DIY products making design accessible for all – from children to the elderly

With an increase in demand for DIY home solutions – it’s time to use minimum materials to craft innovative sustainable and functional objects yourself! Are you ready?

From the Pollinator Kit by Checkerspot to Air-It-Yourself by Newtab-22, Ambessa Play Flashlight by Pentagram and Smartphone G22 by Nokia – there has been a rising popularity of DIY products among consumers from children to the elderly with an increase in demand for home solutions.

With the phrase “do-it-yourself” coming into common usage – one thinks of DIY as a 20th-century movement. However by no means is it a new phenomenon, its traditional roots go back much further stemming from the early 1950’s and 60’s. Did you know that? Allowing everyone to create as both a creative-recreational and cost-saving activity – it drives one to utilize minimum materials to craft sustainable and functional objects themselves.

Following the outbreak of the COVID-19 pandemic and changes in lifestyles – the global DIY Market size is estimated at USD 773.90 billion in 2023 and is expected to reach USD 915.26 billion by 2028, growing at a CAGR of 3.41% during the period 2023-2028. This significant increase in the adoption of innovative technologies is expected to drive the growth of the do-it-yourself market in the forecast years.

Gallery

Open full width

Open full width

For instance in order to respond to requests from designers for renewable materials, Checkerspot formulated the Pollinator Kit – an algae-based plastic prototype kit. “Historically, product designers, hobbyists and artists have been limited by the materials available to them from commodity-based suppliers – this strategy pigeonholes renewables, limits the scope of how they can be used and consequently narrows the impact they can have!” shares Checkerspot.

On the other hand, hoping to democratize access to clean air and establish it as both a public resource and a human right – Jihee Moon of Newtab-22 released Air-It-Yourself, empowering one to make their own low-tech purifier.

Air pollution – both indoors and outdoors – caused approximately 7 million premature deaths in 2022 – a risk that disproportionately affects poorer countries and households. “While air purifiers are usually expensive, the functioning structure of the product is not complicated – if you have a filter and a fan and have access to the instructional guide that I have developed, everyone can make similar products with ease!” Moon explains.

Additionally, Pentagram worked with child refugees to design the Ambessa Play Flashlight kit that can be assembled from parts designed to be easy for children to handle while teaching them about science and electricity. “For every kit purchased, another just like it will be delivered to a displaced child out of school!” says Pentagram.

Lastly, Nokia and iFixit launched the Smartphone G22 with a DIY repair kit – by providing the tools and instruction manual for people to use at home – they hope to offer an affordable alternative to external repair services that often come with long waiting times.

“People are starting to change their minds and want durable and sustainable things. It’s an economical and ecological necessity – we can’t continue to live as if the planet doesn’t need help. In the last 20 years, Right to Repair has become more important with more and more people integrating repair into their life!” iFixit shares.

Read on to explore these further!

DIY products – Read on to explore these further:

Pollinator Kit by Checkerspot

Allowing designers to experiment with making components from algae-based plastics – California-based materials company Checkerspot launches a casting kit, Pollinator Kit. This direct-to-designer kit allows producers to experiment with algae-based materials designed to replace traditional polyurethane resin – a fossil fuel-derived product found in many household items.

The material has a biomaterial content of 56% and can be utilized in the same molds used in fossil-based products, while the rest of the mixture is made from fossil-derived isocyanate. Utilizing biotechnology, they have been able to create a production method that harvests the oil from algae to make renewable building blocks for use in product design.

Microalgal oil is obtained from large industrial facilities – many of which are located in southern Brazil – where after mass fermentation, algae is mixed with sugars and then water is subtracted to produce the oil.

“This approach marries the efficiency of a highly productive, fast-growing, photosynthetic plant (sugarcane) with the efficiency of a highly productive, fast-growing, oil-producing microbe to make a very precise type of oil. The upshot is a lower land footprint, a far lower water footprint and a low carbon use relative to other ways of making oil!” shares Checkerspot.

