Philips MyCreation circular approach brings sustainability to the next level

Sustainability matters: Philips MyCreation values and practices setting the brand to new ambitious goals.

Contributing to a circular society, Philips MyCreation luminaires make a statement by demonstrating how technology and sustainability can be a powerful and beneficial match that holds the potential to play a significant role in addressing environmental challenges in various ways.

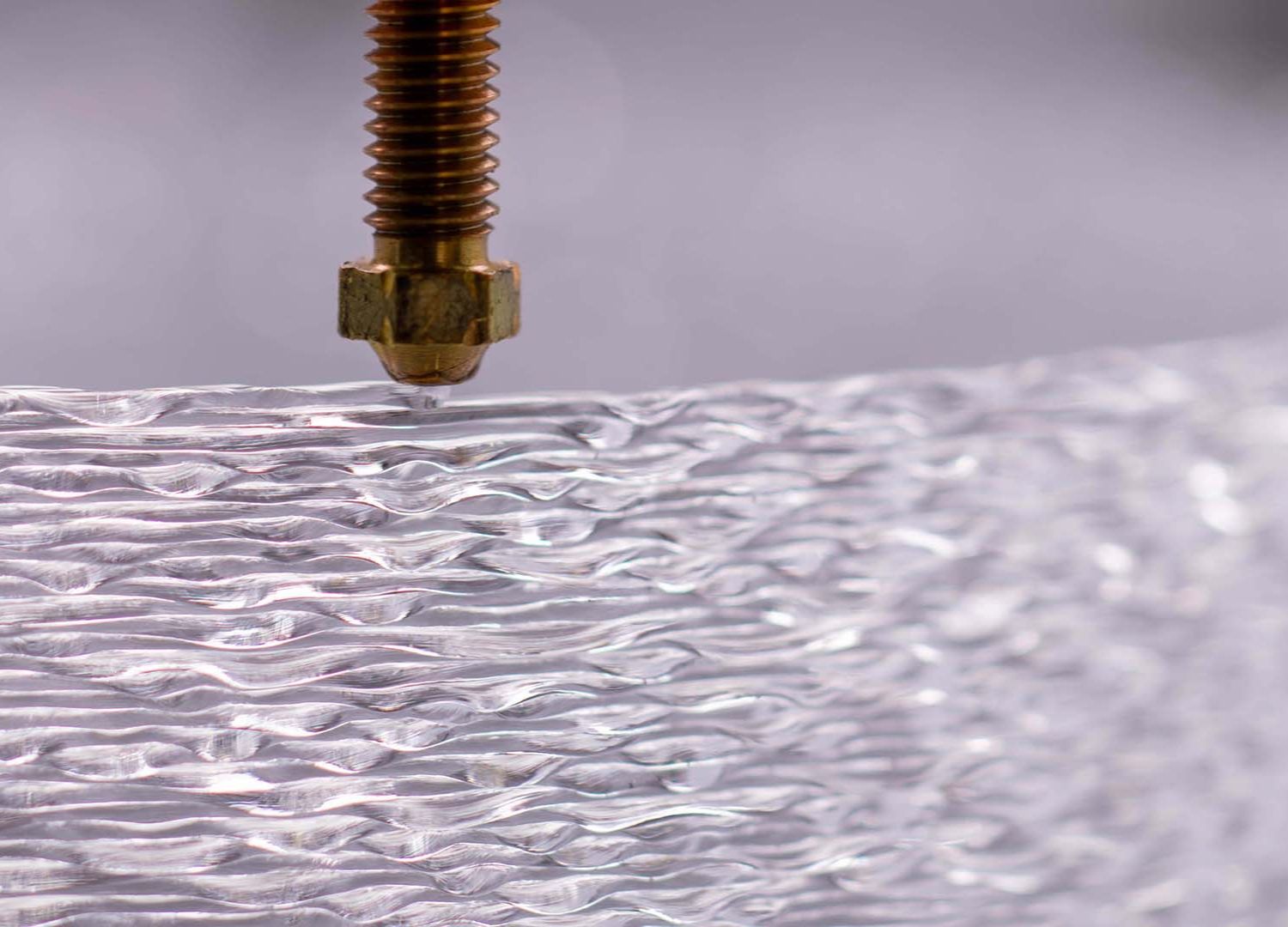

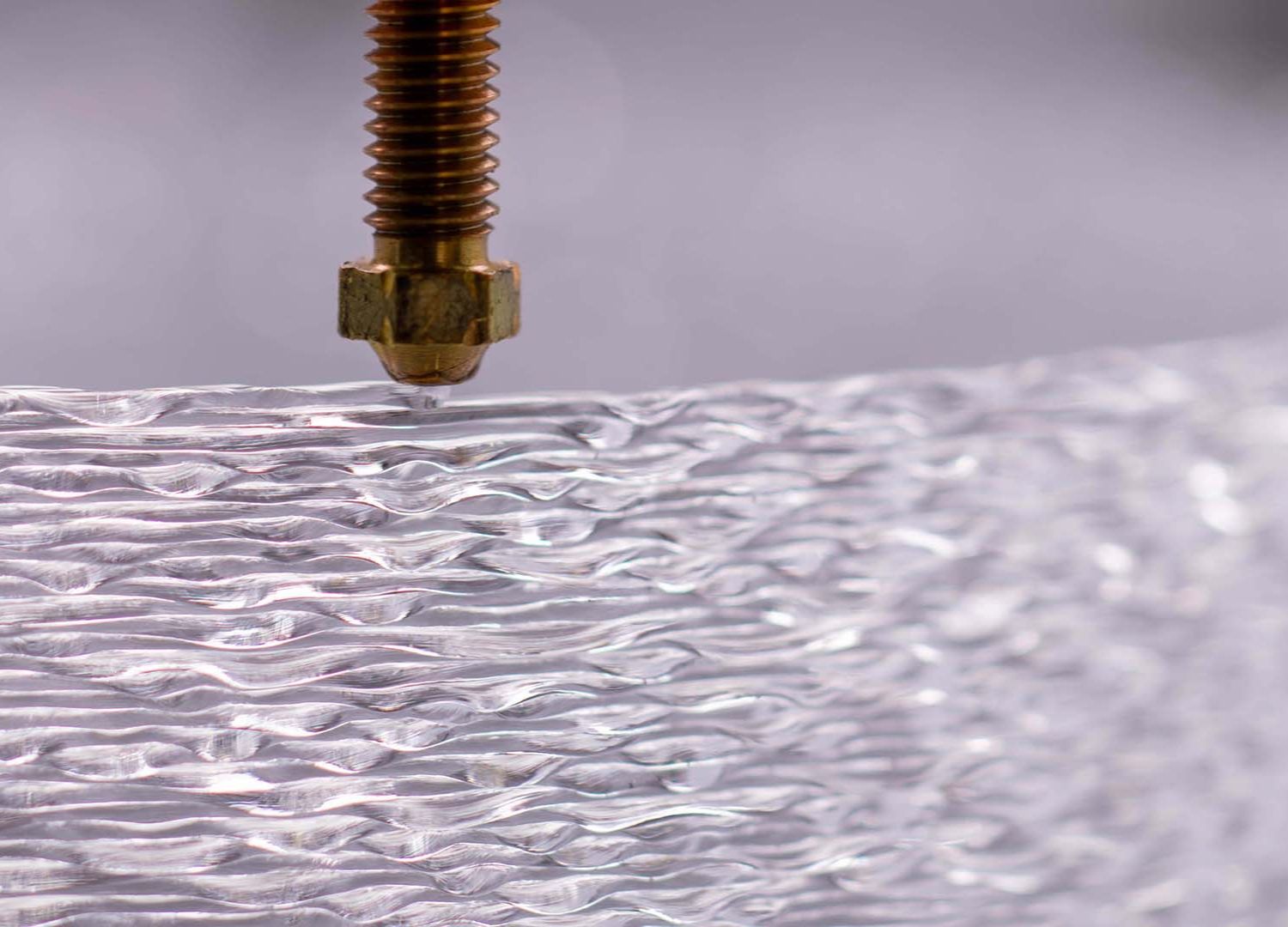

By making use of 3D printing as a solution to sustainable challenges, the brand’s printing-on-demand approach prevents the creation of excess stock, ensuring that if a product hasn’t been produced, it won’t contribute to pollution. Similarly, this production method not only minimizes waste but also utilizes existing waste, such as fishing nets and water jugs, to create new products.

In the future, the company aims to reuse its own End-of-Life luminaires by repurposing the material for printing entirely new products.

This distinctive approach used by Philips MyCreation in embracing circular production is particularly fitting, given that it is a brand under Signify, the global leader in lighting. Signify, known for its “Brighter Lives, Better World” strategy, has achieved carbon neutrality in its operations since 2020 and exclusively utilizes 100% renewable electricity.

Beyond these operational achievements, the company distinguishes itself with a holistic approach to design and production.

For Philips MyCreation, sustainability is not just a value, but a guiding principle. Embracing a circular economy, the company transforms material flows from linear to closed-loop, finite to renewable, and virgin to recycled and bio-circular. Having an ISCC Plus certification, the entire supply chain contributes to environmentally, socially and economically sustainable production.

