See inside the factory — Philips MyCreation unveils craftsmanship opportunities

Come with us as we explore how the brand turns waste into innovation to achieve a new standard in sustainable lighting.

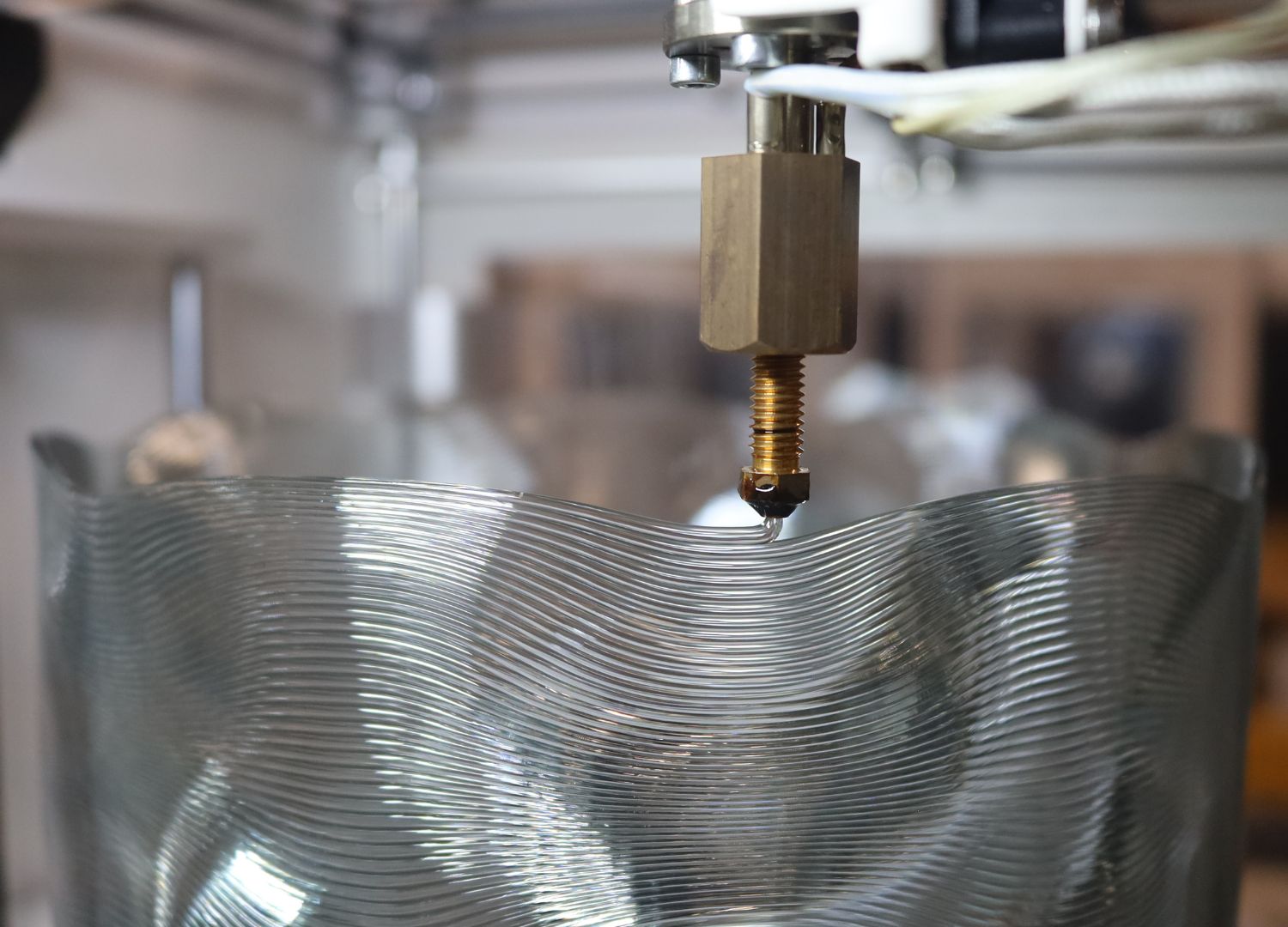

Acknowledging a growing emphasis on sustainability and personalization, Philips MyCreation is revolutionising the lighting industry by harnessing the power of 3D printing and recycled and bio-circular materials to craft unique designs. Rooted in a blend of cutting-edge technology and eco-conscious principles, the brand’s endeavour is driven by a synthesis of client demands for bespoke creations and MyCreation’s dedication to bio-circular and recycled materials. The result? Lighting solutions that are both distinctive and environmentally sound.

