A product made from industrial waste rooted in local tradition

Derived from local wool waste streams, Mariantonia Urru is developing innovative padding solutions that combine renewable resources with circular design principles, offering a sustainable alternative to conventional products.

In recent years, there’s been a growing need to embark on a path of ecological transition, shifting design away from traditional practices towards more sustainable solutions that include recycling and reuse of both pre- and post-consumer waste. In this context, the work of Mariantonia Urru (MU) aims to introduce processes and product innovations through targeted research, into the unexplored potential of the wool industry, promoting initiatives aimed at enhancing the sector’s development opportunities.

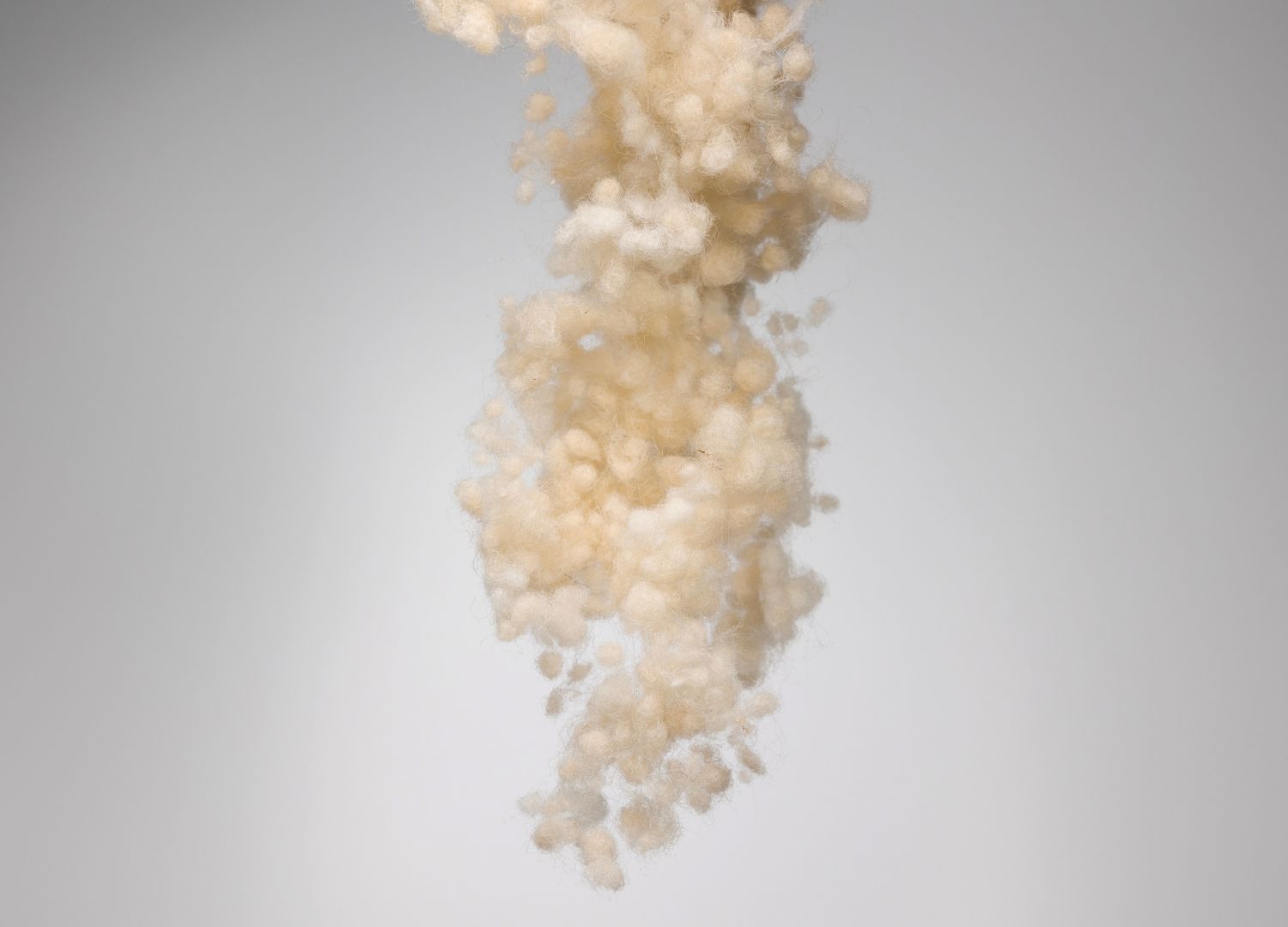

Wool, a naturally renewable material, is in fact, at the heart of the brand’s philosophy, which focuses on local resources and craftsmanship for low-impact production. Established in 1981 in Samugheo – a village on the island of Sardinia, Italy – the brand soon made a name for itself with rugs and textiles that combine tradition and contemporary design. Today, it is expanding its business with new sustainable solutions, such as needled pressed panels from 100% wool waste, semi-rigid panels made from a mixture of wool and bi-components, wool and hemp padding, and wool pearls for padding.

Gallery

Open full width

Open full width

In this way, wool becomes the foundation for a new line of products that can be adapted to different sectors thanks to its versatility and intrinsic properties that set it apart, such as: hygroscopicity, insulating, sound-absorbing and naturally fire-resistant properties. These qualities make it a valuable resource for developing new opportunities for circular innovation, with applications ranging from interiors and furniture to automotive, reaching the fashion industry.

When used as a replacement for oil-based padding materials, MU materials represent a highly performative alternative. It can receive fire-retardant treatments and respond to different uses as it is provided in different densities and sizes. All materials can be custom-cut from a maximum dimension of cm 210 in width and unlimited length. Thickness is up to cm 20, resulting in different softness levels.

Semi-rigid fiber panels are suitable for core padding while soft fiber pads, bicomponent (wool and hemp) or 100% wool based, are shapeable and dust-free. Vertical fiber pads are made from short wool fibres, arranged vertically and distributed in a radial pattern. They naturally conform to the shape of its base, even around angles, curves, and irregular forms. Flexible, shock-absorbing, highly breathable, they adapt to complex surfaces without compromising structure or comfort.

Voluminous yet light, MU panels and pads are produced in Sardinia and shipped worldwide. The company provides custom samples and can meet industrial-scale manufacturing needs. While these naturally engineered materials have been developed only in recent years—with new consistencies and features still being tested—wool itself has been used as a padding material for centuries, if not millennia. Time has effectively certified the performance and durability of this base material.

MU wool settles itself as a highly valuable material, promoting circular practices thanks to the reuse of local resources, and the transformation of a by-product into a new opportunity. In this way, the company not only provides an example of a sustainable model, but also strengthens its bond with the local area and its traditions. MU looks to the future with an innovative approach, without compromising on the quality of craftsmanship that has its roots in the past and represents a wealth of knowledge, techniques and culture.