A chat with Standard Equipment: how constraints fuel creativity

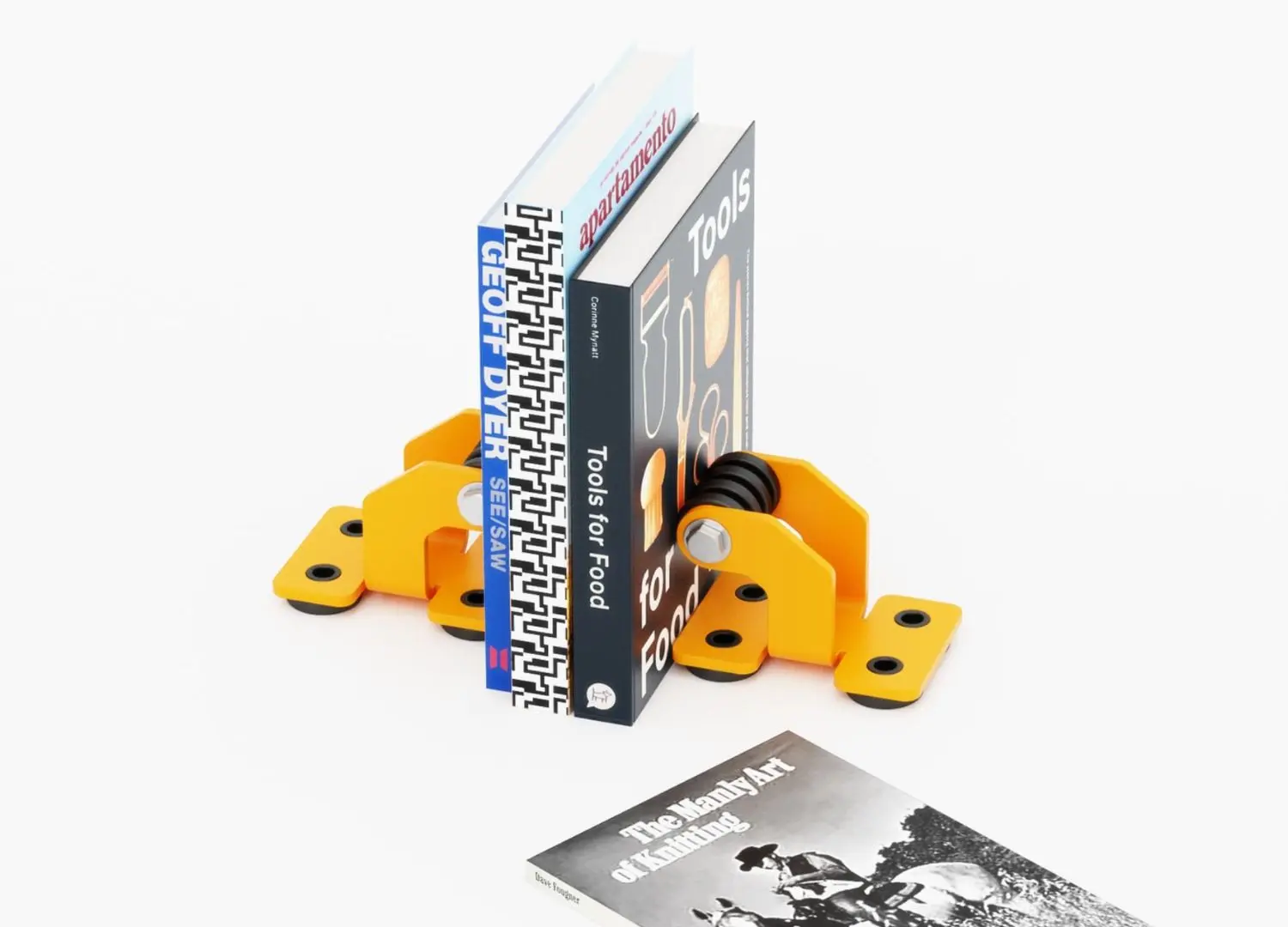

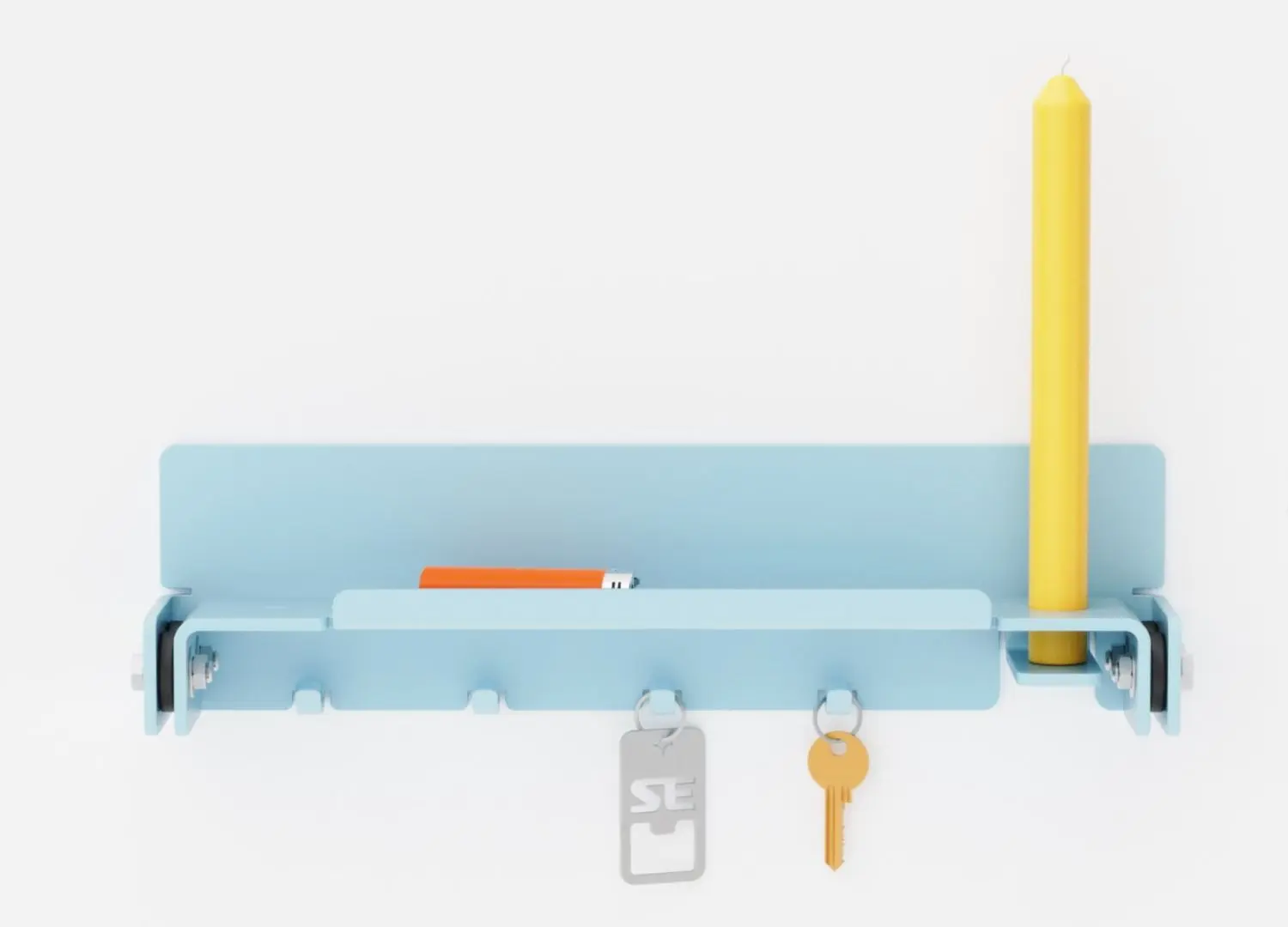

The Canadian design company is not reinventing the wheel but perhaps rethinking it, imagining a new system of what household objects and furniture can look and feel like.

In a Toronto studio where industrial precision meets postmodern playfulness, Josh Gadomski is rewriting the rules of everyday design. His company, Standard Equipment, is engineering a new philosophy of the mundane, where common objects become magnetic and start demanding a second look.

In this conversation, Josh unpacks the ideas behind Standard Equipment’s philosophy, exploring how constraints fuel his creativity and develop products for non-standard living. He traces the evolution of his design thinking, beginning from his first college projects, and explores his long-lasting love for sheet metal fabrication. Looking forward, he discusses his future ambitions for the brand, trying to answer the question: how do you scale a system without sacrificing its soul?

Gallery

Open full width

Open full width

You describe Standard Equipment’s products as “Tools for Non-Standard Living.” Can you unpack this paradox of using standardised components for non-standard ways of living?

Josh Gadomski:

“Tools for Non-Standard Living” should spark that moment of curiosity: “What is this? Oh… wow, I’ve never seen it done like that”. The slogan isn’t just a play on words; it genuinely describes how we approach design. We’re definitely not reinventing the wheel when it comes to home objects and furniture, but we like to think that we’re rethinking how the wheel looks, feels, and how the user interacts with it. We design objects that already exist and that everyone has an opinion about. From there, we apply our design formula: break the object down and rebuild it the way we think it should exist.

