ECOncrete brings concrete to life with man-made rock pools

Maor Bezner, Design Director of eco-engineering company ECOncrete, talks us through the company’s latest project Coastalock, a coastal defence system with textured and indented surfaces that encourage organisms to latch on and colonise it.

Today we use concrete more than any other substance, apart from water, accounting for 8% of total carbon dioxide emissions.

Approximately 70% of the world’s man-made marine structures – jetties, breakwaters, harbour walls and sea defences – are built using concrete. However, such structures do not capture ecosystem services.

Thus, when concrete meets water, marine life subsequently suffers. This was all too clear to ECOncrete®’s co-founders, marine biologists and innovators, who believed that they could develop solutions good for both the structure and the environment.

Through biomimicry and ecological engineering, ECOncrete designs concrete infrastructure to regenerate native marine life, reduce ecological footprints whilst also making infrastructure stronger and exceeding international industry standards.

The concrete’s patented technology invites species like oysters, corals, seaweed, algae and rehabilitates habitats for fish and even octopi, generating a huge carbon sink and strengthening the overall structure.

ECOncrete was designed as an alternative to traditional man-made flood defences

Armouring units are modular building blocks of marine infrastructure, which provide coastal defence against powerful forces of water.

ECOncrete’s COASTALOCK technology builds upon the traditional armour design to provide a solution beneficial for the local ecology, whilst maintaining its strength for effective coastal protection.

COASTALOCK technology is an interlocking single-layer armour unit. It provides shoreline stabilisation, as the product design gives it the adaptability to be used anywhere where conventional single-layer armour is needed, such as in breakwaters, revetments and riprap embankments, in full replacement of conventional concrete armour.

Furthermore, it fits the unique properties of the coastline, as the steeper slopes facilitate the interlocking of the units.

Despite being a more ecologically and environmentally positive alternative, COASTALOCK’s design still retains traditional concrete’s fundamental strength and durability to effectively attenuate wave energy and limit coastal erosion.

It is an armoured fibre-reinforced concrete unit weighing about 3.5 tonnes and features a patented admix that complies with and exceeds the industry standards whilst reducing the harmful effect of concrete on the ecosystem and increasing biogenic build-up.

Dive into the research and development of Respyre’s bio-receptive concrete and moss-covered facades, which give architects and designers the tools to turn any and every surface green.

