Philips MyCreation lights up global spaces with advanced 3D printing technology

The lighting brand is reshaping the landscape of luminaire production with its groundbreaking, 3D-printed solutions.

In a world where sustainability is no longer an option but a necessity, Philips MyCreation is leveraging the power of 3D printing to usher in a new era of eco-friendly manufacturing. At the forefront is an innovative use of recycled materials to create remarkable lighting that saves on time, energy, waste and transportation.

This revolution relies on 3D printing as an alternative to traditional methods, aligning perfectly with the principles of a circular economy. With raw materials derived from recycled sources and a commitment to end-of-life recyclability, these sustainably printed luminaires embody the essence of sustainability, featuring a meticulous disassembly concept, ensuring that nearly every component can be reused or recycled, minimizing waste and contributing to a closed-loop system.

As well as embracing a circular economy ethos, the brand unlocks unprecedented design possibilities. By sidestepping the constraints imposed by traditional tooling, bespoke luminaires are crafted with unparalleled flexibility and speed. This on-demand production not only reduces inventory but also enables small trials and unique, one-off pieces. It doesn’t matter if a client needs 1 or 1,000 pieces— it offers extensive design options and can make anything bespoke.

As we delve into this transformative journey, 3D printing takes center stage, prioritizing energy efficiency, durability, and reliability. More than just a technological marvel, it is a catalyst for new business opportunities, offering the potential to secure large contracts with clients eager to embrace the latest in customizable solutions.

Join us as we explore three major projects where Philips MyCreation has exceeded the visionary expectations of its clients, bringing together innovation and design to shape a more sustainable future worldwide.

Philips MyCreation lights up global spaces:

PLUS retail

Recognizing the pivotal role it plays in creating an optimal client experience, Dutch Supermarket PLUS retail sought lighting for its 500 stores across The Netherlands. It started with a proposal from their design agency that seemed promising, aligning with the new store’s style. However, the proposed concrete lampshades presented challenges in both production and application—being heavy, difficult to install, and lacking in sustainability.

Undeterred, the quest began and PLUS joined forces with the brand to reimagine their initial ideas using 3D printing. Focused on enhancing the client experience, the project sought to illuminate stores with a personalized ambiance whilst addressing the challenges with traditional concrete lampshades proposed by their design agency.

Leveraging 3D printing, the duo opted for bespoke pendant-style lights that seamlessly integrated into the store’s plan. These lightweight, affordable pendants not only met design aspirations but also facilitated easy installation, reducing build times significantly. The result is a harmonious blend of form and function, achieving the desired shape, size, and atmosphere while authentically replicating the concrete look.

Crucially, sustainability was a key focus. The entire luminaire was 3D-printed from recycled plastics, aligning with PLUS’s eco-friendly brand positioning. This commitment underscores the transformative impact of 3D printing in crafting bespoke, environmentally conscious solutions.

As part of this partnership, Philips MyCreation has not just provided light; it has illuminated 500 supermarkets with a perfect glow, showcasing the power of the additive manufacturing in creating tailored designs experiences achievable in just 3 months, from concept to final product

Taipei 101

Philips MyCreation orchestrated a transformative experience in a collaboration at the heart of Taipei 101, the renowned skyscraper in Taiwan. This visionary project, executed in partnership with the building’s design team, aimed not only to craft a well-designed space but also to ascend to new heights, creating a unique and inspiring haven in the sky. More than a mere aesthetic endeavor, the project set out to make a meaningful impact, showcasing a dedication to the well-being of the planet.

Adopting a circular design concept for the SkyPark, every aspect was carefully considered for recyclability, reusability, and responsible material ownership. This commitment extended to the incorporation of sustainable lighting solutions, aligning seamlessly with the overarching goal of circular design principles.

