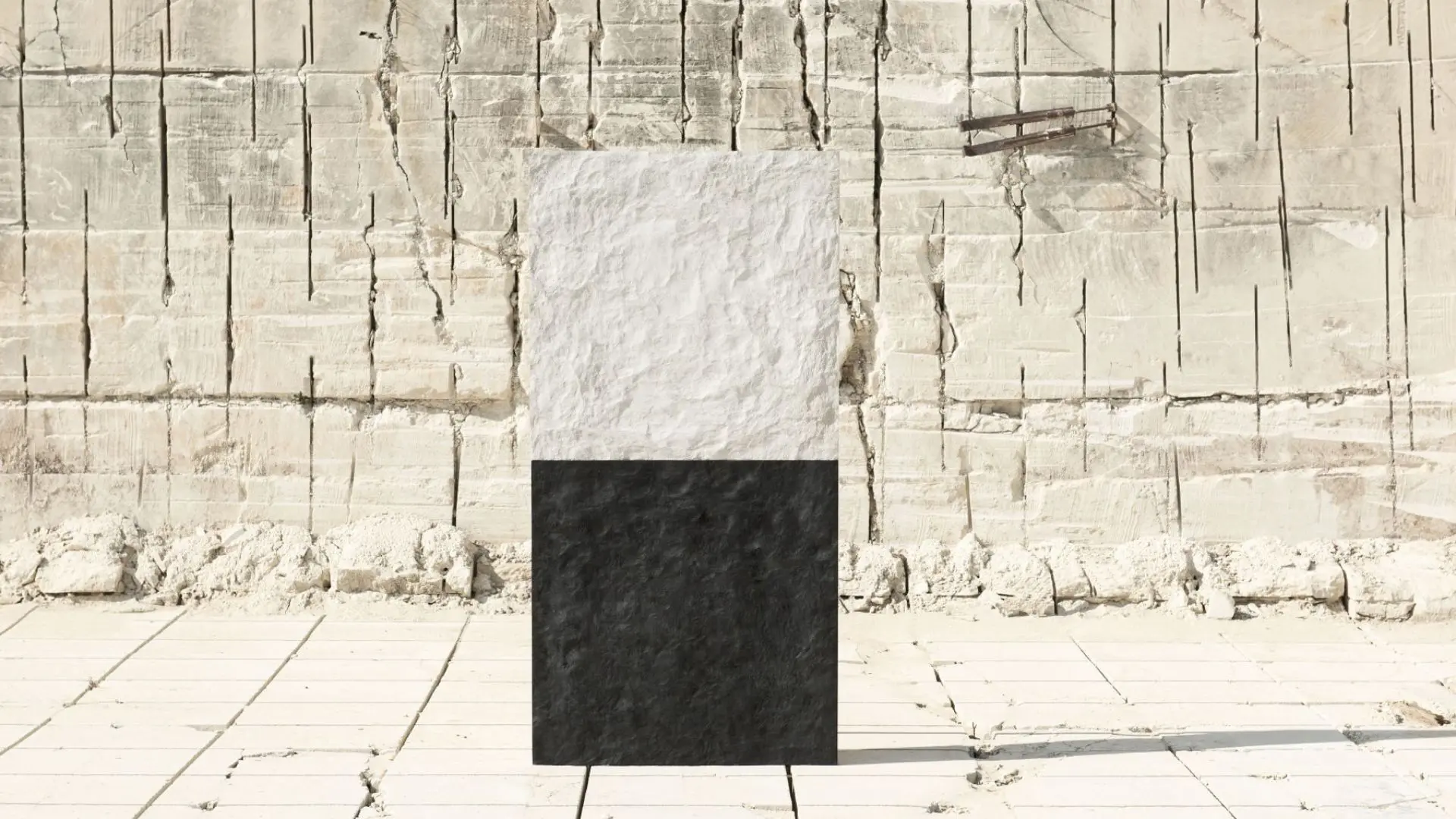

Integrating natural, secondary bio-based waste in different materials, Garzanti Specialties showcased how it is possible to recover agricultural waste such as olive piths for the production of shoes outsoles, and how, thanks to Our Carbon’s patented process, even the most humble of wastes – residues from wastewater treatment – can be transformed in a valuable carbon-negative pigment for sustainable black coloring of of plastics for injection molding or 3D printing, cement, inks and dyes, to create beautiful product, such as lamps, chairs, apparel.

