Papershell, when material becomes the model

Papershell doesn’t just offer a new material – it proposes a different way to think about sustainability, industry, and the role of design in shaping systemic change.

In a time when sustainability risks becoming a marketing cliché, Papershell stands out for one simple reason: it puts the material first – not just as a product, but as a philosophy, a business model, and even a form of positive activism.

The Swedish company was born from both a technical challenge and an ethical question:

Is it truly possible to replace plastic with something genuinely sustainable, scalable, and credible?

Anders Breitholtz, the founder, didn’t want to adapt to the limits of what already existed. He wanted to invent. Instead of tweaking conventional materials or settling for half-solutions, he created something new and with it, a company rooted in the belief that materials should tell the truth. What we make must reflect what we believe in.

Gallery

Open full width

Open full width

nurholz – Hightlights:

A background rooted in design, not finance

Anders is not a conventional entrepreneur. He is an industrial designer whose career has always been guided by a deep fascination with materials and how they behave. Early on, he realized that without understanding materials intimately, design risked becoming superficial. “It was like being a musician without knowing harmony,” he told me in conversation, recalling the frustration that drove him to move to the United States after graduation. There, he immersed himself in the science of materials: how they age, respond, transform and how they can be reimagined.

Returning to Sweden, he launched a material library focused on helping companies make better material choices. His practice was powered by a vast material library, serving clients eager to innovate more responsibly. But soon, he noticed a troubling paradox: sustainability was becoming a selling point, but most solutions were superficial. “I saw a lot of attempts to replace plastic… with more plastic,” he said.

That contradiction, between intention and execution, became the spark for what would eventually grow into a new venture.

