CENTO3: hold the latest project of Achille Castiglioni’s between your fingers

A set of pencils combining graphene with 3D printing, CENTO3 is a writing tool pursuing innovation, sustainability, respect for quality and costs

Team EGO.M introduces CENTO3, the latest and unpublished project by Achille Castiglioni brought to life. The graphic inspiration that with a thread or rather a stroke, brings back both architects Castiglioni and Cavaglià from the beginnings of their creative and design careers, to nowadays: a line, a pencil, a sign.

The project reveals itself as the wish to make unique and perfect those tools that have allowed them, form the beginning, to draw, sketch, erase and propose ideas, emotions, curiosity, solutions, irony, fun and beauty.

Gallery

Open full width

Open full width

CENTO3, are the years from the birth of Achille Castiglioni (1918) to the realization and presentation to the public of the writing project of the two architects Castiglioni and Cavaglià (2021):

- 3, the fingers holding a pencil

- 3, the arcs that make the instrument trilobate-shaped

- 3, the tools designed and the types of writing

- 3, the partners in the project: Achille Castiglioni, Gianfranco Cavaglià, Team EGO.M

- 3, as three-dimensional production technique

The writing project – A liaison between our thoughts and a piece of paper

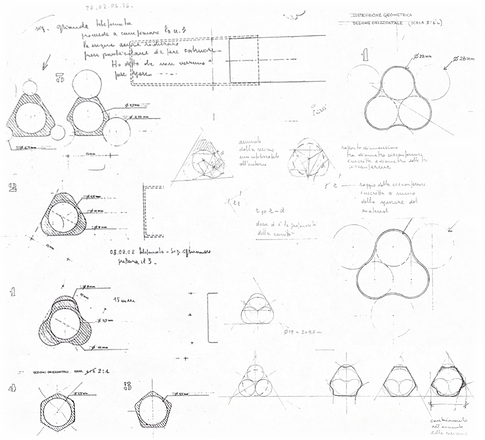

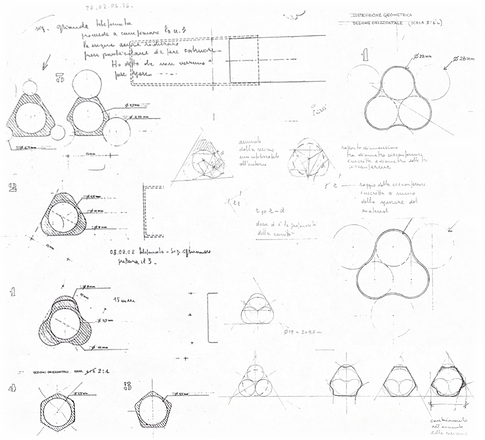

In 2001, Achille Castiglioni together with his friend and colleague Arch. Gianfranco Cavaglià deals with the significance of the ‘handgrip’. Together they design a set of pens and pencils of which some wooden prototypes were made and then kept and treasured to date in the archive of the Achille Castiglioni Foundation. Their purpose was to enhance and recall the attention to the importance of a pencil as an ordinary daily instrument and as a means of expressing ideas and thoughts.