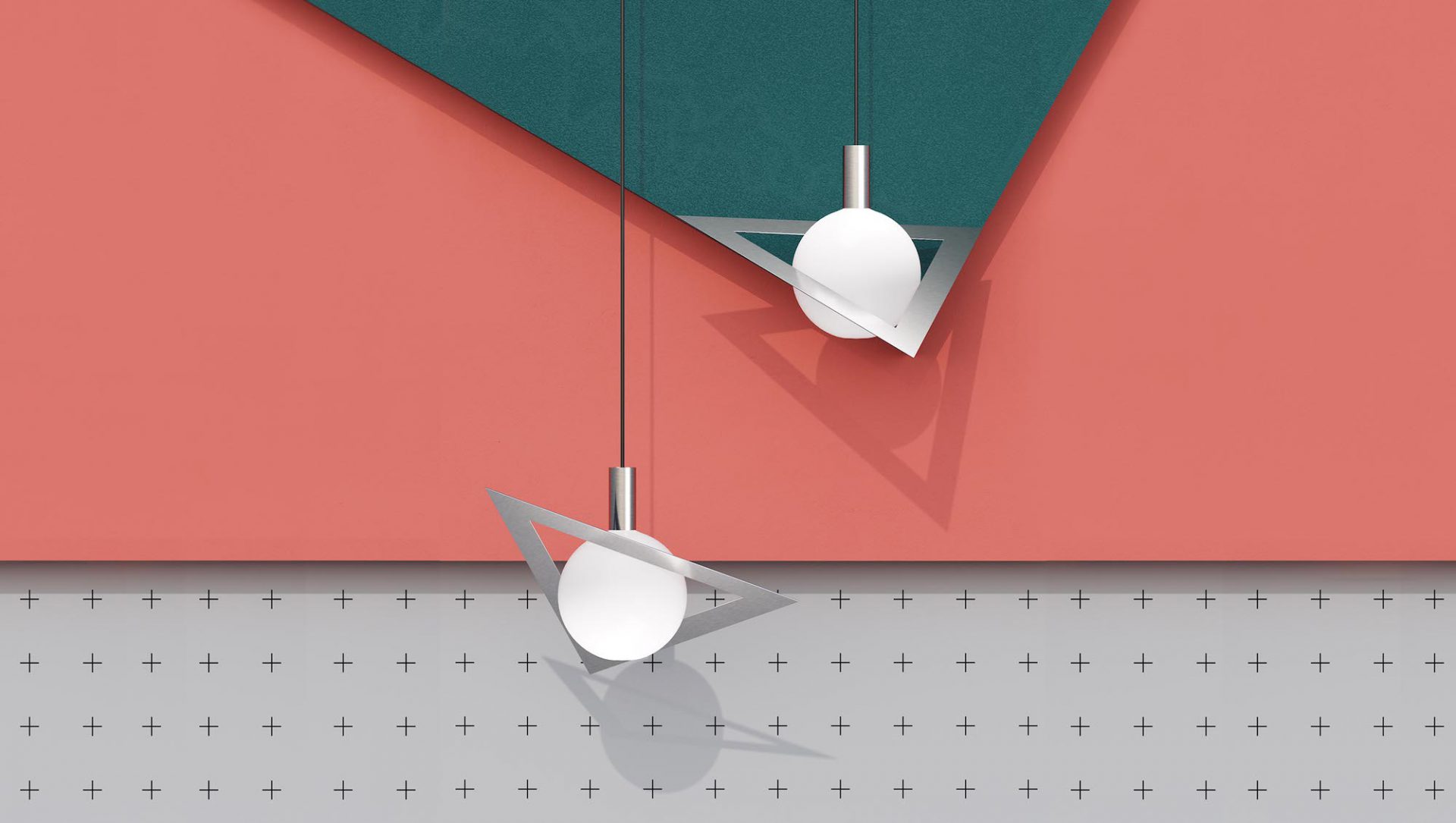

Enter Philips MyCreation, a pivotal player in bringing the circular design vision to fruition, proposing a solution that surpassed expectations – 3D-printed pendant lights featuring modularized designs, a forward-thinking approach that utilized recycled materials and introduced a disassemblable design, perfectly aligning with the circular ethos.

The impact was swift and impressive — printing on-demand not only eliminated waste during production but also made a substantial reduction in emissions, seamlessly fitting into the circular design concept. In less than a year, this collaborative effort birthed a lighting concept that continues to captivate visitors.

As a testament to the success of their partnership, Taipei 101 looks forward to expanding this transformative experience throughout the entire building. Having nurtured a longstanding relationship, including prior collaborations on façade lighting, this latest venture stands as a significant milestone. The skyscraper anticipates continued innovation and collaboration, ensuring an ongoing evolution of its illuminated spaces. The future promises to be bright, sustainable, and filled with exciting possibilities.

McDonald’s Corp

Embarking on a worldwide collaboration, Philips MyCreation worked hand in hand with McDonald’s Global Design Team to illuminate the brand’s 38,000 restaurants across the world with bespoke pendant lighting. This ambitious project aimed to conquer formidable design challenges, marking a transformative partnership that surpassed expectations.

Addressing non-negotiables including ownership of intellectual property, scalability within tight timelines, high durability, and cost-effectiveness, the duo developed “A Touch of Archery,” a design masterpiece with a customized, hemispherical, translucent pendant. A final non-negotiable was that the pendant should shimmer like velvet, boasting an embossed pattern in a warm tone, a complexity that would require a challenging mold.

The brands’ 3D printing prowess proved to be the key to overcoming these challenges, aligning seamlessly with the project’s demands, and offering a swift two-round sample process—the team not only met the design intent but achieved final sample approval in less than three months.

The collaboration emphasized sustainability, aligning with McDonald’s ambitious 2030 carbon footprint reduction goals. The use of 3D printing with recycled materials allowed for global-scale production closer to the point of use, addressing environmental concerns and speeding up production.

The result is a global installation of pendant lighting fixtures across McDonald’s restaurants, which not only meet McDonald’s stringent standards but also serve as a learning experience, uncovering the innovative capabilities of a global partner.

As McDonald’s continues its commitment to cutting-edge design, Philips MyCreation emerges as the premier collaborator for creating and developing unique luminaires on a global scale, promising an exciting future of stunning designs and innovation.