Morici’s production processes behind its Tellux collection of luxury boxes

Some four decades of experience culminate in Morici’s Tellux collection, defined by its intricate combination of materials mastered by the company’s highly skilled artisans.

Founded in Le Marche amongst a breathtaking backdrop decorated with idyllic hilltop towns in 1979, the beautiful Italian landscape has long been an inspiration for luxury accessories and furniture brand Morici. For forty years, the company has translated its love of natural materials and time-honoured techniques into a unique collection of homewares, from writing desks and table lamps to cigar cases, jewellery boxes and ashtrays.

Morici has also manufactured wood (and leather) accessories for the most important companies in Europe including Luxury Living Group and Kering S.A. . The draw is the company’s intricate mastery of materials alongside other artisanal practices and innovative production technology.

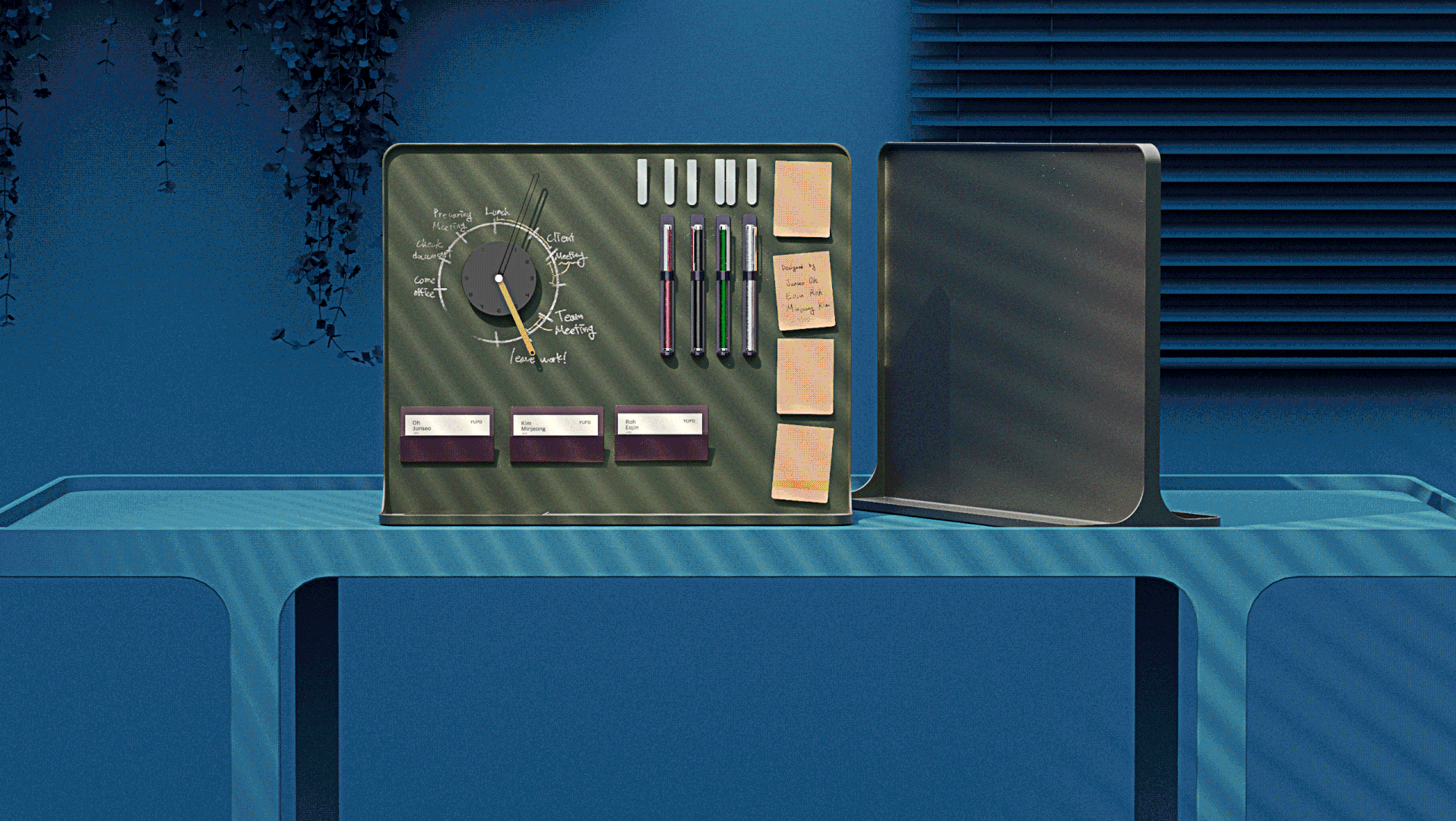

To showcase its commitment to craftsmanship, the company is taking us behind the scenes and showing off the production behind its Tellux collection, a series of luxury boxes defined by their geometric lines and precious woods including radica, ebony, rosewood, ash and bolivar.

Gallery

Open full width

Open full width

Morici’s Tellux collection – Design Process:

Step One: Design

“From the start, the objective is to enhance the highly artisanal identity of the brand through the expressiveness of the product,” explains Morici. “At the point of design, we explore all the possibilities as a result of complex manufacturing processes.” Envisioned by Morici’s Art Director Marco Fuligni of Fudesign Studio, the new Tellux collection was created to enhance the highly artisanal identity of the brand through the expressiveness of the product.

Juxtaposing precious woods of different textures and colors, the collection conceptualizes nature within a dynamic framework. The intention was to transform scenery into a graphic language informed by the company’s mastery of color and its ability to create striking, three-dimensional patterns.

“The product comes alive through an in-depth study of the artisan processes and the careful selection of materials and color combinations,” the company adds. A network of lines encloses different woods. Contrasting materials dialogue together: wood, fabric and metal form a product on the surface of which is impressed by the metaphor of a natural yet human landscape.

Step Two: Carpentry

