Philips MyCreation lights up the future of 3D printing

Bart Maeyens, Head of Philips Mycreation’s 3D printing business unit, explains how the brand is democratising 3D printing and pushing the boundaries of sustainable lighting design.

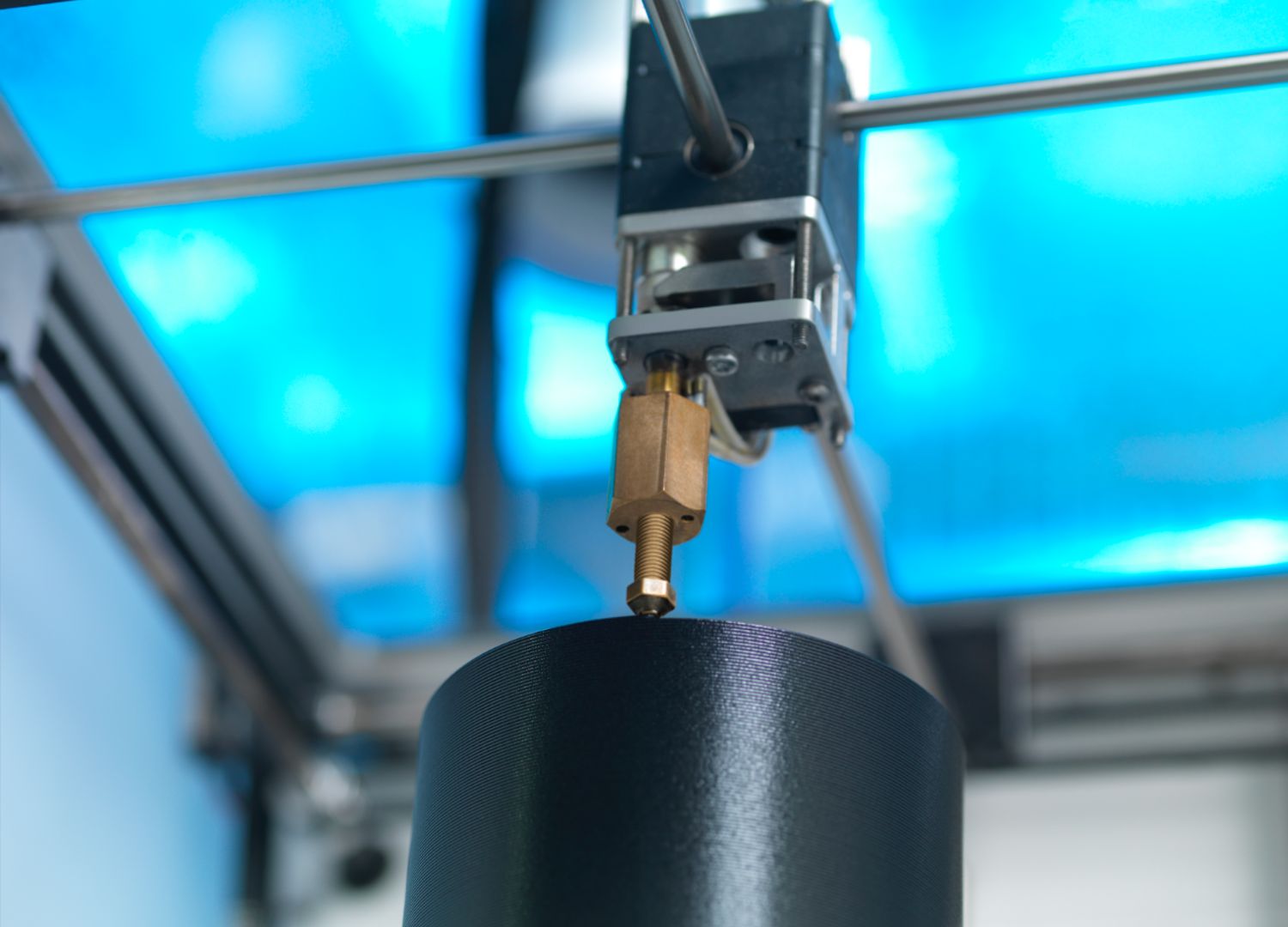

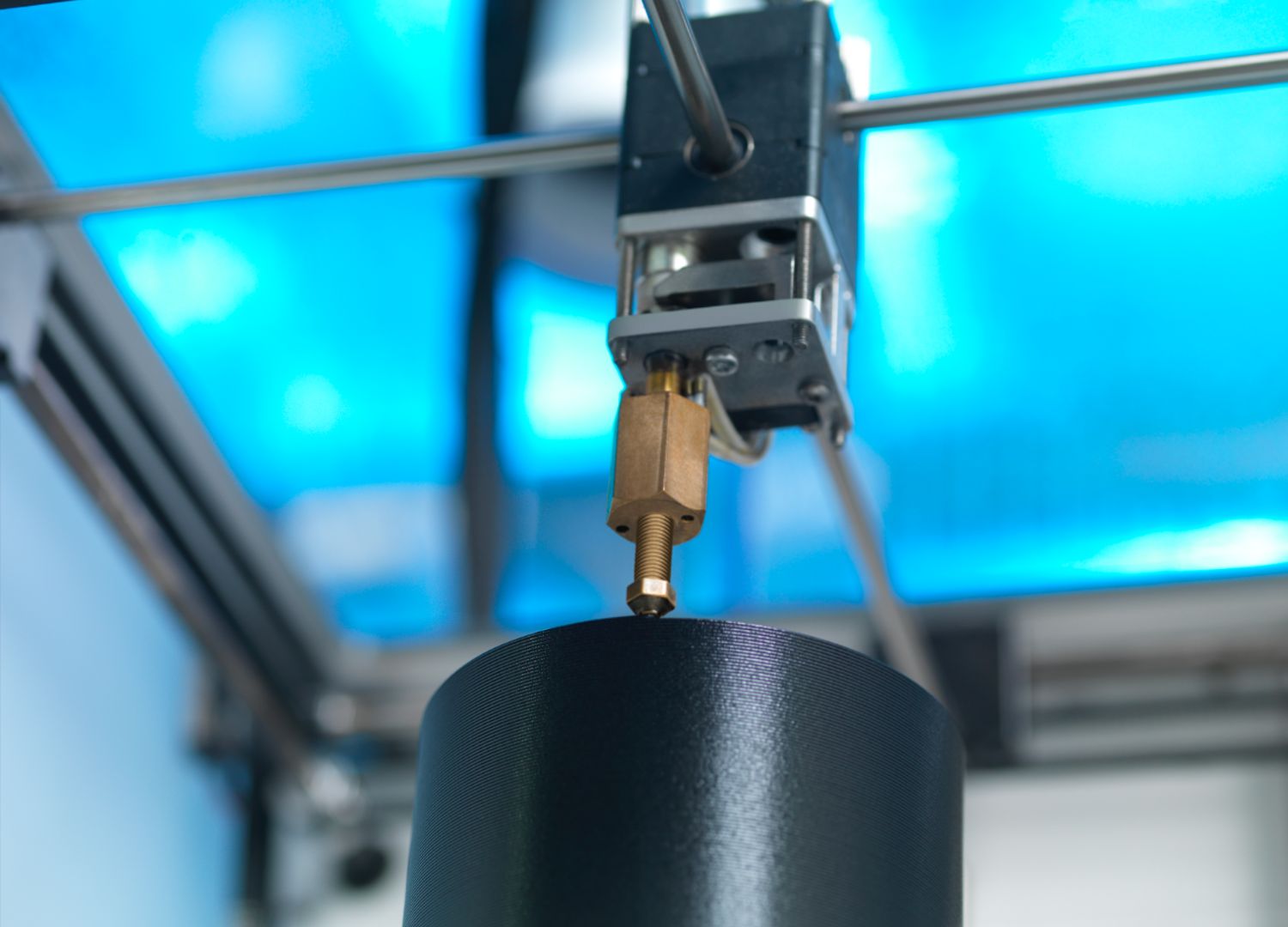

Armed with the latest in 3D printing technology, Philips MyCreation is on a mission to transform the lighting industry one custom luminaire at a time. This venture is imbued with the knowledge and expertise of its parent company, Signify, the world leader in lighting, which has been navigating the complexities of 3D printing since it was founded in 2016.