We take standard, often mundane items and twist them. A lot of our focus is on asking, how do we take something ordinary and give it a new presence?

Take our incense holder. At first glance, you might not even realize what it is. Then someone places an incense stick into it, lights it, and you watch as the ash falls perfectly into the C-channel, keeping your table clean. It’s a simple object, executed in a way you didn’t expect. Standard items, done in non-standard ways.

What drew you to working primarily with sheet metal fabrication?

Josh Gadomski:

Everyone has a starting point. Ours goes back to my second year of college. I had a professor, Odin Cappello, who gave us the second year chair project, where we were challenged to design a chair using two assigned materials. My team got sheet metal and plywood. At the time, I remember thinking, “how the hell am I supposed to make sheet metal comfortable?” and, without realizing it, that challenge planted the seed for what is now Standard Equipment.

Fast forward ten years and sheet metal still hadn’t left my mind. One night, lying in bed, I started designing a stool in my head. It was 5mm aluminum, stainless-steel hardware, and silicone spacers to buffer the metal components. I got out of bed, modeled it in CAD, rendered it in KeyShot, and that was my first design for SE. That became the formula, which is still the heart of all of our designs: sheet metal, silicone spacers, M8 stainless steel hardware. Simple, yet can be designed in so many different ways.

Can you walk us through how you developed the company’s “unified system” of products?

Josh Gadomski:

When SE first started, I didn’t have many contacts or much manufacturing knowledge. What I did know was I could get sheet metal laser cut, bent, and powder-coated and hardware was easy to source. That was the foundation. The only thing was that, metal-on-metal contact felt wrong to me, almost like nails on a chalkboard. So, I designed the SE Spacer out of silicone to give the perfect amount of breathing room between the sheets. It solved a functional problem while giving the pieces a distinct visual identity.

Ironically, the spacer went against my initial philosophy of only using easily accessible processes and we had to create a mold, which meant we had to commit to producing them in large quantities. That forced me to think strategically: if we’re making thousands of these, how many ways can we use them? First, the stool, then a table, a chair, an incense holder, a candle holder and shelving. That’s when the unified system really took shape. Now, whenever we introduce a new component, like the silicone gasket for our mugs, we immediately ask: where else can this live? That same gasket now shows up in ashtrays and coaster sets.

The unified system simplifies inventory and extends the use of every component. Instead of constantly inventing new parts, we push existing ones further.

What are the creative constraints that come from committing to a modular system? Does it feel limiting or liberating?

Josh Gadomski:

For me, designing without constraints is overwhelming. The modular system creates boundaries, but in a productive way, kind of like a capsule wardrobe. It turns design into a challenge instead of a free-for-all. What we’ve built can be manipulated and adapted to almost any object or piece of furniture. And it creates recognition. When you see thick sheet metal, exposed M8 hardware, and spacers, you know it’s Standard Equipment (at least I hope!).

It’s almost like a creative equation: this plus this plus this equals that. We experienced this fully when we worked with a second-year design class this past year, which was a full-circle moment. We gave the class our constraints and told them they could design anything using those materials, as long as they fit on a table and made them happy. Every single student delivered something strong. After four weeks, I couldn’t even pick a winner. That experience confirmed something for me: the system doesn’t restrict creativity, it supports it.

What materials, ideas, or collaborations are you curious about for the future of Standard Equipment?

Josh Gadomski:

Lately, I’ve been thinking about how to keep the system fresh. Sheet metal will always be our base, but we’re starting to incorporate more machined and cast components. I’d love to introduce more organic forms into our designs with the incorporation of stone that can add texture and contrast to our existing materials. We love the idea of using unpolished, raw stone against the precise, controlled sheet metal. One day, I’d also like to incorporate a universal joinery system, one mass-produced component that can connect across a wide range of products. That’s still in its early stages, but it’s an exciting direction.

As for collaborations, there are a few directions that excite us. Within the furniture or object world, we would love to collaborate with some well-established brands (whether it’s clothing, automotive or furniture) to bring in new audiences and approaches. Aside from that, we’d love to go beyond homeware and start designing larger spaces. It’s always been a big goal of mine to work with fashion brands to design out-of-the-box showrooms or runway environments. I’d also love to partner with hotels and restaurants, creating bespoke pieces for their interiors or producing larger runs of our existing furniture for commercial spaces. The goal is to scale the system without losing what makes it ours.