On the other hand, Nature in Lab was identified as a trend describing the growing interest and commitment from both the most traditional and the newest companies in highlighting and enhancing the underestimated potential of natural materials. In this area, visitors could appreciate beautiful examples of local, traditional know-how like in the case of Mariantonia Urru’s wool projects, based on untreated and undyed wool, available exclusively in the natural chromatic scale and in its purest form; or the beauty and mechanical characteristics of Invernizzi’s 100% poplar panels, followed by Cosetex’s T.Silk collection, where silk padding and fabrics showcased the result of modern and advanced research on silk fiber and an ecodesign approach exploiting its fantastic thermal properties. Conceria Nuvolari, an Italian company that produces biodegradable, compostable and metal-free leathers, provided an exemplary tech-oriented approach to sustainability in an industry where the use of polluting heavy metals persists.

Among the newest trends in this area, Materially also brought very innovative ways of conceiving the unexpressed potential of Nature, like in the case of Mycel’s Anolea™, a premium advanced biomaterial inspired by the intricate structures of mushrooms, crafted with cutting-edge biotechnology processing, representing the ultimate alternative to leather; and the case of works from Silklab, whose researchers reverse engineer silk starting from cocoons, to obtain a silk solution that becomes the starting point for the fabrication of materials that are simultaneously “technological” (e.g., mechanically robust, micro- and nanostructured, high-performing) and “biological” (e.g., living, adaptable, bio-functional).

