From textile waste to acoustic panels—How BAUX creates sound insulation

Industrial design studio Form Us With Love, and their venture BAUX takes textile offcuts and gives them a second life as a commercial acoustic solution.

“Designing the sustainable acoustic building materials for tomorrow means producing environmentally friendly materials today,” explains Fredrik Franzon, head of product and founding partner at BAUX—a venture of Swedish industrial design studio Form Us With Love.

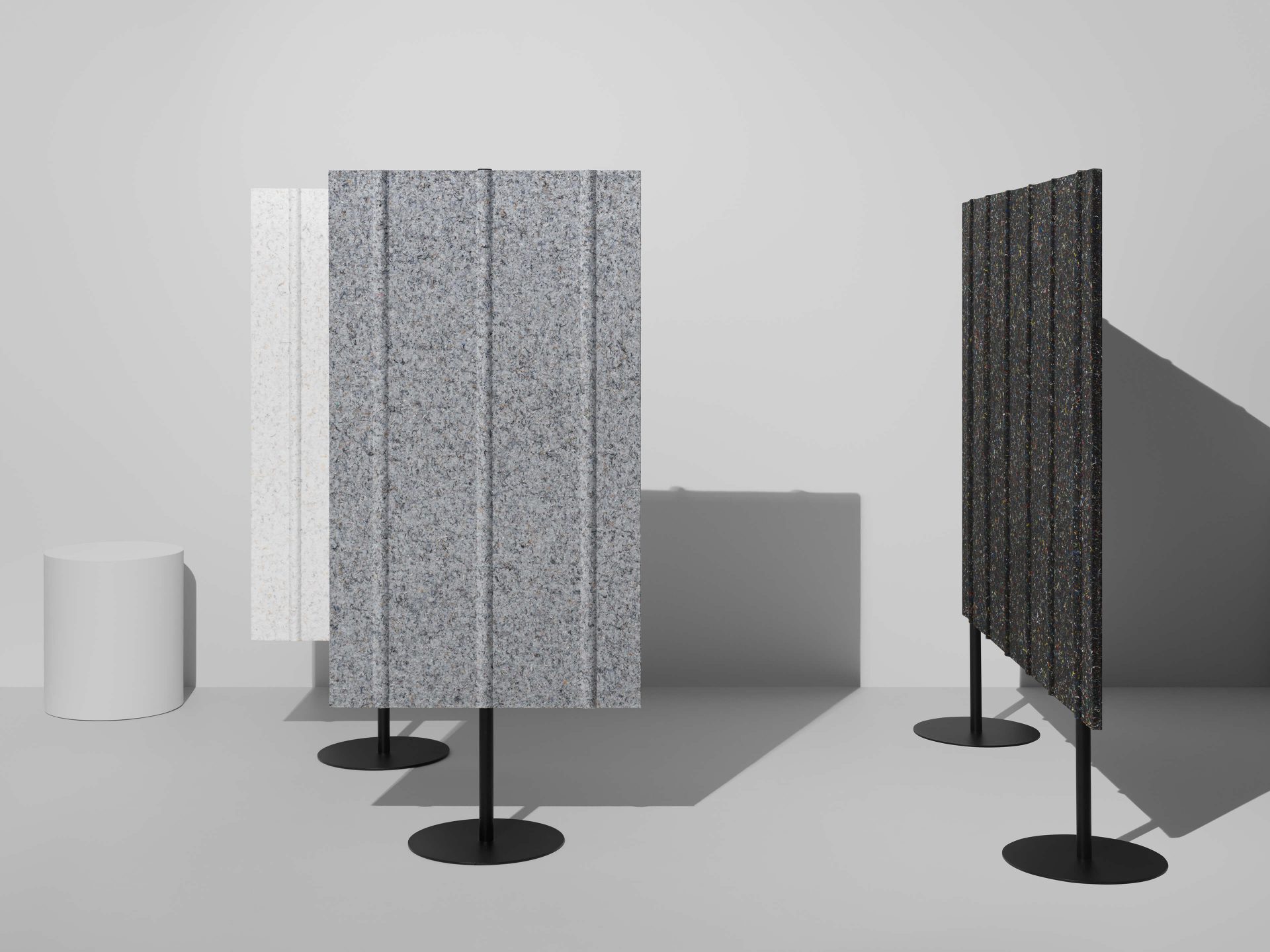

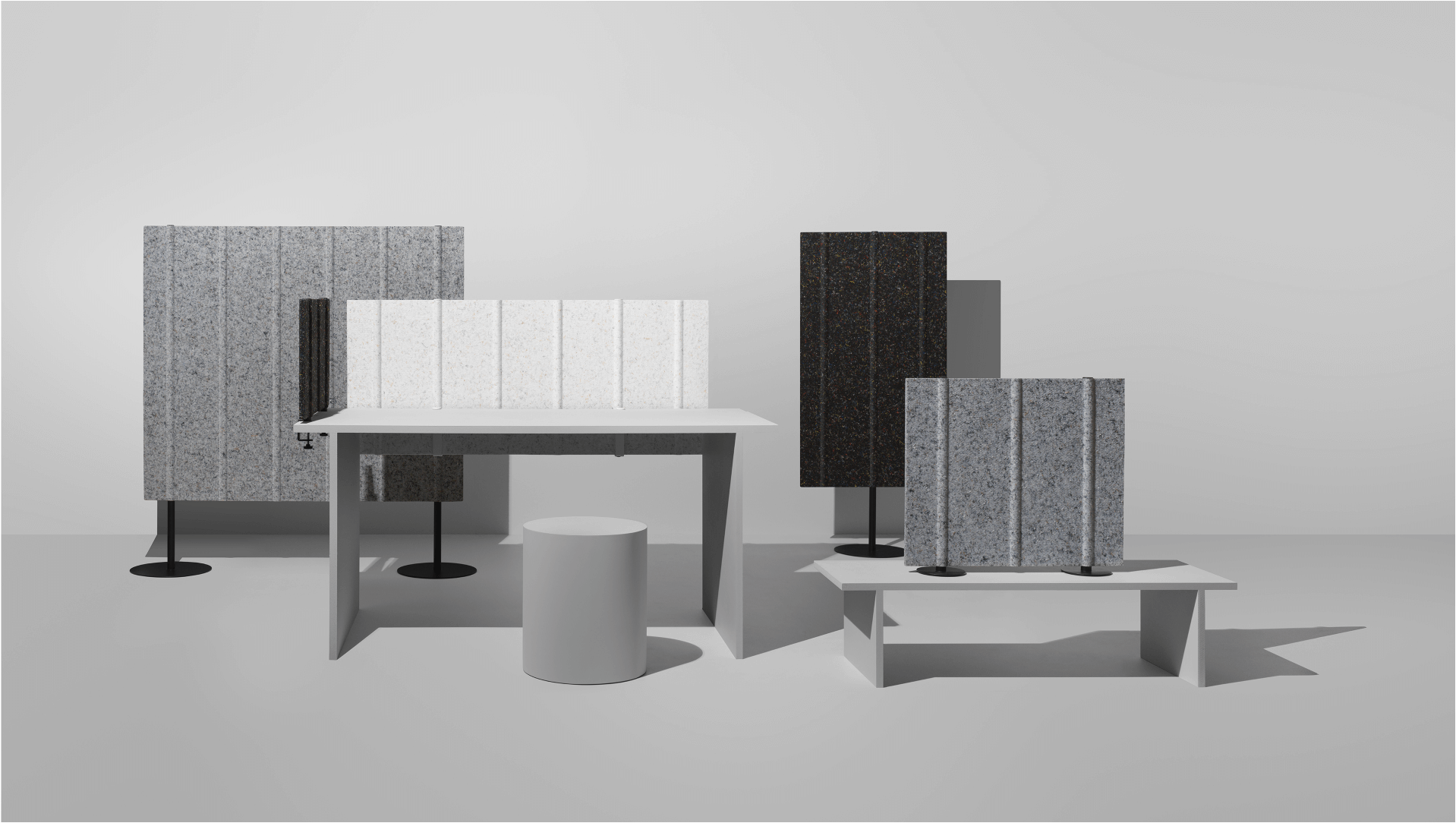

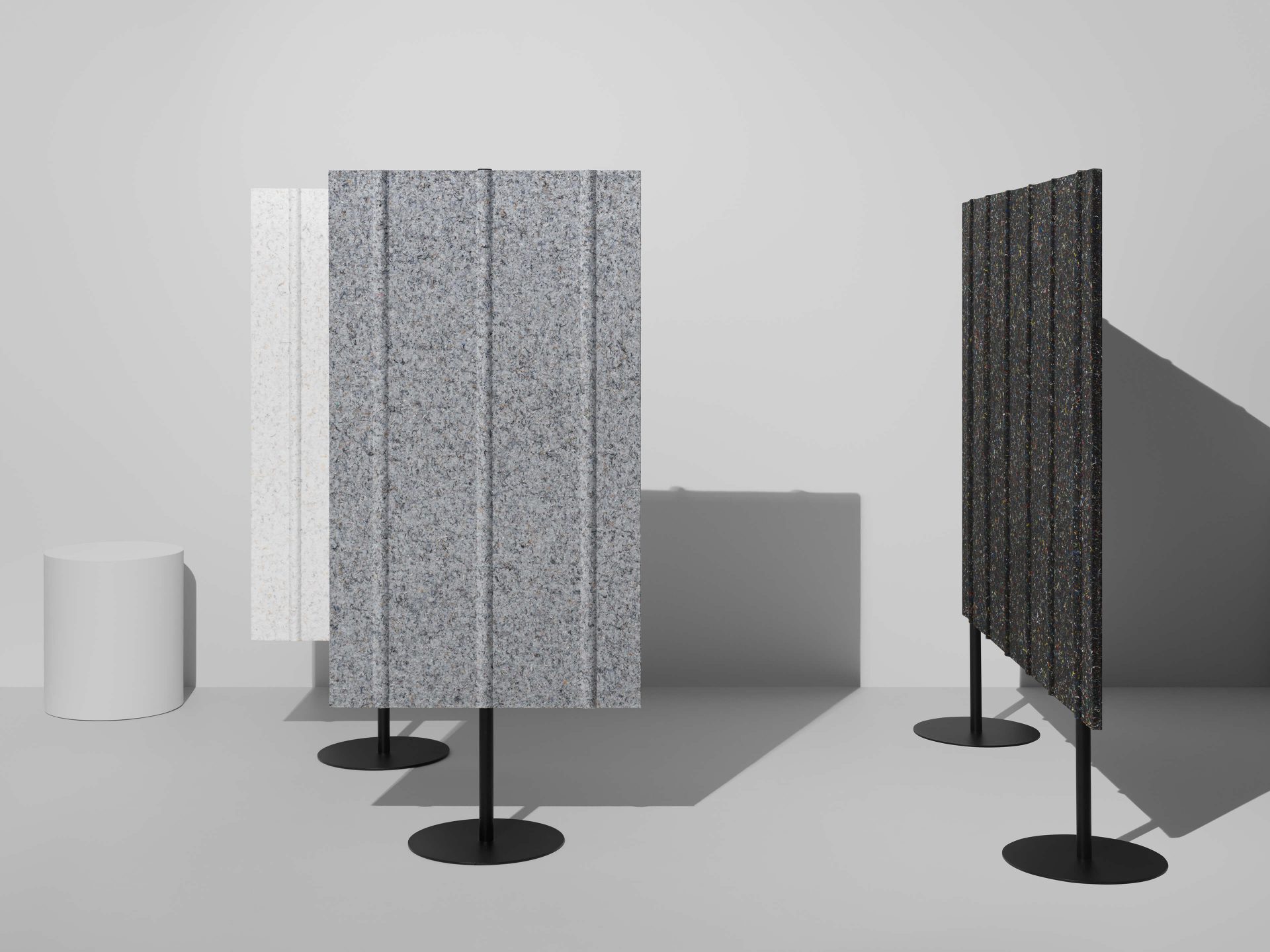

Tasked with making conventional architectural products more visually appealing, the Stockholm-based incubator has made a name for itself thanks to its vibrant collections of acoustic panels made from innovative and sustainable materials.

Gallery

Open full width

Open full width

Since 2014, it has grown to become a popular name within the architecture industry, working with brands such as Amazon and Spotify. Its first launch was Wood Wool, a sound absorbent material made from spruce wood, cement and water, which decorated a global interior solution loved by Stella McCartney as well as offices for Google and the United Nations.