Additionally, the oils are converted into polyols, which Checkerspot then converts into polyurethane in a facility in Salt Lake City. It can be further used for making products from jewelry and phone cases to surfboards and furniture and includes resin – a mixer as well as a choice of pigment, which is also made from algae.

Air-It-Yourself by Newtab-22

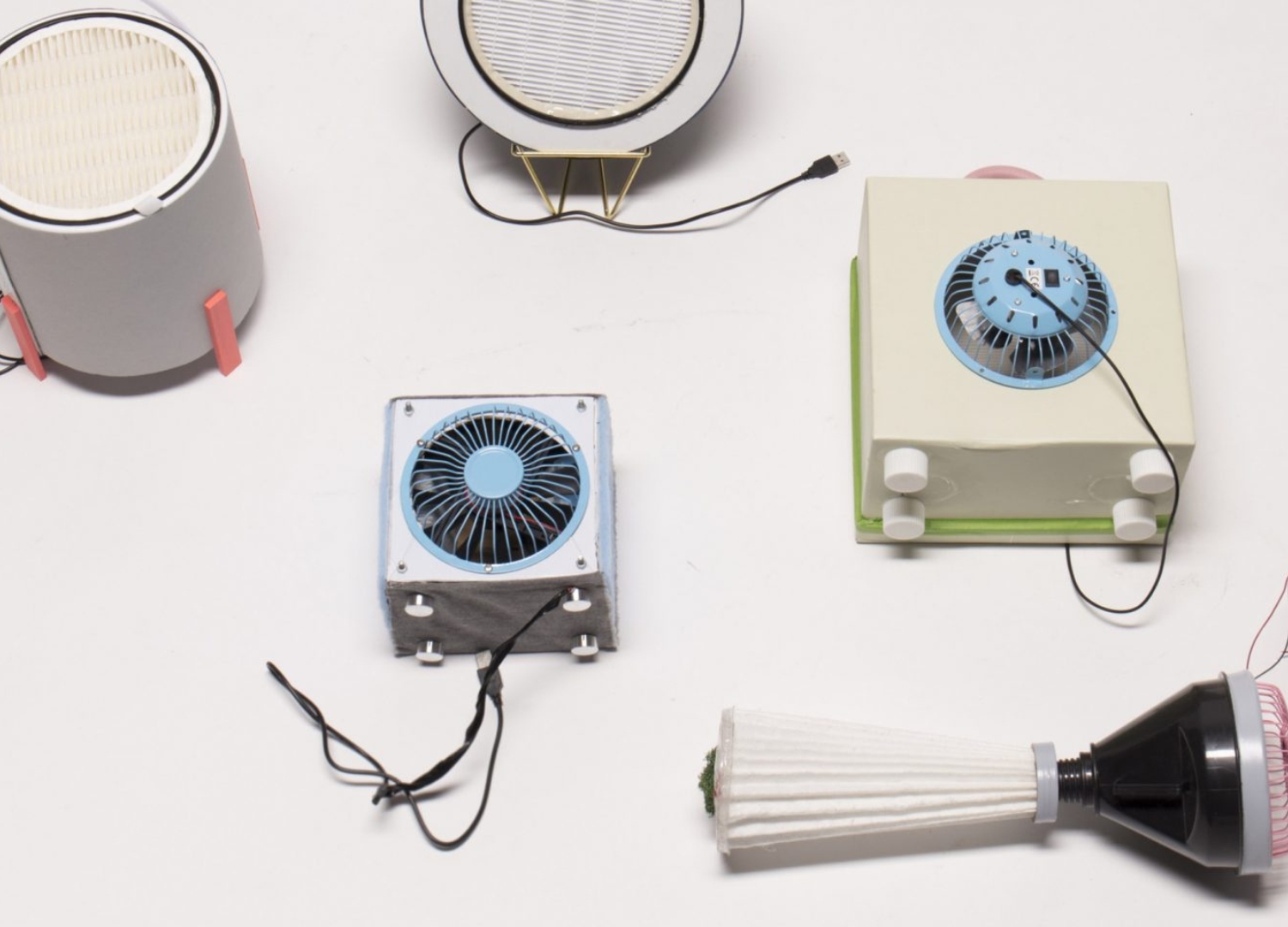

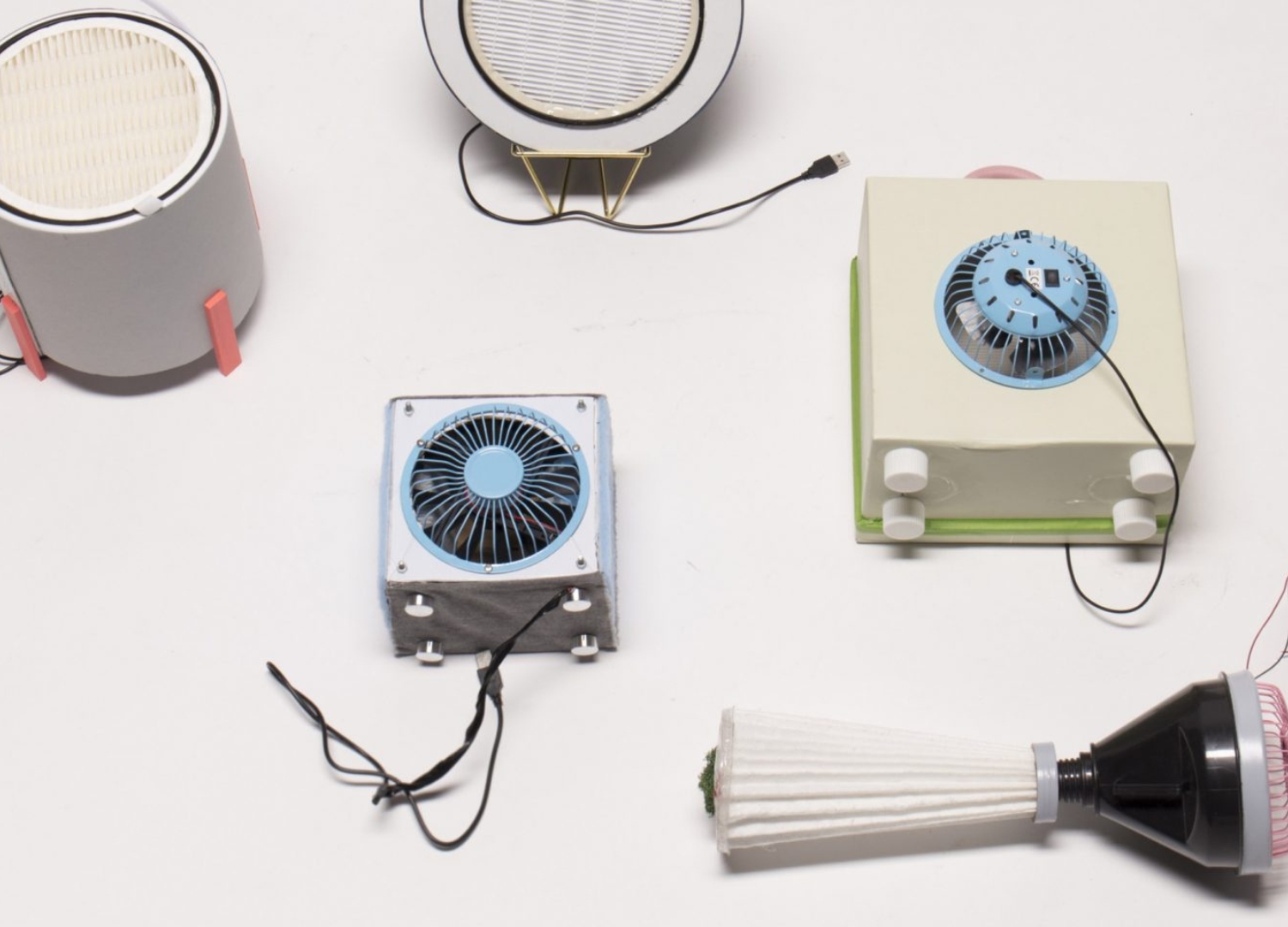

Jihee Moon of South Korean design studio Newtab-22 develops an open-source IKEA-style manual with instructions on how to build the Air-It-Yourself air purifier in under an hour using everyday items. From shoe boxes to plastic plant pots – this system utilizes household waste for parts and combines them with a small USB fan and a HEPA filter sheet, which can be easily purchased.

Making complete use of different household items but constructed using the same logic – she’s crafted various prototypes using the Air-It-Yourself system.

A large, hollow item such as a shoe box, oil funnel or a plastic plant pot is used to form the body, with holes on either end used to accommodate the fan on one side and the HEPA filter on the other. The contraption is sealed shut using glue and tape to prevent leakage and ensure all air that is sucked in by the fan is pushed out through the filter. Additional elements can be added for practicality, with bottle caps used as feet to raise the air purifier off the ground and hair curlers acting as handles so it can be carried from room to room.

The instructions were further designed and adapted based on interviews and workshops with residents in Seoul – where particle pollution levels are about twice as high as in any other major city in a developed country.