One of their goals is to democratise the technology behind it, making 3D printing more accessible to professionals and consumers alike. That’s why Signify launched the Philips MyCreation brand, which offers users an online platform and an intuitive interface to customise and 3D print unique lighting fixtures tailored to their preferences.

Since then, the platform has gone from strength to strength, underscoring the significance of agile production methods in meeting customer demands with speed and efficiency.

Through collaborations with research institutions and startups, Philips MyCreation continuously refines its processes, pushing the boundaries of sustainable design and production. Meanwhile, Signify constantly looks ahead, setting ambitious goals for the future with a focus on climate action and reducing landfills.

To delve a little deeper into their groundbreaking venture, Designwanted spoke to Bart Maeyens, Head of the 3D printing business unit at Signify.

One barrier to the widespread adoption of 3D printing is the perception of complexity and accessibility. How does Signify address these challenges to encourage more people to embrace 3D printing technology?

“This is exactly why we have made it our objective to innovate where possible to make mass produced usage of 3D printing a reality, ” says Maeyens. “By making 3D printing within professional and consumer lighting a mass-produced, global setup, we can ensure there is an adoption across all geographies and customer bases.”

“One of the main ways we minimise the complexities of 3D printing is by communicating the customer benefits more than the intricacies of the technology itself. Our main pillars are creativity and sustainability, and with that, we serve the benefits of 3D printing, more so than the technology itself.”

