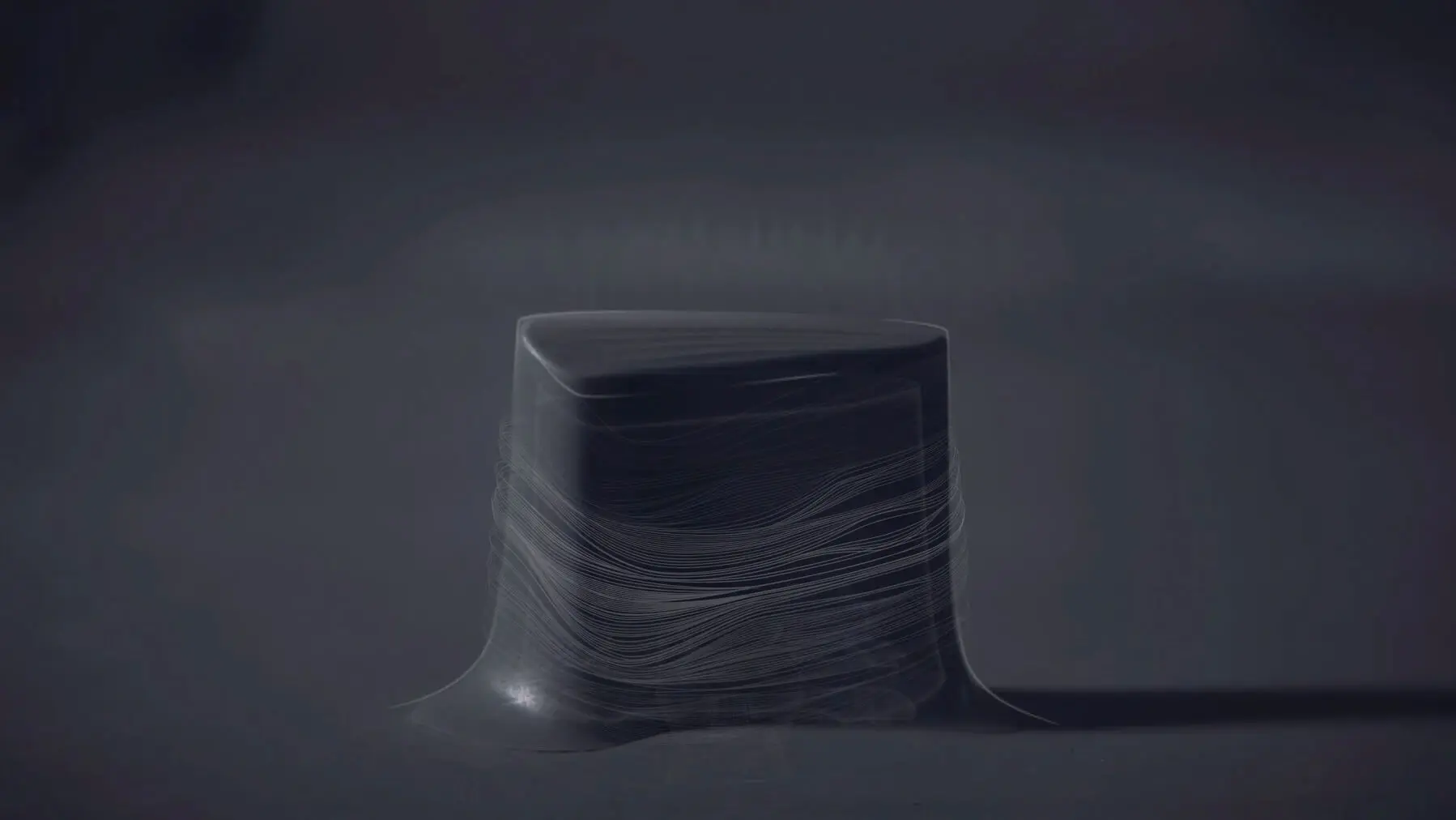

Pharmy, the autonomous navigation robot by ARBO design

ARBO design developed Pharmy, an autonomous navigation robot for hospital distribution of medicines for the 33 Robbotics brand.

The design of Pharmy is a product-service system to perform medication logistics services, bringing more efficiency, cost reduction, and safety. Its design should provide for the handling and delivery of loads in a hospital environment in a non-invasive manner, safe and with easy and uncomplicated interaction with the user, through friendly technology.

Inspired by Latin American hospitals, where health professionals are improperly allocated to carry out the transport of medicines, underutilizing their capacities and training. As a consequence, patients receive less attention or the hospital is forced to bear the cost of hiring more professionals.

Pharmy by Arbo Design is an innovator in this market, delivering efficiency, convenience, and reducing operating costs. The product also provides the flexibility to be used in other environments like industry or commerce.

It can be a single robot or several units of it, that map the floor plan of the workplace, be it in the hospital environment (composed of with a robotic base and a 5-drawer cabinet supported on this base) or factory (composed of with a robotic base and a chest supported on this base). In the case of use in hospitals for the delivery of medicines, first, Pharmy is supplied with medicines at the nursing station, each drawer in your cabinet is the individual medication compartment for a patient and its opening is only released when identified through radio frequency, ensuring safety and personal service.

After the unit is supplied with medicines, they can continue with their autonomous navigation to the delivery point, this displacement is made by the hospital corridors, at low speed and using computer vision resources to access elevators and avoid obstacles like objects and people. Upon arriving at the delivery point, the nurse can unlock the drawers and access the medications for each patient. Robotic units have the ability to move autonomously in the indoor environment and have synchronized flow with similar units that are working in the same environment, being able to work in collaboration.

The biggest challenge when building robotic units for autonomous cargo transportation in closed places, within the hospital and factory context, was to promote the efficient management of an interdisciplinary project involving several stakeholders: designers, engineers, nurses, doctors, patients, and IT professionals. Thus, the project should integrate both the development of the platform, as well as the design of the robotic unit and also of the user interface system within the context of use, hospital, and factory.

In this system, the product’s design had direct challenges: to follow the different rules in force in each country regarding the hospital environment (safety, hygiene, asepsis, etc.) and allow the flexibility to accommodate and load interchangeable cabinets for other types of indoor logistics (factories and other commercial establishments) or even be self-supporting, without the need for a superior cabinet. In this case, instead of a cabinet for transporting medicines, the platform receives a specific chest for this use. Thus, it is possible to optimize manufacturing time and costs.