Its latest launch, the Acoustic Felt, is a super stylish sound solution made from recycled polyester, sourced from 100% traceable textile offcuts. It proposes an industry-first solution to textile waste, of which 92 million tonnes are produced globally every year.

“The problem is that it’s often hard to locate the origin of recycled materials [because] the market hasn’t put enough demands on businesses yet,” says Franzon. “Felt for industrial applications has traditionally been made from a mix of synthetic material fibres [and] while it’s easy for acoustic product designers to simply select recycled materials, it’s difficult to pinpoint their origin.”

“Without control over the stream of material components, BAUX would risk sourcing from a corrupt supply,” he explains. “And contrary to our original intentions, we could wind up producing more plastic and compromising circularity.”

From threads to acoustic panels

To overcome this, BAUX worked with The Loop Factory, which sourced 100% polyester-based threads from Swedish textile manufacturer Ludvig Svensson. By working with Swedish supply chains, BAUX is able to keep its manufacturing network small and traceable instead of relying on large manufacturing plants or large processing facilities.

Once received, the offcuts are sorted by hand in various colour schemes before undergoing a process, undisclosed, that makes it possible to reuse the material whilst retaining its original quality.

At the next stage, the sourced polyester-based threads are taken from textile offcuts and combined with energy-efficient polyester fibres that give the material its structure. This part of the process has been specifically designed to accept material offcuts of varying fibre qualities to eliminate the potential for any further residual waste.

Next, the fibres are dyed. The panels use naturally variegated colour, scaling from white, grey and black and are dyed locally in compliance with Swedish environmental legislation. This material is then pressed in a mold and cut into nine different sizes ranging from styles including desk dividers and wall panels for use in offices and educational spaces.

