A device designed to upcycle discarded bottles into 3D printing filaments

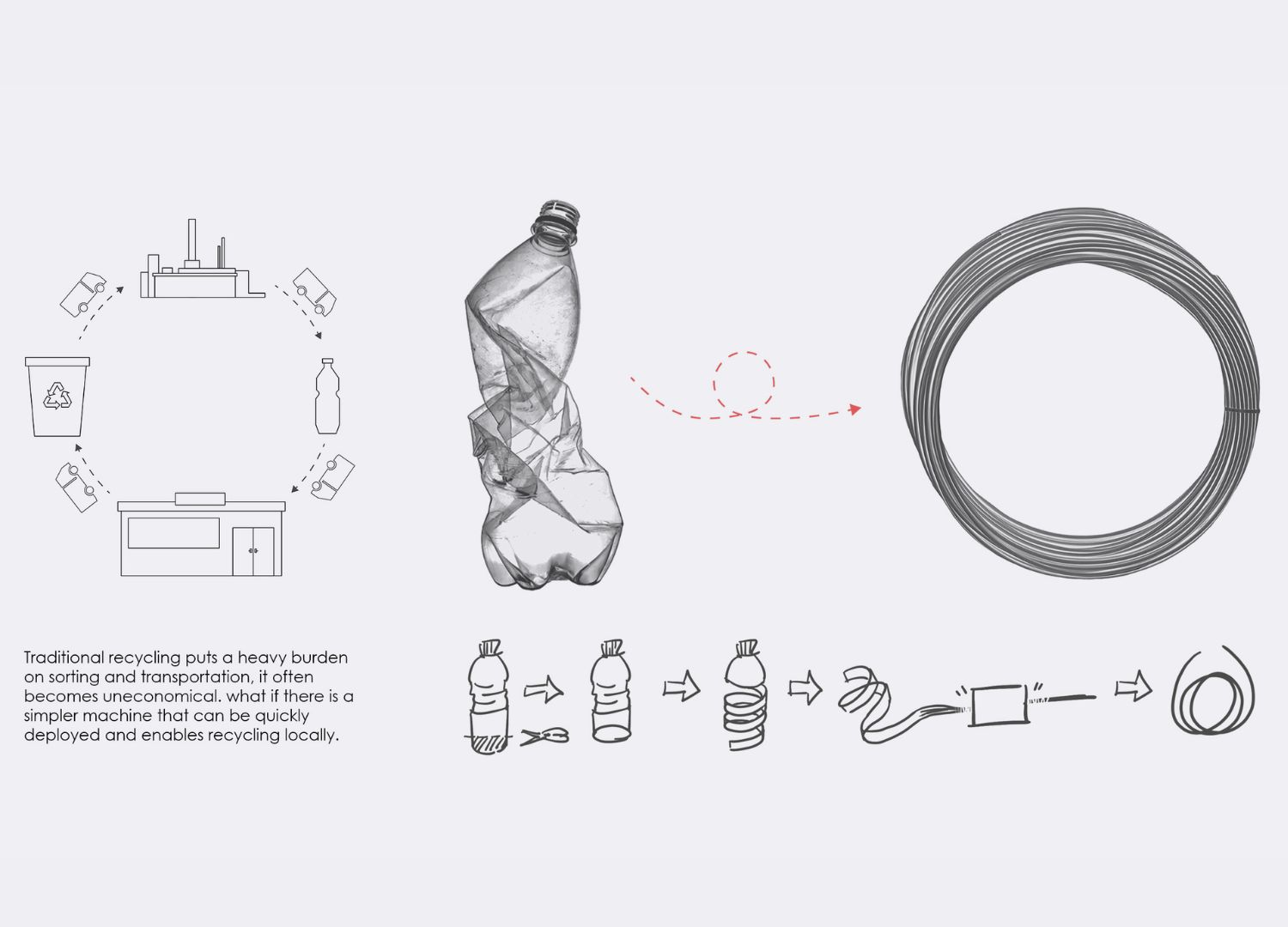

Traditional recycling necessitates multiple steps that often involve transporting materials over long distances. In contrast, Polyformer is a PET bottle recycling machine that can be constructed independently by anyone with access to a 3D printer

Polyformer by American designer Reiten Cheng emerges as one of the standout victors in the recent edition of IDEA, the International Design Excellence Awards, an annual event presented by the Industrial Designers Society of America (IDSA) during the International Design Conference (IDC) held in NYC.

Recycling PET bottles plays a pivotal role in advancing environmental sustainability. These bottles, widely employed for beverages and various consumer goods, carry a substantial ecological burden. The recycling process encompasses the collection of discarded PET bottles, their thorough cleaning and sorting, and subsequent conversion into valuable assets such as 3D printing filaments, textiles, and fresh PET containers.

