ColorQuant, a groundbreaking, easy coloring of photovoltaic modules

Historically color has been avoided because of its negative impact on the system’s efficiency. An innovative technology based on coloring by interference was developed.

In 2022 Merck and Ceramic Colors Wolbring GmbH jointly developed the ColorQuantTM solar technology, challenging the idea of power efficiency loss of colored PV modules.

Increasing the application of photovoltaic panels in buildings and objects is needed and welcome in a society aiming at significantly reducing the carbon footprint generated by fossil fuels. This however is often disregarded as a viable option because of visual and esthetic concerns related to the reduced color options characterizing photovoltaic cells.

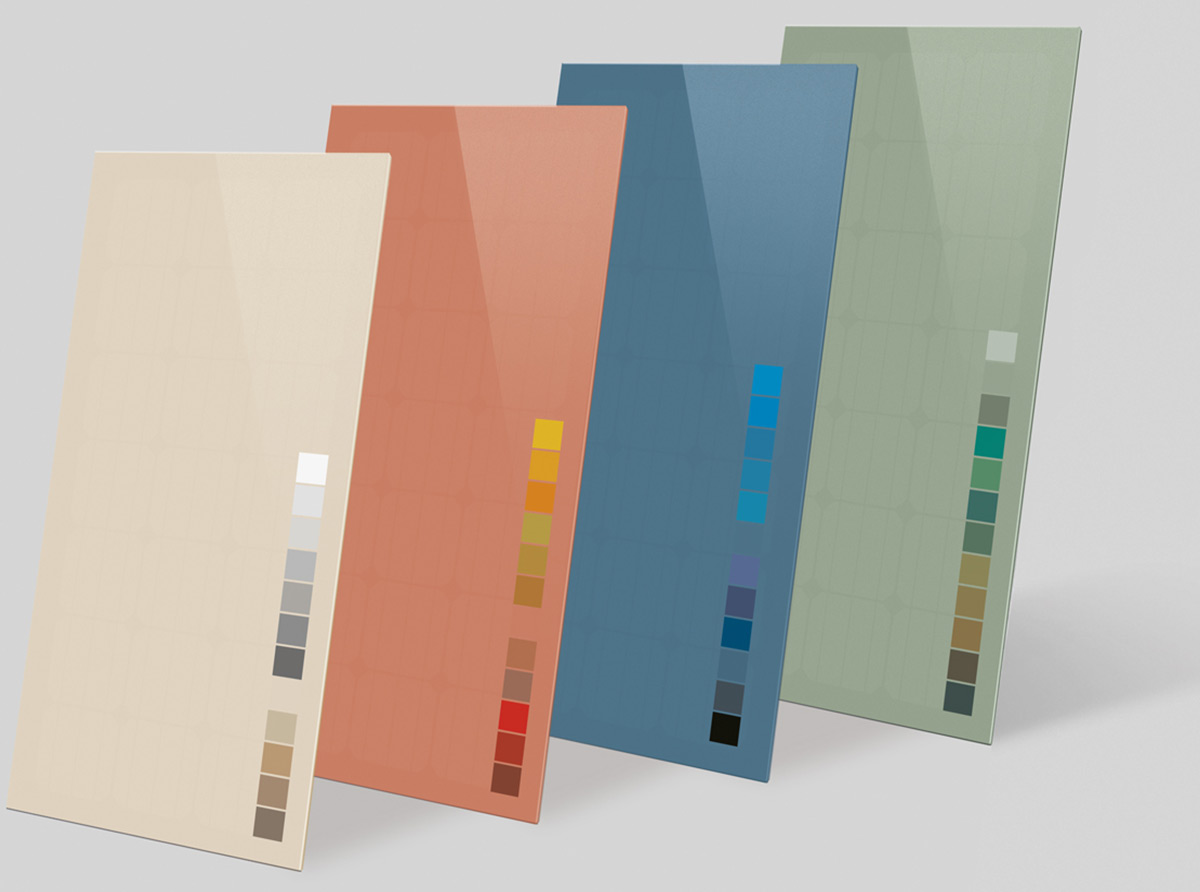

Historically color has been avoided because of its negative impact on the system’s efficiency. An innovative technology based on coloring by interference was developed. It offers an unprecedented palette to designers, architects, and infrastructure planners.

ColorQuant™ in short:

In search of an innovative solution

This technology fulfills all stability requirements, can be easily integrated into solar modules, and is convincing for its very good price-performance ratio as well as a reasonable service life in terms of efficiency and quality.

The studies building up to the development of ColorQuantTM investigated different approaches: from organic coloring, deemed unsuitable for degradation risks; to absorbing pigments, inefficient because light blocking, containing toxic elements and finally resulting in dull colors. Interference through dielectric stacks was too complex, light angle sensitive, expensive and unstable, while ColorQuantTM photonic pigments resulted in highly purified and validated colors, which ensure stability of solar performance and long lifetime of color performance.

The technological features

Photonic pigments can be implemented in PV modules in different ways. When it comes to glass color integration, color can be applied by screen printing, roller coating and spray application on the front glass, or in the encapsulant film that can be placed right after it. The scheme below shows the composition of a photovoltaic panel and where ColorQuantTM can intervene.

To obtain these colors, water-soluble ceramic pastes are used. The colors’ structure is based on coloring by interference. In this process, the incident sunlight is split up like in a prism once it hits inorganic and environmentally friendly pigments. The ColorQuant color layer lets through the light that the solar cell needs to generate energy.

Only those wavelengths are selectively reflected that are necessary for coloring. The result is only a minimal – around 10% – loss of power from the solar module. At the same time, a rich, however translucent color is achieved.