“The result is a product that everyone can make easily, taking less than an hour to make at an affordable price. Despite its DIY construction – the purifier was able to improve indoor particle pollution from a “very unhealthy” air quality index (AQI) level of 304 to a healthy level of three in only two minutes when Moon trialed the design!” Newtab-22 explains.

Ambessa Play Flashlight by Pentagram

To create a DIY Flashlight that will be sent to children in refugee camps – design studio Pentagram partnered with social enterprise Ambessa Play. The enterprise further brought in Pentagram partner Jon Marshall to develop the industrial design that has a flat, wallet-sized shape and operates on a battery-free wind-up mechanism.

“We developed about six to eight initial concepts for the external form, including standard cylindrical torch shapes. Children actually made the decision for us on the final design – they chose the flat rectangular form because it was the most compact and they liked that it fits into a pocket. They also remarked that this design allowed the flashlight to function as a handheld torch but could be placed upright shining onto the table surface like a lantern for reading!” shares Marshall.

Additionally, the finished flashlight has a lanyard so it can be worn around the neck – it can be wound up using a clip-on hand crank for fast charging, or with that removed, by using the dial on the front to keep the device topped up.

The winding charges a capacitor, which was further chosen to keep the design compact and avoid the safety issues of batteries. According to Ambessa Play – one to two minutes of winding creates enough energy to power the LED lamp for around 15 minutes. Lastly for the internal components, the Pentagram team focused on creating attractive colorful tactile details while simplifying the layout for ease of assembly – there are 10 components overall and 16 build steps.

Smartphone G22 by Nokia

Featuring replaceable parts and toolkits so that customers can fix their phone themselves – Finnish mobile manufacturer Nokia partnered with repair specialists iFixit to release the Smartphone G22.

The Nokia G22 – which comes in gray or blue – has a removable back panel made from 100 percent recycled plastic. Customers can purchase spare batteries, screens, covers and charging ports from the iFixit website.

Each part comes with a set of corresponding tools from a pair of tweezers to a suction handle and opening picks. Users can then read the accompanying instructions detailing how to solve common smartphone issues – including changing the battery, charging port and replacing the screen.

Additionally, the tools are made of Delrin – a stiff, engineered thermoplastic often used to make bearings, fittings and various electrical insulator parts while the screwdriver is made from steel. iFixit drew on its experience of fixing customer phones to identify the most common smartphone repair requests and further structured the repair instructions to be understood easily.

“Over the years – we’ve learned firsthand what repairs will be easy or what challenges people will face. With patience, the right tools and guides, anyone can fix anything!” Kyle Wiens, iFixit Chief Executive Officer says.