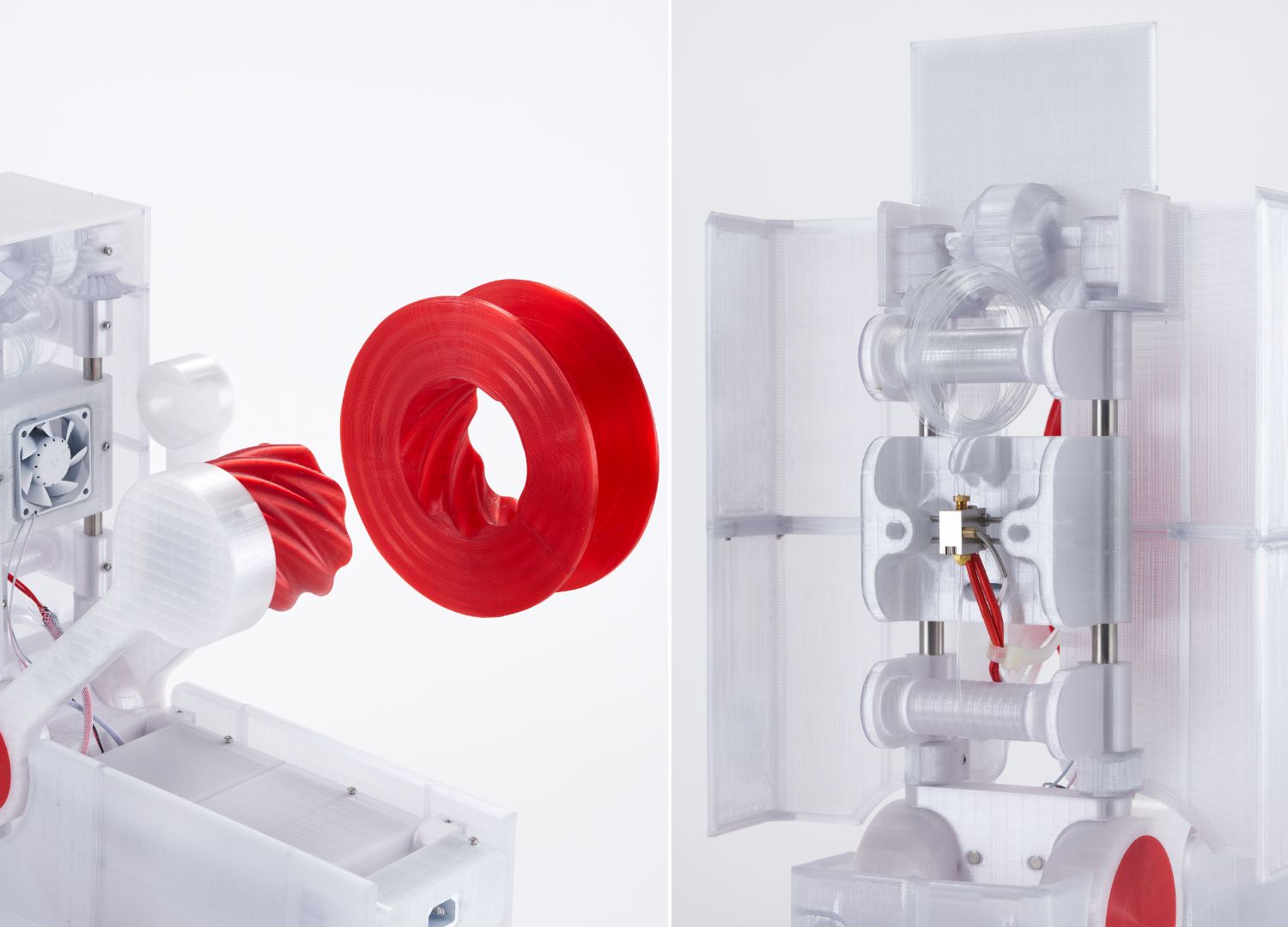

Beginning with the question, “What if PET bottles could be given a second life?” and confronted with the challenge of a seemingly inefficient process, Reiten Cheng conceived the idea for Polyformer: a remarkable 3D-printed, open-source machine that transforms ordinary PET water bottles into versatile filaments for 3D printers. This innovative solution offers an affordable and space-efficient alternative to traditional recycling methods.