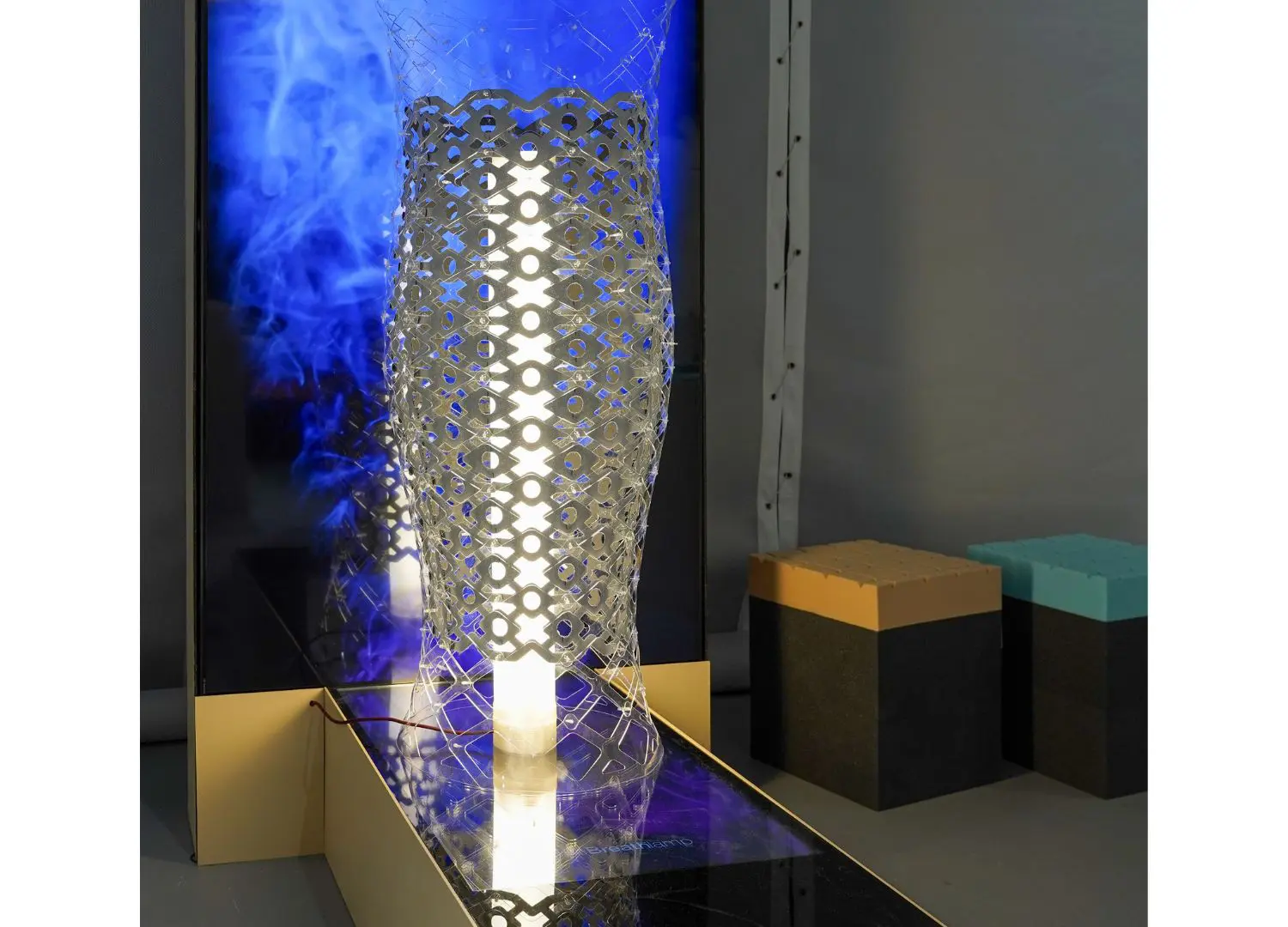

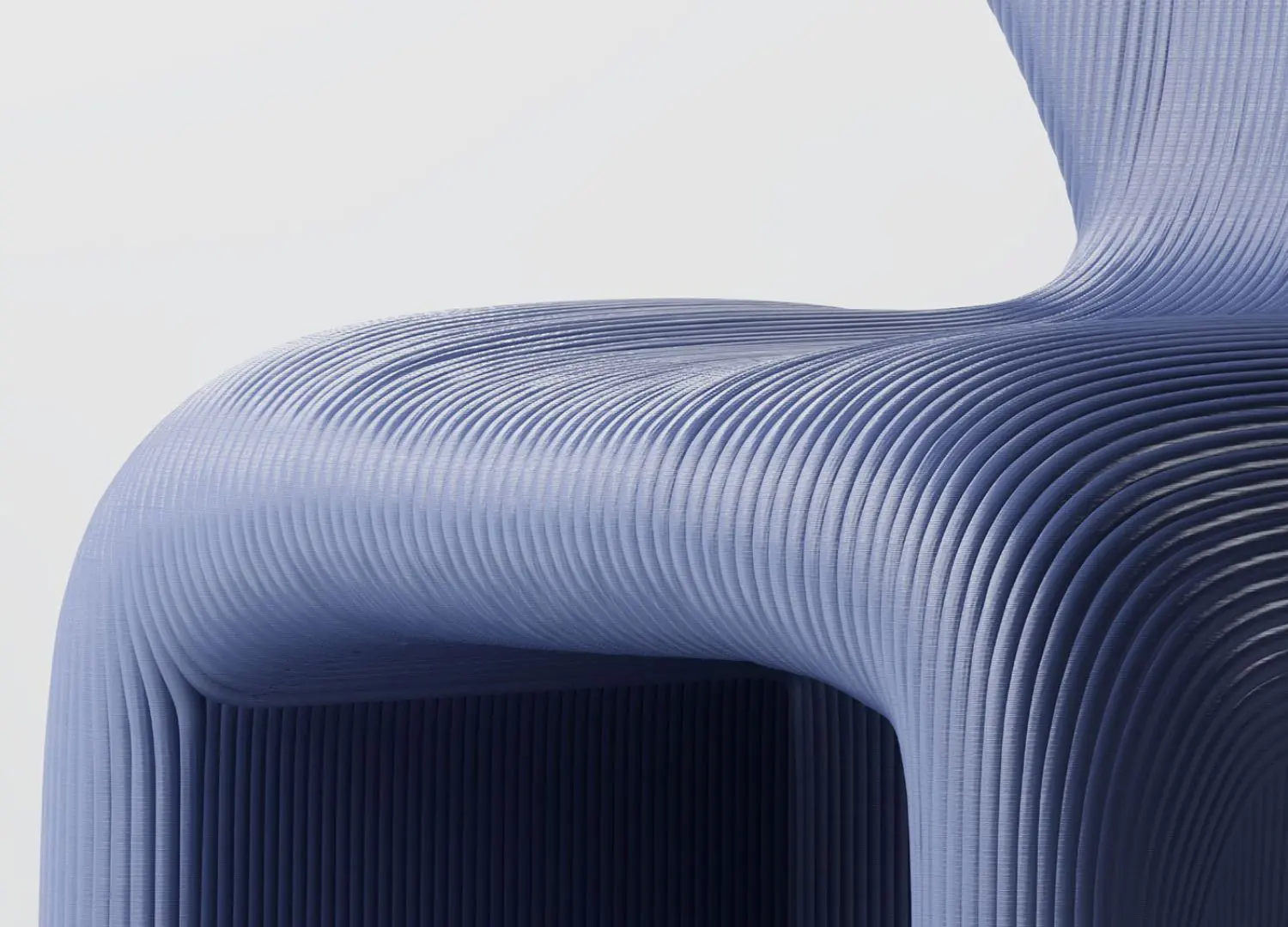

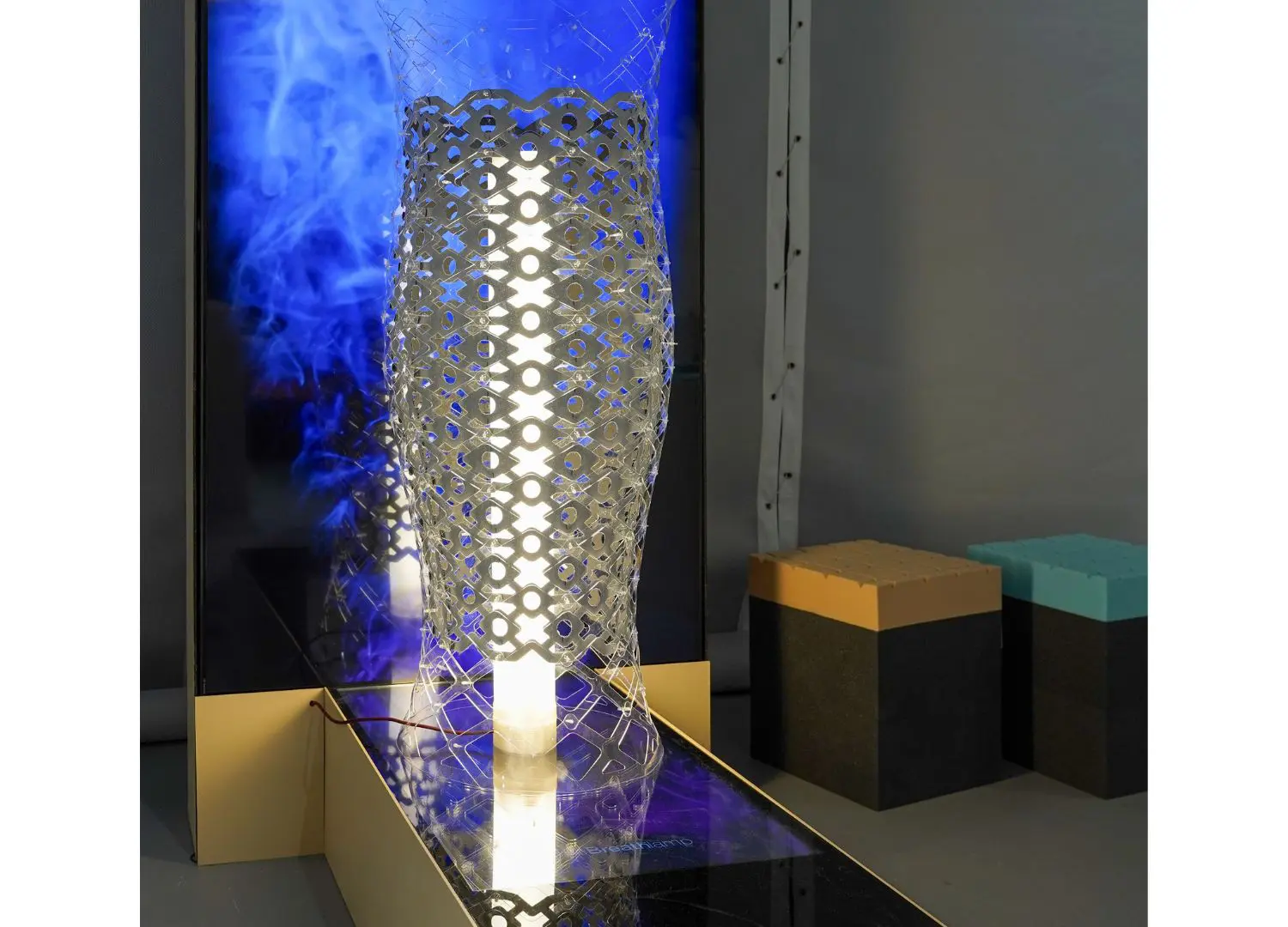

Finally, Impact by Industry focused on the processes and solutions demonstrating how technological know-how can concur to reinvent standardized common goods while promoting new cross-sector collaborations. This is the case of Anemotech’s The Breath®, a textile material that, thanks to a patented technology, absorbs harmful fine dusts from the air, showcased as an integrated component of a lamp for interiors; or Casati Flock, a historic company in the field of flocking, which applied its technology of pulverizing textile waste to a striking 3D printed chair, co-created with AI and made of a filament containing recovered denim powder.

Other solutions were provided by companies such as Sirmax, a leader in compounding from certified and traced post-consumer raw materials; a selection of low-temperature curing powder coating finishes in polyester, epoxy-polyester, epoxy, polyurethane and silicone systems by ST Powder Coatings; custom texture design and engraving possibilities with over 300,000 textures available to every manufacturing sector, thanks to Standex Engraving Mold-Tech’s know how.

The Materially NOW’s audience also had the chance to evaluate the use of various types of polyurethane foam in their bare form. This is a material undergoing a strong phase of innovation, well expressed by the manufacturing companies of the association Poliuretano è – Pelma, Orsa and Olmo and a Swiss start-up, VIRIdiVITA, using polyurethane foam as the base material to grow vertical and roof gardens.

To complete the Materially NOW installation, some further materials were used that aligned with the Aim Net Zero trend: Madreperla’s Greencast 100% recycled acrylic sheets; Plastiz’s elegant recycled plastic panels; Favini’s papers that integrated cocoa bean waste.