ColorQuant™’s applications

ColorQuantTM is posed to significantly impact the use of PV modules in visually sensitive projects at architectural and product design levels.

Extensive application of PV roof paneling has often become an unwanted feature in the built environment because of its visual presence, dark and in contrast with the surrounding elements due to the color limitations associated with its silicon-based modules, which can reach only blue to black tones. Most applications to date were geared towards architectural installations. However other product categories, which have typically found one and only aesthetic definition would naturally welcome PV cells or panels: automotive and transport, lighting, and many outdoor functional structures.

Access to an unprecedented palette of colors or the ability to create translucent finishings provide to designers a new vocabulary to experiment in a wider variety of products and, most significantly, of building integration. In fact, as ColorQuantTM PV colors were developed jointly by Ceramic Colors Wolbring and Merck especially for facade-integrated PV elements, this line of design and production can find further developments.

Pros and cons: an objective viewpoint

A technology capable of transforming the aspect of devices providing renewable energy has great implementation potentials, even more considering the colors are produced with water-soluble, environmentally friendly ceramic, no hazard labeling is required according to EU directives. For glass finishers who use ColorQuant colors, this means that there are no high additional or recycling costs for disposal, as color residues etc. can be disposed of without any special effort.

On the other hand, customized colors and appearance does not solve all problems of PV usage, i.e. in electric mobility systems, where the extension of the available support area or battery related issues represent the major restrictions.

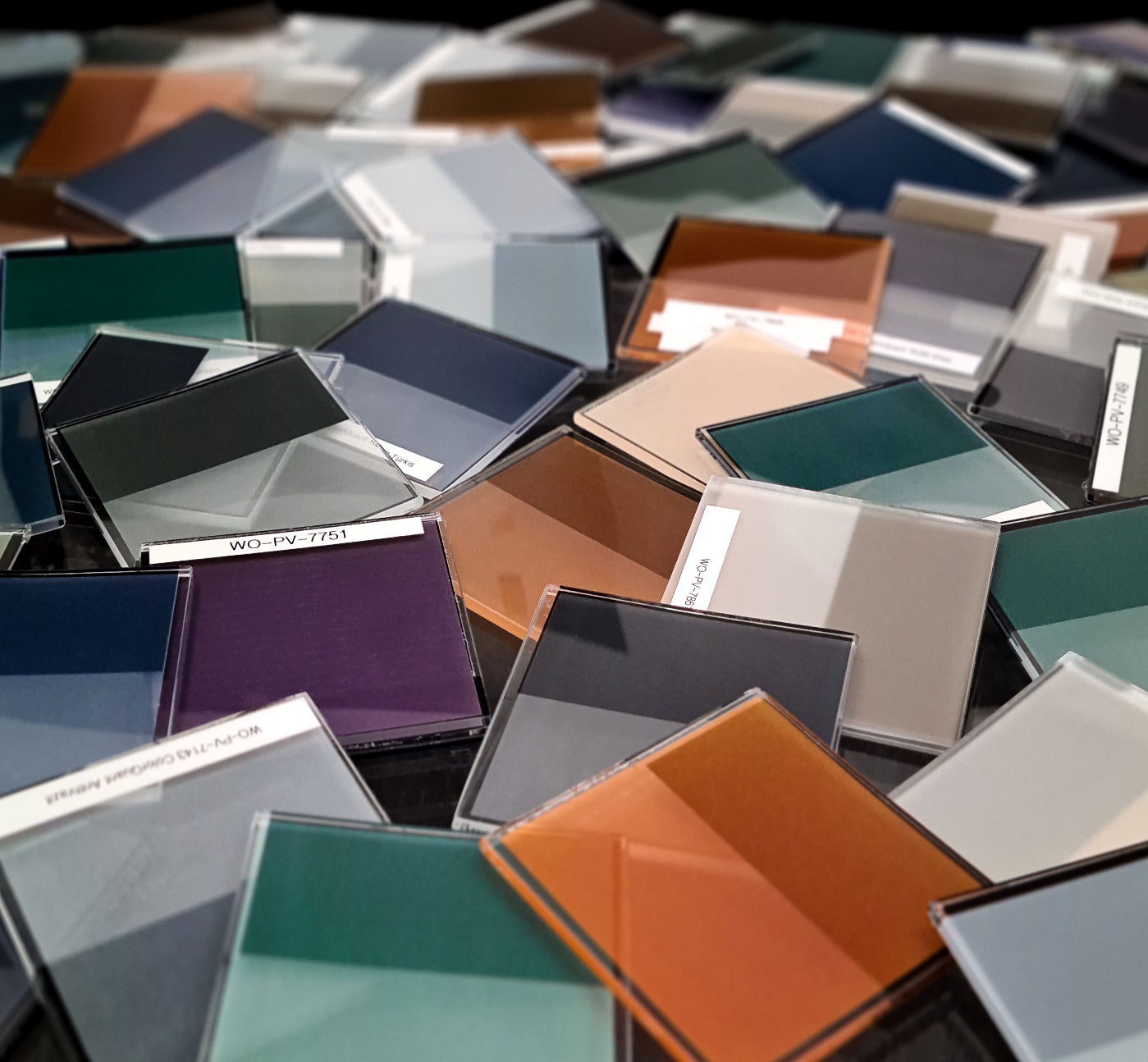

Who is involved? Players and logistics

Employing ColorQuantTM features to its best potential implies multiple players including PV panels manufacturers and glass finishers. Merck oversees its applications ensuring the implementation of all formats and sizes up to the jumbo format of 3210 × 6000 mm. The color palette is controlled and replicable so that a need for replacement can be easily met.