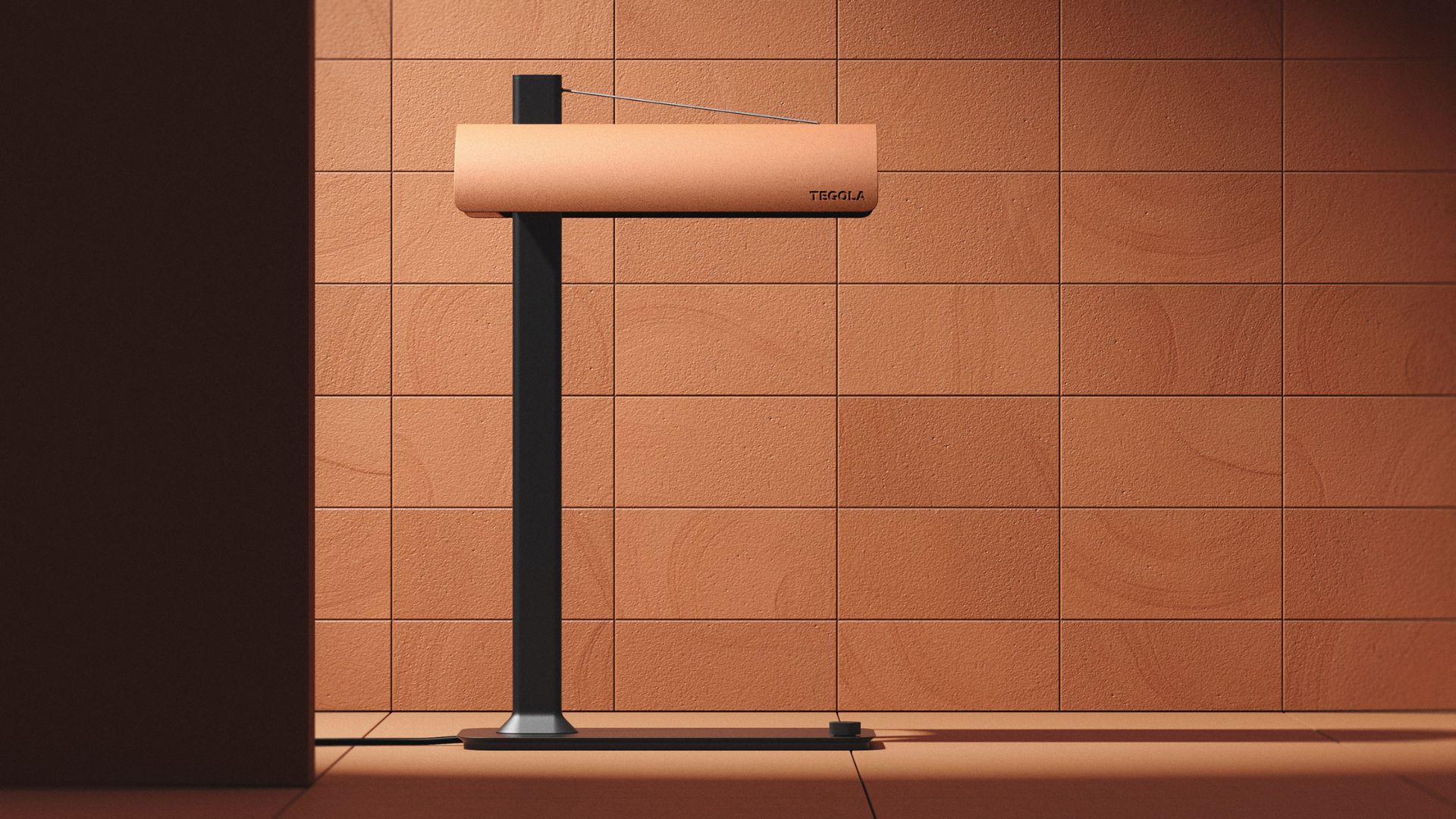

Originally launched in 2019, Philips MyCreation does just that, welcoming users with an easy-to-use web interface that lets them select from a range of shapes, textures, colours, ceiling caps, cables, and bulbs. Within minutes, you can design your own lighting fixture 3D printed on-demand and have it delivered to your home. Alternatively, you can enquire for larger-scale orders, making the most of the brand’s printing hubs across Europe.

“This will unlock the extraordinary potential of light as you can unleash your creativity in a mass produced yet customized manner,” says Maeyens. “Our online configurator gives users more than 190 design options mearly in color and texture combined.”

What this means for clients of Philips MyCreation is the possibility to constantly upgrade and update their lighting technology. As you close the loop and produce locally, the impact of updating is minimised over time and offset by the option to innovate with upgrades instead.

Could you highlight some notable successes that have emerged from Philips MyCreation? What specific challenges has Signify encountered, and how have these obstacles been addressed?

“Major success has been achieved in large retail spaces with our customers across the globe: Carrefour, Jumbo, Aldi, Costco, Total Wines, Bunnings, to name a few”, says Maeyens. “Across the board, the main challenge was finding a way to ensure a custom created luminaire could be made in a period that conventional production methods would never allow.”

Thankfully, Philips MyCreation has mastered a production process that ensures short lead times, in part because it operates on an on-demand basis. From initial discussion to prototype, it is possible to design, personalise and produce a sustainable product within 3 months.

This process also eliminates the need for stockpiling finished products, thereby mitigating the risk of unsold inventory, minimising inefficient capital, energy, and material usage. Maeyens calls it an “agile approach”, which not only streamlines operations, but it also liberates the company from the burden of maintaining warehouse facilities.

“Those are tremendous successes from the product and operations viewpoint,” he says. “Not to mention the strides we’ve made when it comes to using post-consumer recycled materials, bio-circular or post-industrial recycled materials.”

This brings us to the second biggest challenge—ensuring that these proposed alternatives to manufacturing methods and materials can be deployed on a global scale within a large volume roll-out. To achieve this, Philips MyCreation has focused on leveraging 3D printing in small regional printing hubs across Europe. Furthermore, Philips MyCreation’s production methods focus on highly automated systems that are digitally integrated end-to-end, leveraging advanced software to meticulously control the entire supply chain.

“This in turn has allowed us to achieve sustainable targets that no one has been able to in the lighting industry,” he explains.

“On a global scale, Signify has already outperformed everyone with its “brighter lives and better world program.” We add the cherry on the proverbial cake with world class sustainability towards a truly circular future, best in class EPDs, Declare and ISCC certification.”

Launched in 2016, our “Brighter Lives, Better World” is Signify’s sustainability program, which sets ambitious targets focusing on the areas where it can be most influential: “With our Brighter Lives, Better World 2025 program, we are taking specific, measurable actions to double our positive impact on the environment and society, using the United Nations Sustainable Development Goals as our strategic compass,” explains Maeyens.