The birth of a material and a company

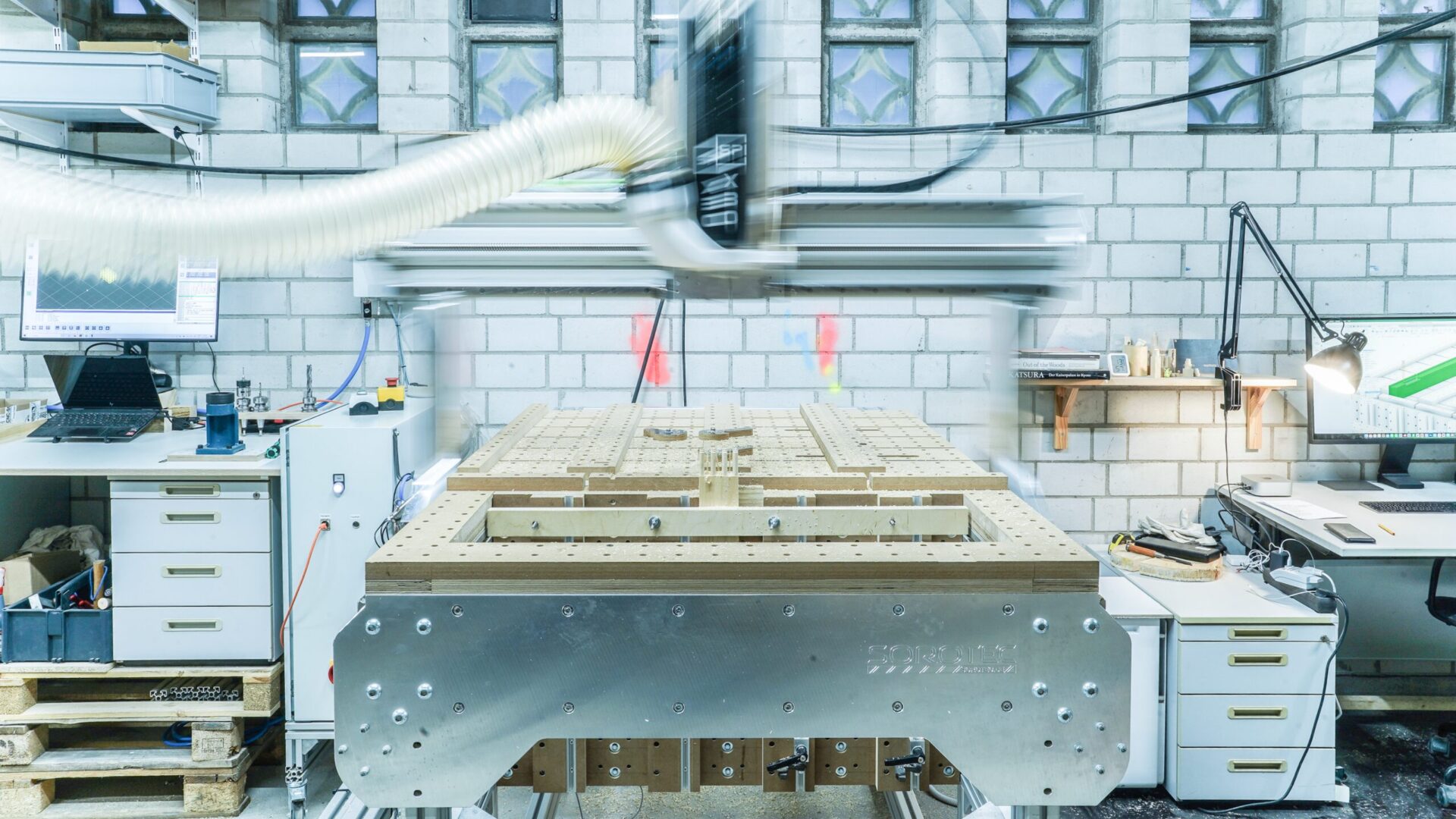

The turning point came when Anders developed a new composite made from stacked layers of kraft paper, bonded with a bio-based resin, and pressed into shape through a fully automated process.

The result was Papershell: strong, moldable, lightweight, recyclable and carbon-negative. A material capable of outperforming many conventional plastics in structural applications, all without petroleum chemistry. At first, Anders considered licensing the material or partnering with an established manufacturer. But those closest to him – engineers, designers, friends – convinced him otherwise. They believed only he could lead this vision with the authenticity it deserved.

In 2021, Papershell was founded, with a small team and a bold ambition: to prove that material innovation could be both ethical and industrial.

Demonstration by design

Launching a material is far more complex than launching a product. It’s abstract. It requires imagination and trust. So instead of relying on technical specs, Anders turned to design to tell the story. He began recreating iconic furniture pieces using Papershell, familiar shapes, reinterpreted through a new material lens. The most notable outcome was a collaboration with Arper, one of Italy’s most respected furniture companies, which reissued its iconic Catifa chair using Papershell. The result – Catifa Carta – was more than an experiment. It was proof that a product rooted in petroleum could be reborn in a completely new material, without compromise in form or function (We have talked about Catifa Carta in this article).

Engineering trust, not just performance

Behind the scenes, the technical demands were significant. Papershell had to meet industry standards, perform consistently under stress, pass fire-resistance tests, and adapt to automated production.

But Anders and his team understood that technical validation alone wasn’t enough. If they wanted to replace plastic, they had to earn trust – not just from engineers, but from designers, clients, and the public. That trust would be built through transparency. Every prototype, test, and use case became part of an ever-growing archive – visual, measurable, replicable. The company’s communication reflects the same values as the material itself: precise, structured, and honest.

A model shaped like the material

The structure of the company mirrors the properties of its product. Papershell is layered – flexible yet robust, engineered yet organic. It doesn’t aspire to become a lifestyle brand or a furniture manufacturer.

Its goal is to enable: to be a material partner that helps industries transition toward better production models.

From furniture to mobility, from interiors to construction, the same principle applies: adapt to the needs of each sector, without ever compromising the core values. For Anders, material is never neutral. It’s a language. And Papershell speaks with clarity.

Designing impact from the ground up

Papershell isn’t just offering a better alternative. It’s proposing a new framework for how materials, business, and design intersect. Here, innovation is grounded in ethics. Product development begins with values. Communication is treated as an extension of the product itself. And design becomes a tool for translation – from complexity to clarity, from chemistry to culture. At a time when sustainability often feels like surface talk, Papershell reminds us that true change comes from systems, not slogans. Their approach is a call to go deeper, to build better from the inside out.

If you enjoyed this article, we’ve published more stories about Design Models and how they’re successfully applied in the industry with sustainability in mind. Take a look Kooij, Mater or Matrec, three case studies that explore different approaches to sustainable innovation.