This is how it works

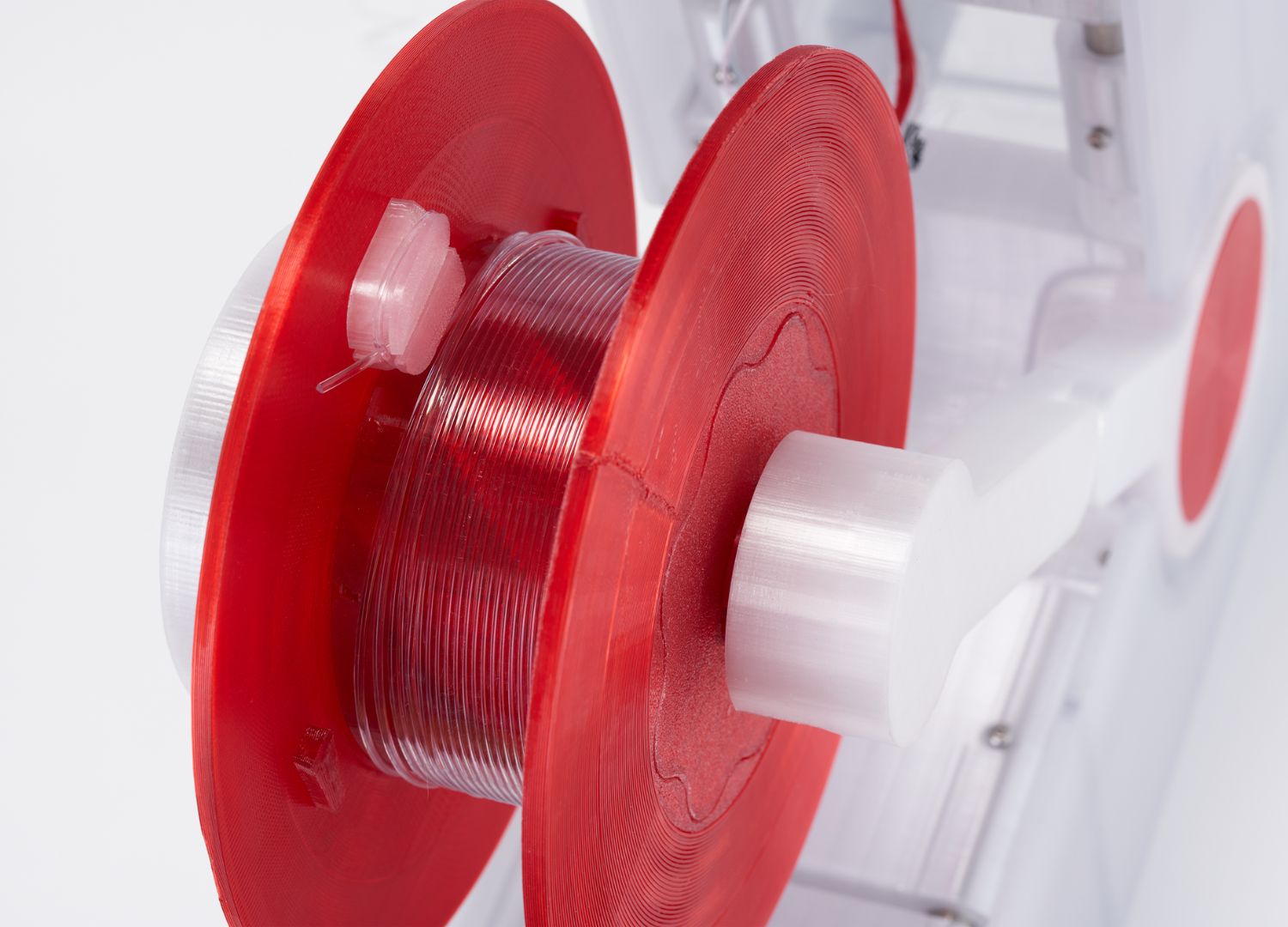

Polyformer employs a specialized slicing tool equipped with stacked bearings to precisely cut the water bottle into a continuous, uniform ribbon. This ribbon is then fed into the repurposed 3D printer hotend, where it undergoes thermoforming into a 1.75mm filament as it passes through a brass nozzle with a corresponding hole size.

The user can conveniently mount one end of the filament on the red motorized spool to automate the process. When needed, the spool can be easily removed and transferred for use on a 3D printer.

This solution simplifies the process of water bottle recycling, and it comes at a cost-effective price point of just $200. What’s more, it can be replicated with ease by makers in most countries, making it a compelling alternative to costly traditional recycling methods.

Targeting countries with fewer resources

As of now, over 300 Polyformers are in the process of being built across more than 50 countries, creating a vast and decentralized network of water bottle recycling points. These filaments are then used to produce essential items in various African countries.

Polyformer plays a pivotal role in recycling plastic bottles into 3D printer filaments, giving these bottles a second life by turning them into valuable products using FDM 3D printing technology. This is particularly beneficial in African nations where accessibility to such products is limited (a roll of filament costs as much as a month’s rent in Rwanda, but just as much as a simple lunch in some states).

What sets Polyformer apart is its user-friendly design, which relies on 3D-printed components and readily available 3D printer parts, making it the perfect tool for establishing decentralized recycling points.

A process involving collaboration

Reiten has already cultivated a community of more than 3,500 individuals in the course of 10 months. Their distinctive approach involves direct engagement with end-users, comprehending their challenges, making design adjustments to tackle these issues, and affording them the opportunity to test and refine the components.

This collaborative process accelerates product development and forges a meaningful relationship between the designer and the end-users, a rare phenomenon in traditional product development.

Polyformer: rooted in the concept of open-source

It is intentionally designed to be open-source, 3D printable, and user-assembled. It harnesses FDM 3D printing technology to achieve features that were previously challenging to attain. Thanks to the GPL3.0 open-source license, anyone can distribute, modify, and sell Polyformer, aligning perfectly with the project’s intended ethos. At present, there are two distributors offering Polyformer kits.

It is easily deployable in most countries worldwide, thanks to its 3D-printable design. It not only recycles plastic waste from water bottles, but also provides users with free materials for 3D printing, which can be transformed into various products and even more Polyformers.