Signify has been reducing its carbon emissions and since 2020 relies solely on 100% renewable electricity. In addition to these operational milestones, the company sets itself apart with a comprehensive approach to design and production.

As a result, it’s no surprise that sustainability stands as a foundational principle and core value for Philips MyCreation. Embracing a circular economy, the company is revolutionising material flows, transitioning from virgin to recycled and bio-circular sources, from finite to renewable resources, and from linear to closed-loop processes. The entirety of its supply chain is geared towards socially, ecologically, and economically sustainable production, a commitment underscored by its ISCC Plus certification.

“We are equipped to furnish the requisite environmental data essential for numerous environmental or green labels and certificates. This is achieved through conducting a Life Cycle Assessment (LCA) for each product series and generating an Environmental Product Declaration (EPD) to effectively communicate the findings.”

“That can be added to our sustainability achievements, which include a 74% reduction in CO2 and 0 waste in production, waste material or bio-circular material usage.”

That said, what are your insights on the potential impact of 3D printing on traditional manufacturing methods, and how is Philips MyCreation aligning with these shifts in the industry landscape?

“It’s about saving this wonderful planet,” says Maeyens. “By cutting the usage of material to the bare minimum and becoming a circular economy, we can eliminate the need for Carbon emissions from transport as we only manufacture what we need, where we need it.”

“This allows for the lowest energy consumption possible, as you can base the factory where you need it and ensure that it functions in the most energy efficient manner by using natural and environmentally friendly energy resources, such as wind and solar power.”

How does Signify actively engage with research institutions, startups, and other industry players to foster collaborative innovation within the realm of bespoke 3D printing, particularly with a focus on sustainable practices?

“We collaborate in several areas of the business including printer innovation,” Maeyens explains. “We work with all parties to create a unique industrial setup that has hundreds of printers around the globe, printing day in and day out.”

“In doing so, we have been able to deliver nearly 2 million luminaires to date, a feat that has required continuous innovation in hardware, software, and general operation digitization.”

Philips MyCreation is part of various consortia around the world, including regulatory bodies to improve the overall frame of lighting, such as Lighting Europe, as well as more specific and local bodies groups to promote networking and the sharing of knowledge, like Sirris and Brainport.

As well as its own internal research, Philips MyCreation co-develops materials with partners, and laboratories before deploying them into their printer farm to eventually become tangible lighting products for its clients.

Looking ahead to the future, what projects or initiatives do you have in the pipeline between Signify and Philips MyCreation, particularly those aimed at pushing the boundaries of 3D printing technology and sustainable design?

“Furthermore, we’re passionate about expanding our customers’ choices for design and personalization,” says Maeyens. “Through enhancements in user interface and user experience online, particularly within our configurators, we’re empowering individuals to express their unique tastes and preferences.”

“We’re dedicated to pushing the boundaries of light experience worldwide through our advanced product roadmaps. Our relentless pursuit of innovation not only enhances efficiency and quality but also drives us towards greater sustainability and circularity. We’re also constantly refining our printer platforms and materials to ensure that our processes evolve from sustainable to truly circular.”

In line with its commitment to innovation and customer satisfaction, Philips MyCreation is introducing new printers that elevate the complexity of its product architecture: “This expansion broadens our offerings and extends our applications into diverse sectors, ranging from retail and office environments to hospitality settings.”

Getting ahead of technology works in tandem with their sustainability efforts as Signify and Philips MyCreation continue to set ambitious goals with a commitment to further elevating their environmental impact.

By 2025, Signify aims to increase climate action revenues to 72% and has committed to achieving zero waste to landfill for all of its manufacturing sites. These are future ambitions that can be explored further in the brand’s Sustainability White Paper, which offers a deeper understanding of how Philips MyCreation’s innovative lighting solutions can help users achieve their own environmental goals, save costs, and create a positive impact.

“With our sights set on 2025 and beyond, we reaffirm our commitment to sustainable innovation, driving meaningful change now and in the future.”