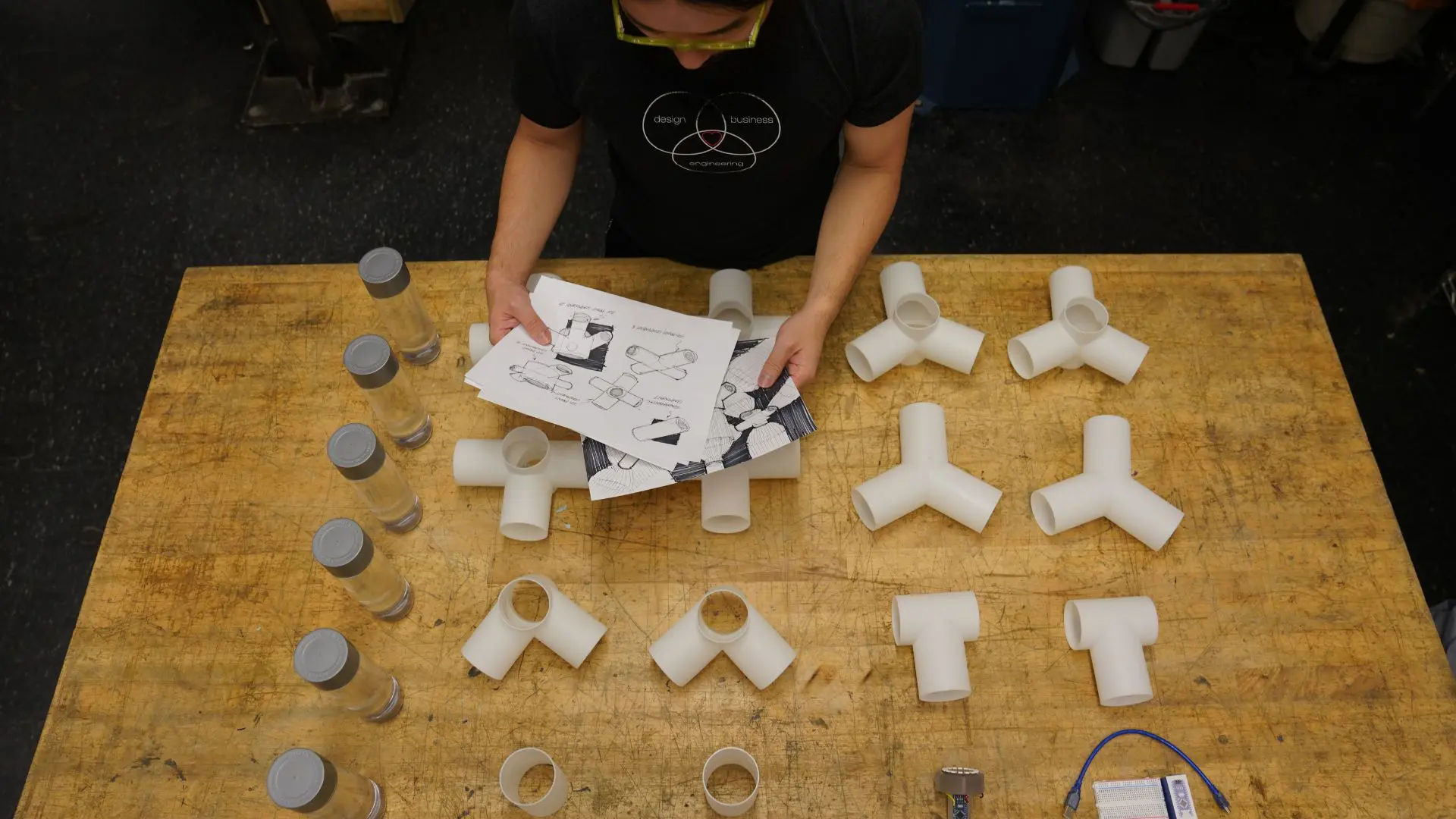

ECOncrete designed a product to balance the technical requirements of the unit along with the biological requirement of the local species

ECOncrete specialises in finding mass production solutions to manufacture responsible concrete infrastructure, by incorporating innovative ideas into standard concrete manufacturing technologies.

The admix and unique bio-enhancing designs can be incorporated into any design to fit the specific need of the project and location.

Throughout the design process, ECOncrete works closely with industry leaders, ranging from concrete machinery providers and coastal construction such as BESSER and BAM, to concrete and cement giants such as Holcim and world-leading marine engineering firms, to bring the designs to the mass market.

During the development process of the COASTALOCK solution, we formed a partnership with the Port of San Diego, which commissioned a pilot project to protect Harbor Island.

Prior to the partnership, Harbor Island’s shoreline protection, such as the riprap rock mound, offered very limited habitat value.

Thus, to match the needs of the project, ECOncrete designed a product to balance the technical requirements of the unit along with the biological requirement of the local species – with the outcome being COASTALOCK.

The project installed 72 interlocking armour units to increase both the structural and biological performance of the shoreline protection.

ECOncrete’s COASTALOCK solution has significant benefits to the products on the market, which use traditional concrete.

This is because it effectively protects the coastline without sacrificing the local environment and biodiversity.

Both the durability and the unique texture of the concrete mean that it acts as a firm growth point for marine species, thus encouraging natural habitat creation and marine life like oysters, coralline algae, corals, kelps and more to settle on the concrete.

The calcitic organisms draw carbon dioxide from the water to build their shells, transforming a passive structural unit into an active carbon sink.

Furthermore, these organisms also build up a CaCO₃ (calcium carbonate) layer.

This layer of bioprotection encrusts the units in a living “armour”, adding weight and stability, buffering hydrodynamic forces and chlorides. Increased strength is a result of the admixture, which can be incorporated in any and every marine concrete solution.

The solution also reduces the levels of Co2 emitted, in comparison to traditional concrete.

This is because the admixture is made of >90% recycled and by-product materials, offering a significant carbon reduction.

The bio-enhancing admixture promotes biocalcification and photosynthesis, offsetting up to 2 tonnes of CO₂ for every kilometre of infrastructure annually, the equivalent of 100 trees.

Finally, the product is cost-effective, with reduced environmental mitigation penalties and facilitated permitting.

Furthermore, standard casting and curing rates, as well as a three-day installation means it remains easy and attractive for those building with it.

Thus, this highlights the solution’s viability for a range of marine construction projects.

The future of ECOncrete

Backed by new investment and a strong team of environmental experts, ECOncrete looks ahead to another exciting year of fulfilling its mission: to transform the way our concrete coasts look and function so that where the ocean meets the shore, life thrives – above and below the water.

ECOncrete hopes to expand the use of its COASTALOCK solutions to protect more coastlines around the world, whilst enabling the healthy growth of natural habitats.

This company has found an energy-neutral way to transform organic waste into a valuable pigment and material additive: read how OurCarbon turns sewage sludge into a carbon-negative material.