Next, the technique is beautified by a complex geometrical design that flows uninterruptedly over the surfaces and adds character to all sides of the product. At this point, the process is directed by artisan production methods, which merge with meticulously designed elements to generate three-dimensional effects and reach the product’s final form. “The construction of the object follows a specific project but is enriched with numerous manual steps that make each product unique,” says Morici.

Each piece comprises wooden veneers of various essences colored with natural dyes, their characteristics are carefully chosen with the aim to create an elegant, balanced finish. These pieces are laser cut according to the design, which the craftsman prepares. In this case, the finish conveys a sensation of “bare earth” enriched by metallic reflections, and provides a coordinating element for the entire collection, along with the subtle, gold-finished, geometric lines surrounding precious woods like radica, ebony, rosewood, ash and bolivar.

Step Three: Painting

Then, the item is subjected to various layers of paint to strengthen the outer surface and create a quality product that lasts over time.This completely manual phase of the process is entrusted to the sensitivity of the craftsman who, through countless steps, protects the surface of the product.

“The scrupulous attention paid to this phase combined with the complex construction of the object, results in an extraordinary surface effect in the products,” explains Morici. “This enhances the shine of the veins and pigments, but above all gives an elegant three-dimensional effect to the texture.”

Step Four: Sanding

Once the protective layer of paint has been consolidated, the product undergoes numerous sanding steps carried out by a specialized operator with the aid of manual tools. This achieves a planar surface, which is extremely smooth and enhances the value of the most complex details including corners and junctions.

Step Five: Polishing

“Before moving on to the subsequent and definitive assembly and coating phases, each product of the Tellux collection undergoes a further surface finishing intervention,” says Morici. The finish being referred to here is polishing, which is carried out by an artisan whose knowledge of abrasive textures and how much pressure to exert, restores an unmistakable shine to the final product. As a result, the boxes boast a vivid brightness that enhances the wood grain.

“At Morici, the steps that lead to the definition of a product—even the simplest—are innumerable,” says the company. “Scrupulous and mainly manual processes ensure attention to every detail, the uniqueness of the product and quality of the design.”

“For the brand new Tellux collection, all of this is even more significant as it is an original vision as it investigates new expressive languages for furnishing products, supporting in a game of mutual exchange between innovation and craftsmanship.”