By making a Life Cycle Assessment (LCA) for each product series and creating an Environmental Product Declaration (EPD) to communicate the outcome, the brand can provide the requested environmental data that is usually required for the many hundreds of environmental or green labels and certificates.

Among the several certifications achieved, certain North American products received the prestigious Declare certification issued by the International Living Future Institute. This label emphasizes the brand’s commitment to creating products with materials that benefit the world.

The driving force of sustainability in the brand’s 3D-printed luminaires lies in nine key elements to become truly circular. These include the use of recycled and bio-circular materials, a design approach that utilizes fewer components for enhanced flexibility, an on-demand production, and a focus on easy disassembly.

Actively engaging in closing the loop of recycling, the brand is piloting initiatives to prove the recyclability of luminaires and collaborating with organizations to collect and recycle its own End-of-Life luminaires. Likewise, Philips MyCreation prioritizes energy efficiency, durability, and reliability. Therefore, the company’s luminaires are part of the GreenSwitch program and are aligned with the “Lighting for Circularity” approach of Signify.

Furthermore, as Philips MyCreation continues to pioneer with its 3D-printed luminaires and its commitment to reducing waste, lowering carbon emissions, and creating products designed for circularity, DesignWanted will continue to share its vision of a sustainable future through a series of upcoming articles.