Central to the company’s philosophy is its unwavering commitment to social and economic sustainability, backed by an ISCC Plus certification for the bio-circular materials that spans its entire supply chain. From initial research and development stages to the final realisation, Philips MyCreation transforms sustainable materials into exquisite lighting fixtures that illuminate various spaces.

Philips MyCreation – Product Development Stages:

The Ideation Process

The creative journey begins with a simple design concept, nurtured to embody a specific aesthetic, lighting effect, or client specification. Drawing from insights gained through project briefs and collaborative ideation sessions, the design team in Eindhoven spearheads the conceptualization process, defining product families before crafting individual pieces.

“Many of our products are part of a larger family, thus we often try to define the family first and then the specific pieces within that family,” explains 3D printing development engineer Melle Grossl. Once the individual pieces are defined, Philips’ engineers start prototyping its first samples—a component Melle says is crucial in the Research & Development phase.

“A physical model sparks conversation among all disciplines, so we like to get mockups on the table on day one. Together with product managers we then rapidly work towards a final specification. In a couple of iteration cycles the mockups are transformed into final print codes, which can be tested in our factories before we release it to our customers.”

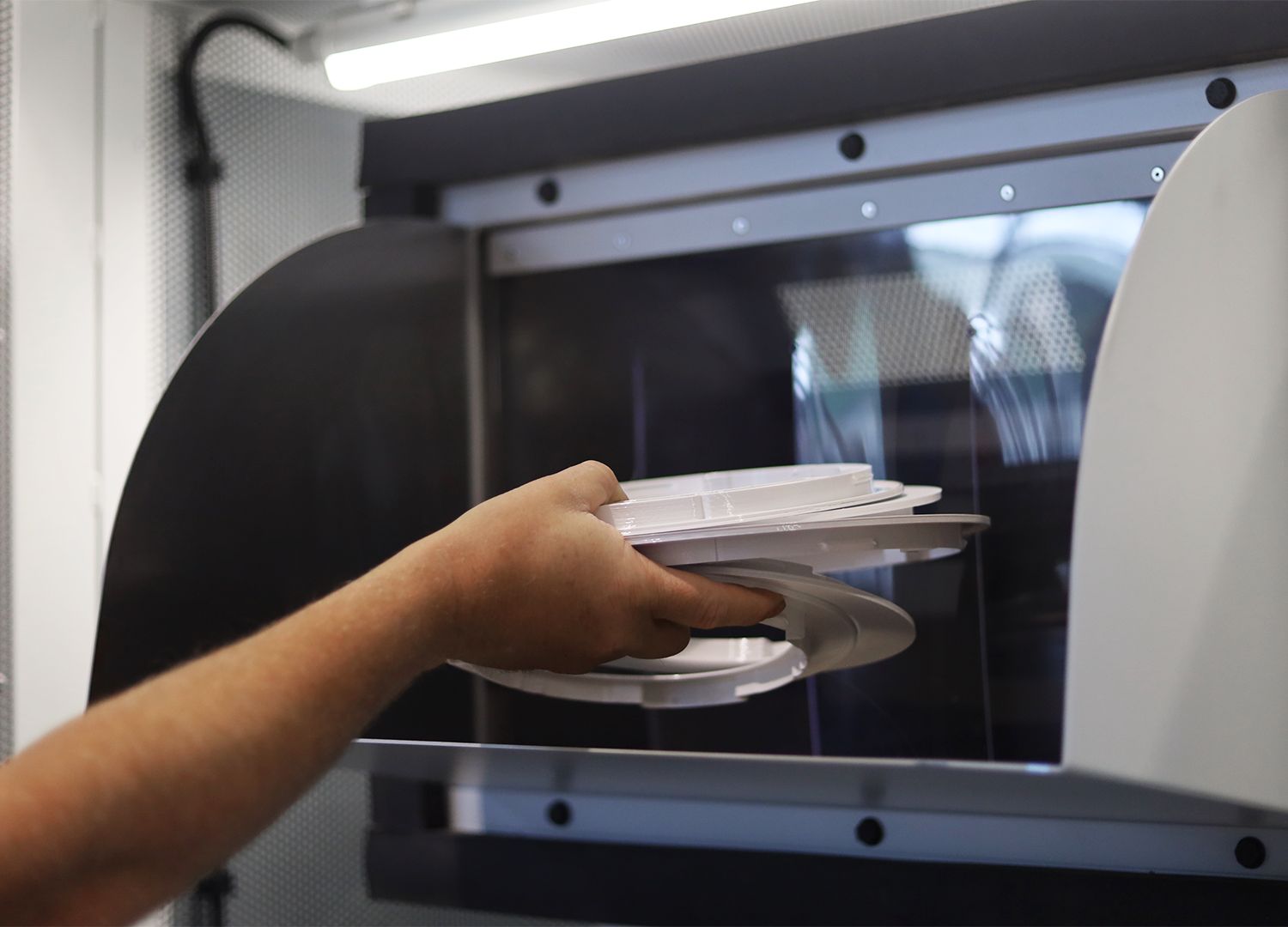

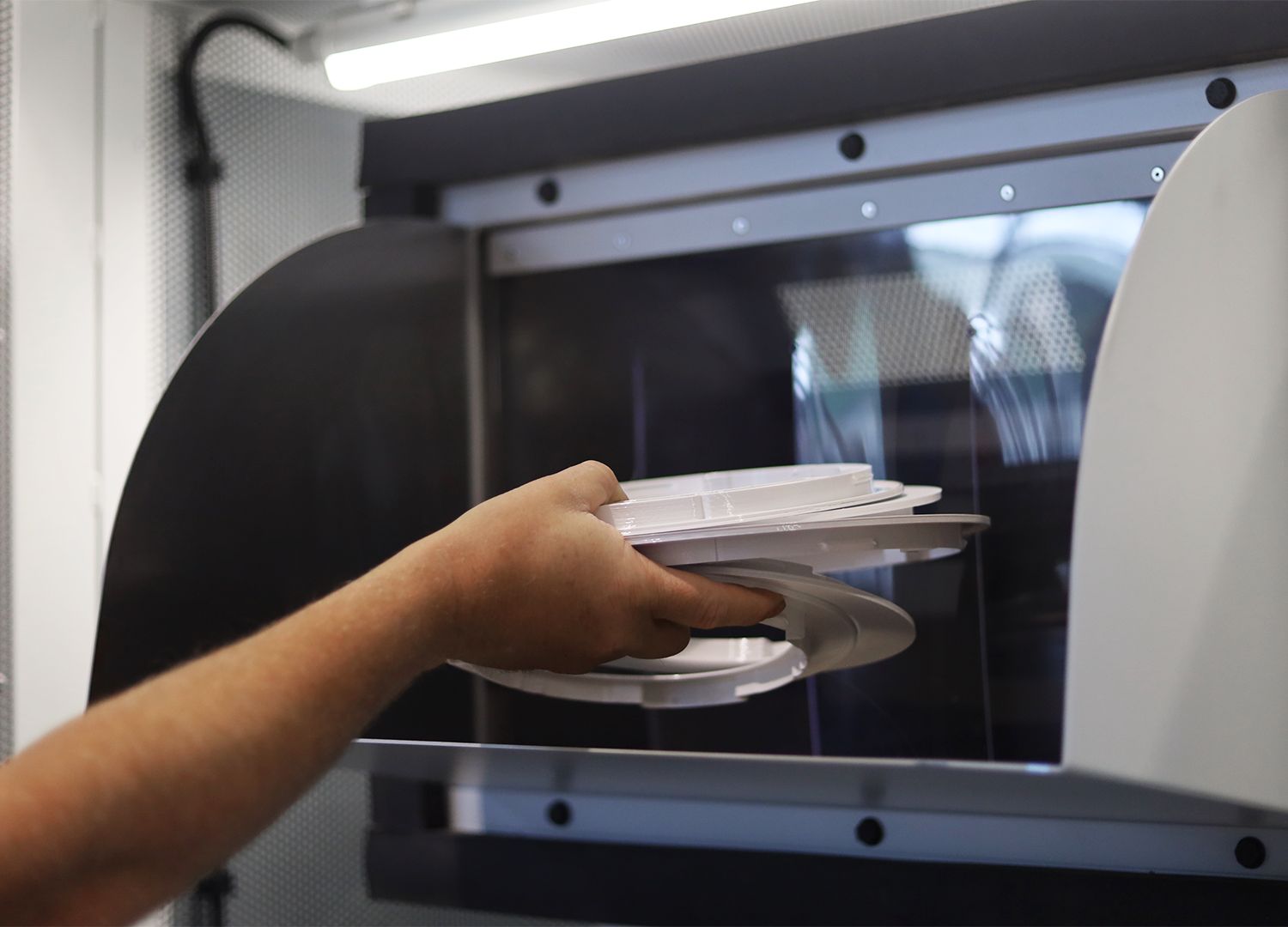

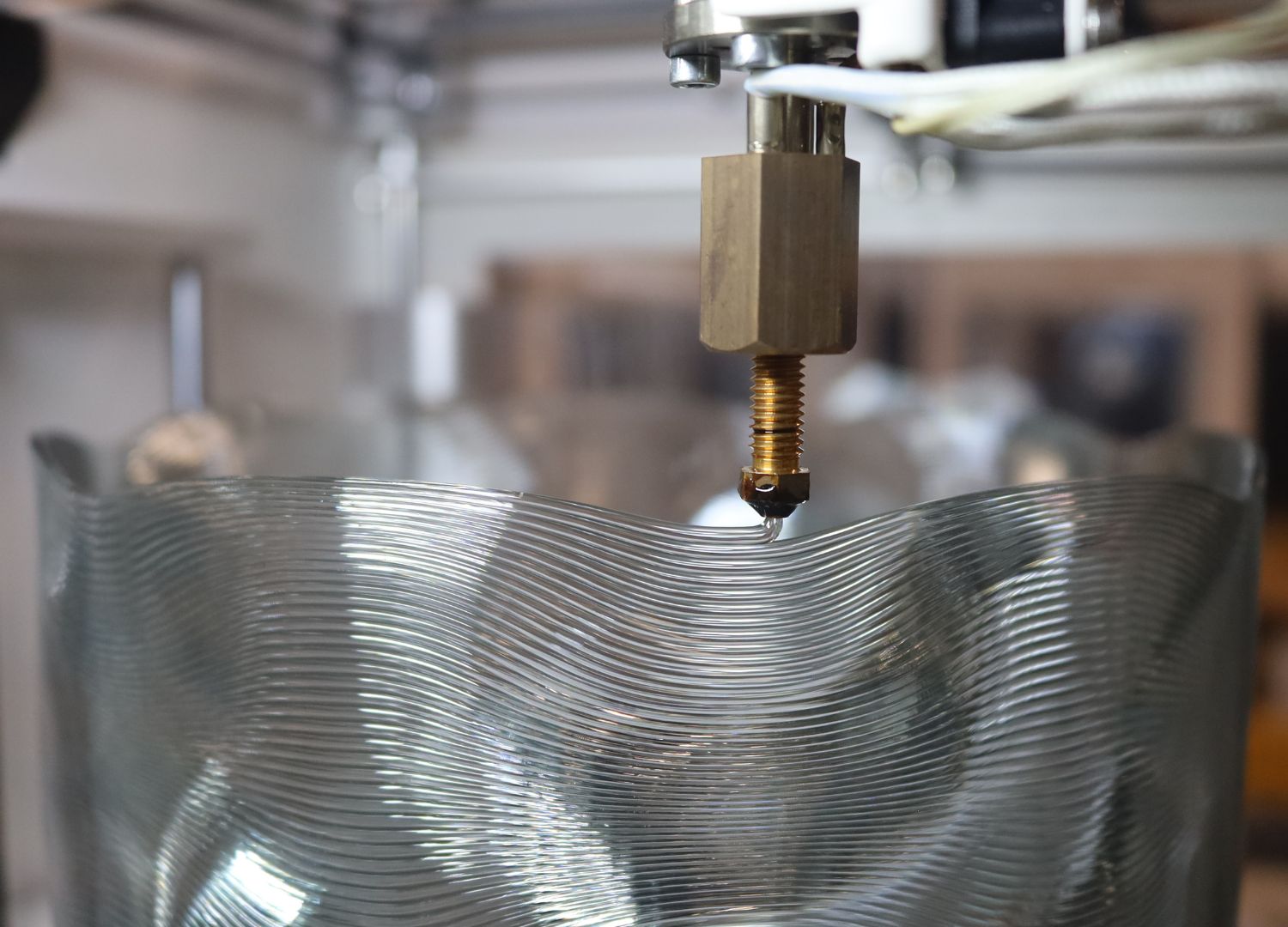

The design possibilities are almost limitless, the only constraints being those created by the 3D printing machines, which include both small and large sizes. Collaborating closely with technologists, the design team works tirelessly to navigate and optimise within the confines of each machine. In instances where larger pieces are desired, Philips MyCreation relies on a segmented approach, effectively building up the final product in multiple parts.