Fit for office spaces

The BAUX acoustic Felt range places emphasis on function. Flexible and easy to handle, each modular component has been designed as part of an efficient system that can be quickly scaled up or down. No glue or hardware is used either–highlighting that each tile has been designed with the intention to be repurposed and reused.

“The BAUX Felt range solves most issues that an office needs to address today and tomorrow, and pushes boundaries in terms of what’s business-as-usual.” “Everything connects together with a minimal number of hardware pieces which have been standardised to ensure effortless setup and less waste in production.”

“We have secured a completely traceable source from other industrial production facilities which would otherwise be discarded as waste and burnt at a power plant—that is the first step in becoming circular, which is our long-term goal.” The Acoustic Felt is just one of BAUX’s collections. In 2019, it launched the Acoustic Pulp panel, which combines 100% biodegradable and 100% organic content for high sound absorption.

The company’s desire is to innovate whilst staying committed to the principles of circularity, designing out waste, and continuing to produce new product categories that support the challenges of tomorrow’s architecture.

Who are the partners involved in the development of BAUX Acoustic Felt?

BAUX:

“The design of the product is a joint development between BAUX and the international design studio Form Us With Love. The material development was made together with The Loop Factory, a specialist in developing and realizing sustainable solutions within materials, products and technological solutions.”

Where did the idea of your Acoustic Felt come from? How did your background experience within BAUX lead you to develop this new product?

BAUX:

“When we, at BAUX, set out to create our first-ever felt product, in a market where felt is ubiquitous, our puzzle was clear: How can we offer something new, that pushes boundaries both in terms of greater levels of sustainability and features the market hasn’t seen before? Felt has great absorptive qualities, lovely shaping properties and is aesthetically warm and appealing. But if we’re going to make products at all, they need to be future proof’.

To create a felt product in alignment with BAUX values, our design team would have to address one critical issue that was holding not only BAUX but the entire acoustic industry back from creating a truly sustainable felt product.”

Can you give us more explanation on the problem you wanted to solve?

BAUX:

“The problem is that it’s often hard to locate the origin of recycled materials [because] the market hasn’t put enough demands on businesses yet. Felt for industrial applications has traditionally been made from a mix of synthetic material fibers. While it’s easy for acoustic product designers to simply select recycled materials, it’s difficult to pinpoint their origin.

Without control over the stream of material components, they risk sourcing from a corrupt supply and, contrary to original intentions, can wind up producing more plastic and compromising circularity. We ultimately decided to come out with a felt product for two reasons.

The first is that we, together with our suppliers, have secured a completely traceable source from other industrial production facilities which would otherwise be discarded as waste and burnt at a power plant. We have control over what our recycled products contain and that is the first step in becoming circular, which is our long-term goal’.”

What is the process used to make the BAUX Acoustic Felt? Can you explain it in general terms and then specify how it’s applied to the material?

BAUX:

“The product contains textile offcuts, a 100% polyester based thread that normally would have been incinerated, combined with a low melt polyester fibre that gives the material its structure. Each batch of threads is dyed locally in Sweden in a closed process that follows Swedish environmental legislation. The material is then pressed in a mold and cut into 9 versatile sizes to meet all your design needs.”

Give us a step-by-step approach to the process.

BAUX:

“Textile offcuts are collected from the factory Ludvig Svensson, a manufacturer of curtains. The offcuts are sorted by hand in various colour schemes, they are then treated in a machine and then mixed with a low melt polyester fibre and a nonwoven sheet is produced. The nonwoven sheet is then pressed in a mold to create a rigid sheet and is finally cut with a water jet into 9 different sizes”

Can you describe the different materials used for this process? Was there any innovative technique involved in its creation?

BAUX:

“The materials used are textile offcuts (40%), Oeko-Tex ® Standard 1000, Product Class IV certification, and chemicals in dyeing are approved to REACH regulation no. 1907/2006. Materials also include thermoplastic fibre (50%), CO-PET/PET, 4dn. CAS: 24938-04-3, Polyester Fibre (10%), and PET, 12/13 dn. CAS: 25038-59-9. The innovation lies in the way the textile offcuts are treated in order to make it possible to reuse the material again.”

Is the resulting material innovative in some way?

BAUX:

“100% traceable and recycled material is used in the product.”

Can you describe the resulting product?

BAUX:

“BAUX Felt range places great emphasis on function. Flexible and easy to handle, each modular component has been designed as part of an efficient system that can be quickly scaled up or down. Everything connects together with a minimal number of hardware pieces that have been standardised to ensure effortless setup and less waste in production.

The range solves most issues that an office needs to address today and tomorrow and pushes boundaries in terms of what’s business-as-usual. And, just as with all our collections, when you invest in a our own Felt system, you can be sure it’s going to last. We’re making it easy to update, replace and extend all the components so the system keeps up with your needs over a vast period of time’.”