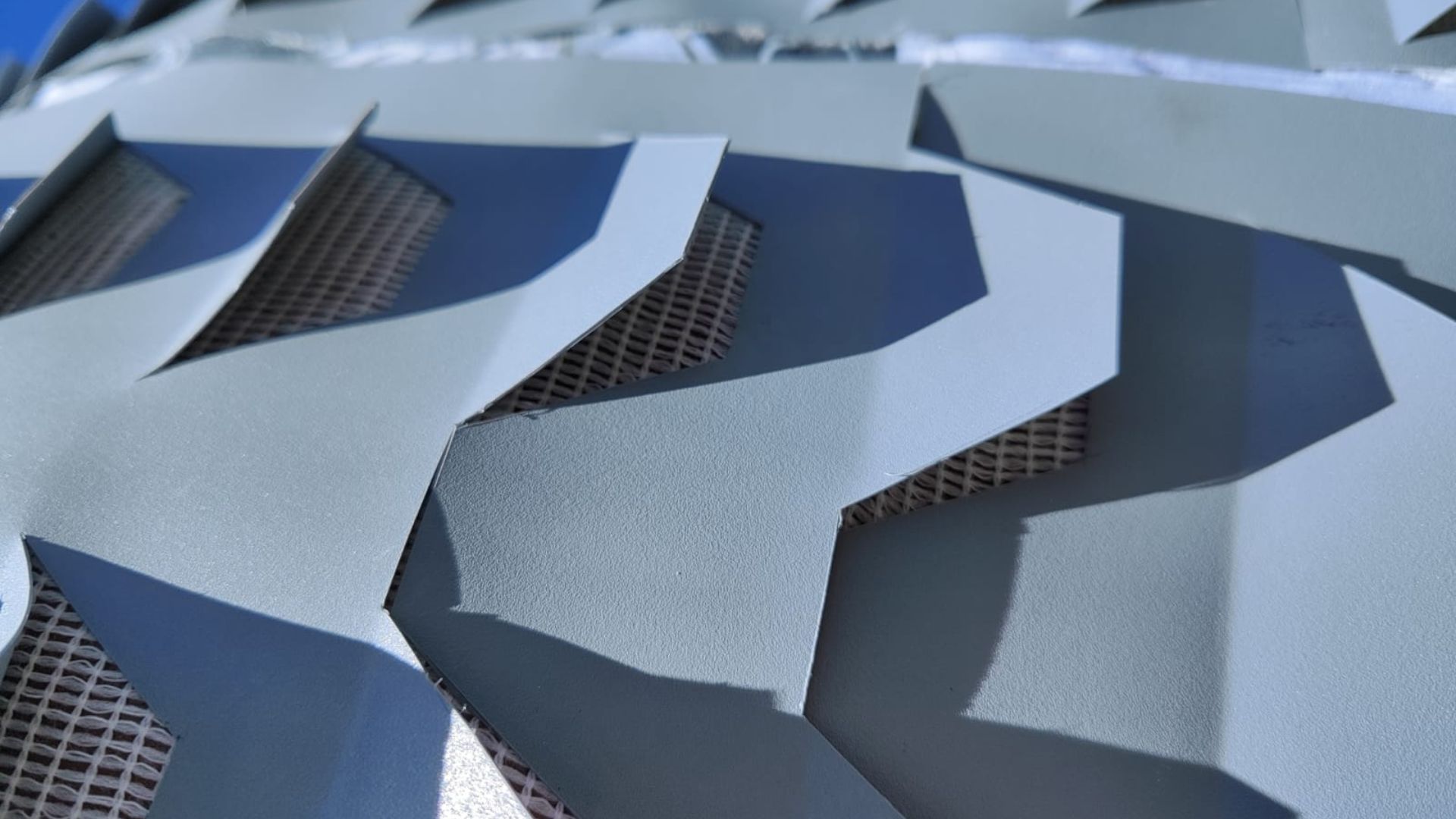

For these special writing and drawing instruments, Castiglioni and Cavaglià did come up with a trilobate arched shape which, thanks to its functional characteristics, could accomplish the true alliance between mind, hand, and object. The instrument itself turns into an ideal prosthesis of our hand and offers, with its peculiar trina shape, a specific way of use.

Team EGO.M

In the age of computers, the project interprets the beautiful challenge to transform an ancient object, sometimes seen even as obsolete, into a vivid real tool that is always necessary. Castiglioni and Cavaglià paper drawings do indicate precise conceptual and aesthetic wills to which Team EGO.M has contributed with its own intuitions and technical expertise to create a practical, democratic tool, easy to understand and use, ironic, made in Italy and least but not last, sustainable.

Combining a revolutionary material as graphene with the additional manufacturing 3D printing technology, CENTO3 was born. A writing tool that respects the project goal: innovation, sustainability, respect for quality and costs so as to make it affordable for the most.

Material – Graphene

It all starts from the pencil… Graphene is a material obtained in laboratories from the exfoliation of graphite and consists of a monoatomic carbon layer, organized according to a crystalline structure with hexagonal cells. Its very small thickness of 0.3 nanometers allows it to be defined as a two-dimensional material. It has the theoretical strength of diamond and the flexibility of plastic.

Depending on the carbon atoms layout, different materials with as many specificities are obtained. For example, when carbon atoms tie up to parallel layers within a reticular structure, graphite (the mineral used in pencil’s tips) is obtained. If instead, the structure becomes reticular with a 3-D growth, the diamond will show up. With only one atom thick, graphene is today the thinnest and most seductive substance in the world.

Flexible, thin, durable, transparent, waterproof, and sustainable, graphene is the material of the new millennium with ancient roots that sink into our daily lives… A pencil made of pencil!

Production Technique – Three-Dimensional Printing (FDM)

In additive manufacturing, starting from an empty space, the machine does deposit material only where it is needed, layer by layer until the complete projected piece is made. In this type of processing, the search for the right materials is fundamental. Innovative and above all biodegradable plastic polymers are used for 3D printing. In Fused Deposition Modeling (FDM) printing, polymers are produced in the form of filaments.

The PLA filament (Polylactic Acid), under certain conditions, becomes biodegradable. Depending on the environments in which it is abandoned it has an average life range from 1 to 4 years, against the +100 of plastics of common use. In normal conditions, it also has excellent mechanical properties and resistance to chemical agents.

3D production technique allows to perfectly respect the trilobate shape of the writing instrument, balancing aesthetics and grip and slowly blurring the horizontal lines on the tool’s fuse. Each fuse is made individually. The slow filling, the thickness of the walls and other important printing parameters determine both the final rigidity of the product making it resistant to shocks, and the aesthetic quality of the filament processing; ultimately, the lightness of the object thanks to the graphene filament.