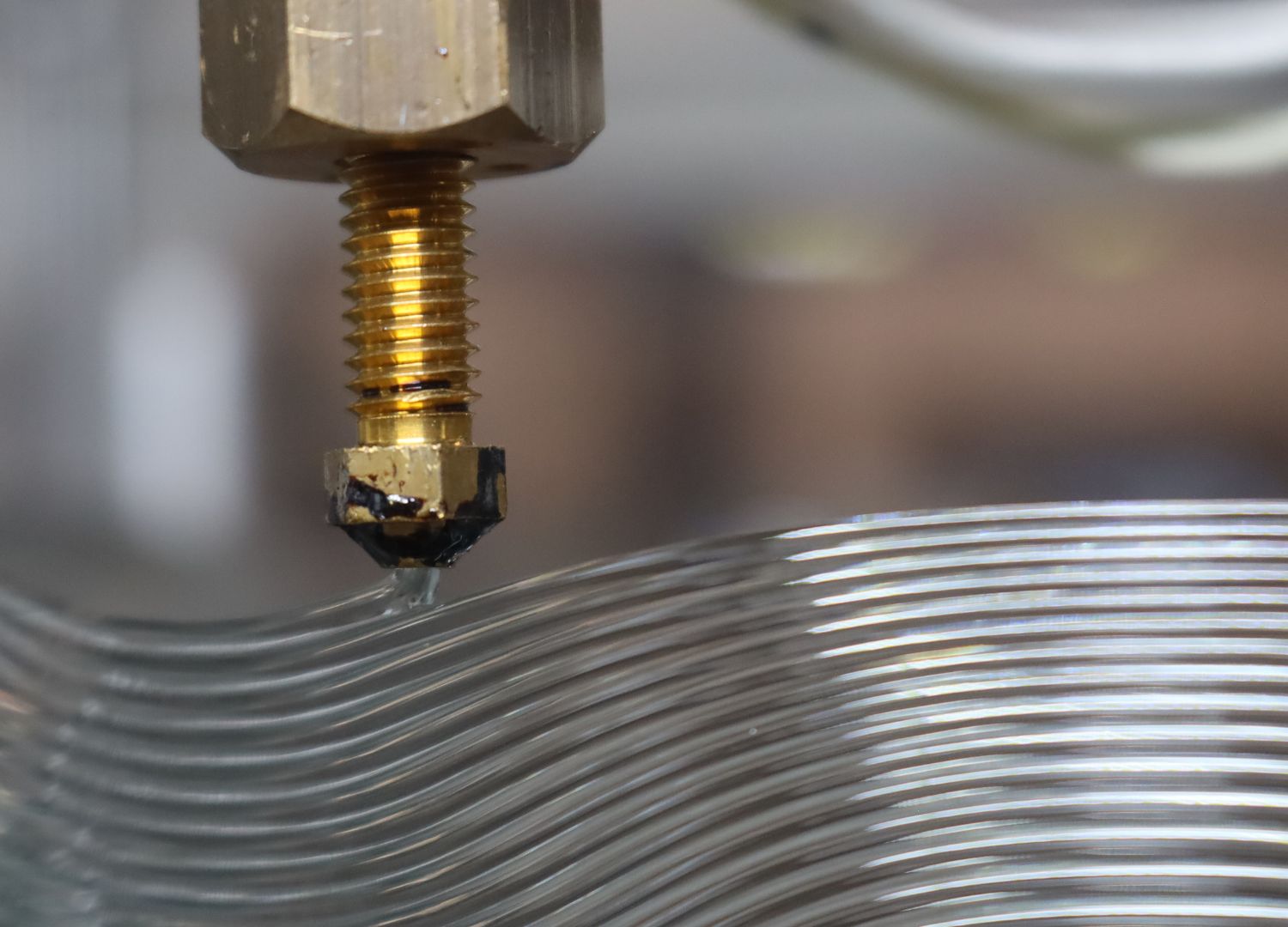

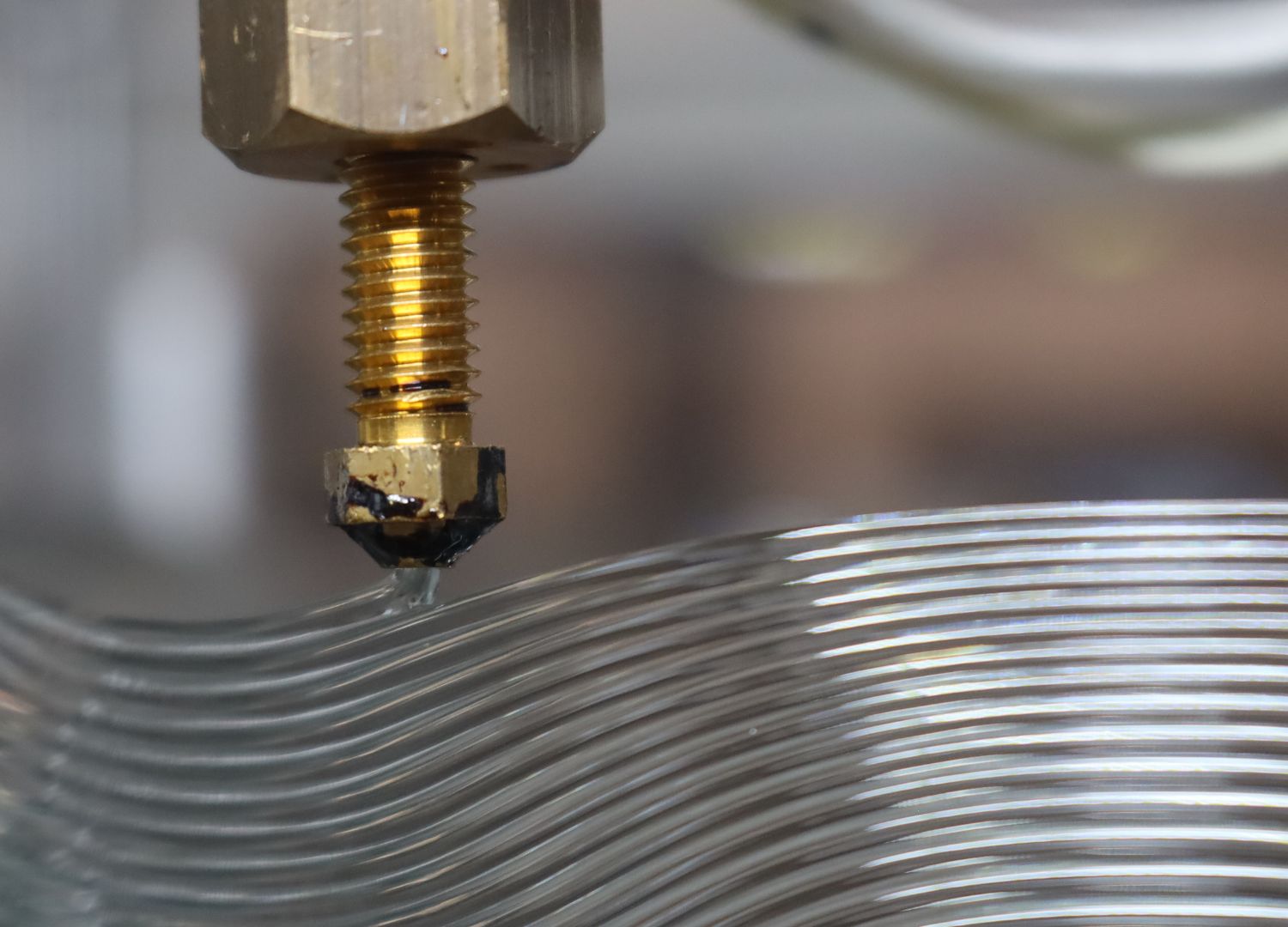

Defining the G-Code

When development finishes, the two teams work together to define a G-Code, which holds all of the relevant information for the 3D printers, including temperature and speed. This can then be deployed to the company’s global hubs, where identical machinery means each lighting design can be easily printed with the same quality, no matter where the factory is.

“Our printing system plays an important role in saving cost and energy by helping our operators streamline production, reducing machine idle time and waiting time between printing jobs,” explains 3D printing development engineer Peixin Wang. Digital Twin Technology accelerates this process, offering engineers a visual roadmap to swiftly identify and rectify potential defects. “By meticulously simulating each step, we can swiftly identify potential defects and fine-tune designs for optimal performance,” says Peixin.

Embracing an on-demand manufacturing model, the team can eschew traditional stockpiling practices, instead printing products locally upon receiving orders. This not only minimises energy consumption but also reduces costs associated with storage and transportation. Its lightweight products result in a lower carbon footprint and are designed to be easily disassembled, using no glue, no paint, no potting, and fewer screws.

Recycle + Renew

Meanwhile, printed parts can be recycled to create new designs, and the company is currently testing the viability of recycling its own printed materials from End-of-Life items to print new parts again. “Through standardised production procedures, we maintain tight control over yield and product quality, minimising waste and maximising efficiency throughout the manufacturing process,” adds Peixin.

Philips MyCreation strictly avoids using 100% virgin materials in the process and instead produces all printed parts with at least 55% post-consumer recycled, post-industrial recycled or bio-circular materials, which the company transforms into filament. It also collaborates with external filament producers to maintain a reliable supply.

“We print from reels with a fixed amount of raw filament, to get the most out of those reels we schedule every printed component in each colour in the best way possible to reduce the amount of residual filament,” says Melle. “Another benefit of 3D printing is the ability to print components on demand, using just the amount needed for an order without any overstock.”

In the Spring Oasis collection, for example, recycled water jugs commonly found in offices and homes are repurposed. This initiative not only helps reduce waste but also adds textures and colours reminiscent of the soothing qualities of water, seamlessly integrating nature into any space.

Final Execution

It only takes several minutes to 3D print a small pendant lamp, whilst larger items can take as little as several hours, helping to speed up the development of new products and materials. “Before introducing new materials into our portfolio, we can run tests quickly and find out how to make iterations and adapt the process to fit the new material properties,”

“Sometimes the new material might require a totally different printing setting – we might need to change the temperature, speed, or even the design itself. This remains the key challenge and differs case by case,” says Peixin.

One thing that remains consistent, however, is Philips MyCreation’s commitment to transparency and sustainability. This is exemplified by its creation of an Environmental Product Declaration (EPD) for each family, a standardised document that provides comprehensive information according to ISO 14025 standards about the environmental impact throughout its entire life cycle.

This includes the extraction of raw materials, manufacturing, distribution, use phase, and end-of-life disposal, with each EPD based on a thorough Life Cycle Assessment (LCA), which quantifies the environmental impacts associated with each stage of a product’s life cycle. By conducting LCAs and producing EPDs, ensures that its customers have access to clear and credible information about the environmental footprint of its products, empowering them to make informed choices that align with their sustainability goals.

“Here we include impacts based on material & manufacturing methods used, such as mining or the creation of components, the country of origin, and the weight, for example,” explains Melle. “Other factors include the characteristics of the production site, such as renewable energy used and water consumption, the efficiency and lifetime and the treatment after the useful product life.”

“Currently the product efficiency and lifetime as part of the “use phase” have the biggest impact. The second biggest impact that we can influence is the materials used.”

With this, Philips MyCreation has committed to creating products that minimise the overall impact in every other possible area of the production. In envisioning the future trajectory, the brand’s commitment to reshaping the lighting landscape through 3D printing and recycled materials emerges as a pioneering force. From the inception of a design idea to the deployment of Digital Twin Technology, the company consistently prioritises sustainability, transparency, and innovation.

When it comes to new development, they actively engage in co-creation projects with clients, particularly when there is a distinct emphasis on achieving specific lighting performance or desired aesthetics. In a recent strategic expansion, the company has also initiated collaborative ventures with external designers, marking a significant evolution in its approach to innovation.

The on-demand manufacturing model, coupled with a focus on sustainability, exemplifies the brand’s dedication to resource efficiency and eco-conscious practices. As the company actively engages in co-creation projects and collaborates with external designers, it propels itself towards an even more impactful role in sustainable design.