The second life of PVB from automotive windshields

Exploring the innovative applications of Polyvinyl Butyral recovered from industrial waste and inspiring environmental conscious design.

Polyvinyl Butyral (PVB) is a resin typically used in the production of laminated safety glass, such as automotive windshields. Its primary role is to improve the glass resilience in case of impact, preventing shattering and ensuring passenger safety. However, when a vehicle reaches the end of its life, these windshields become a source of waste. With the rise of environmental consciousness, finding new strategies to recover PVB has become a focal point for many players trying to repurpose what was once waste into a resource for new products.

PVB material: pioneering sustainable design:

PVB’s properties

This plastic resin showcases quite interesting inherent properties, such as clarity, adhesion, toughness, and flexibility, making it a great candidate for recycling. It is these characteristics that have initially made it valuable in safety applications. At the end of its lifecycle, PVB can be reclaimed from windshields through a process of mechanical separation and subsequent purification. Notably, the recycled material retains many of the beneficial properties of the original PVB, making it suitable for repurposing in various industries.

What are the applications

The versatility of recycled PVB has opened up a broad spectrum of new applications. Companies are now utilizing this material in the creation of paints, foams, and new textile materials that serve as sustainable alternatives to leather (more innovative materials here). These applications not only reduce waste but also contribute to the development of products with an intrinsic lower environmental footprint.

Case studies in Product Design

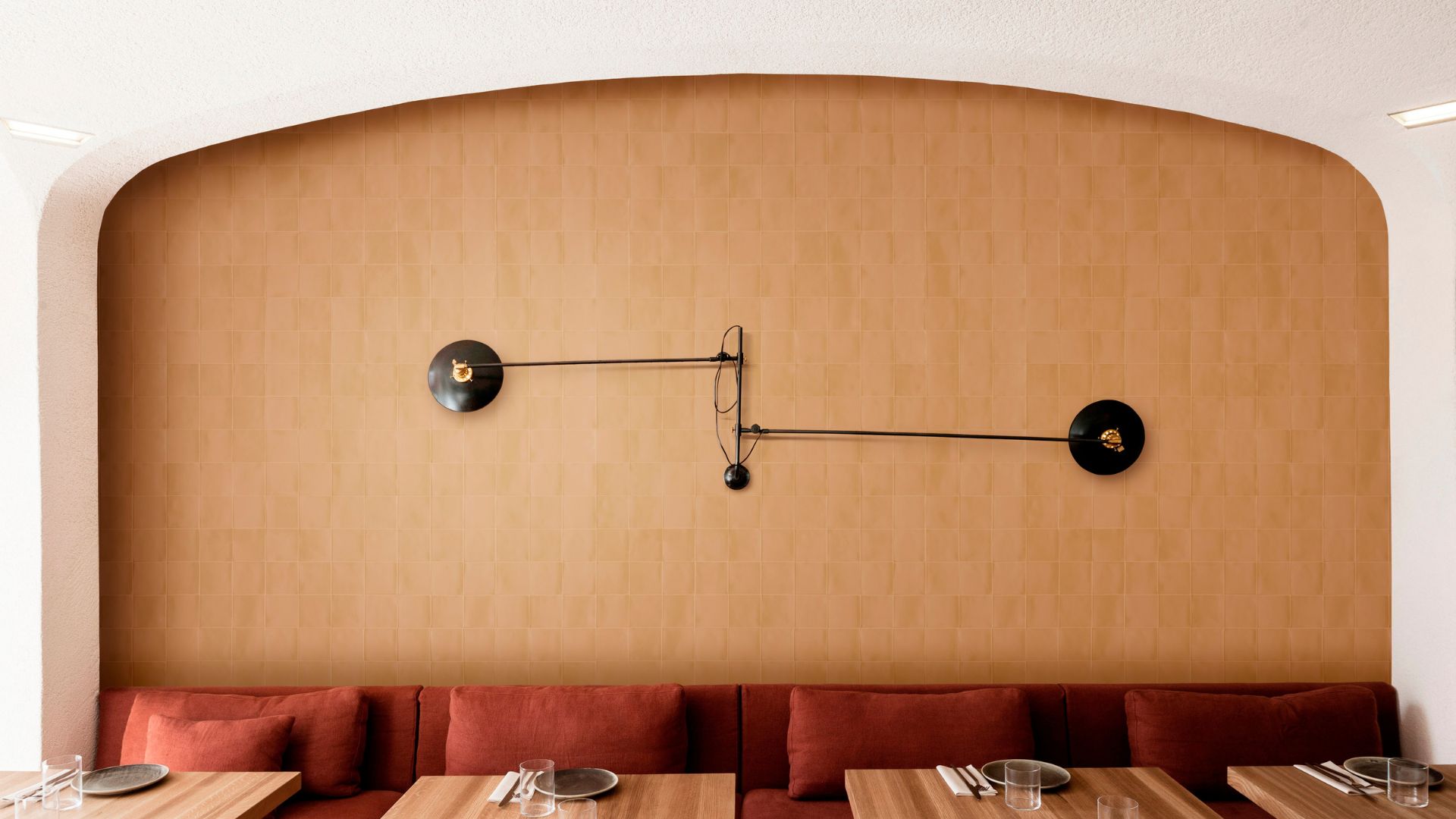

Several companies have pioneered the use of recycled PVB in final, commercial products. For instance, danish company Shark Solutions has developed recycled PVB dispersions for paints, that can be used as standalone binders or co-binders, to enhance the paint’s toughness, color fastness, flexibility, and elongation. Together with french based ID-Paris, they’ve developed and brought to market Peinture ECO RESPECTUEUSE, a wall paint for interior masonry decorations made of 50% recycled content.

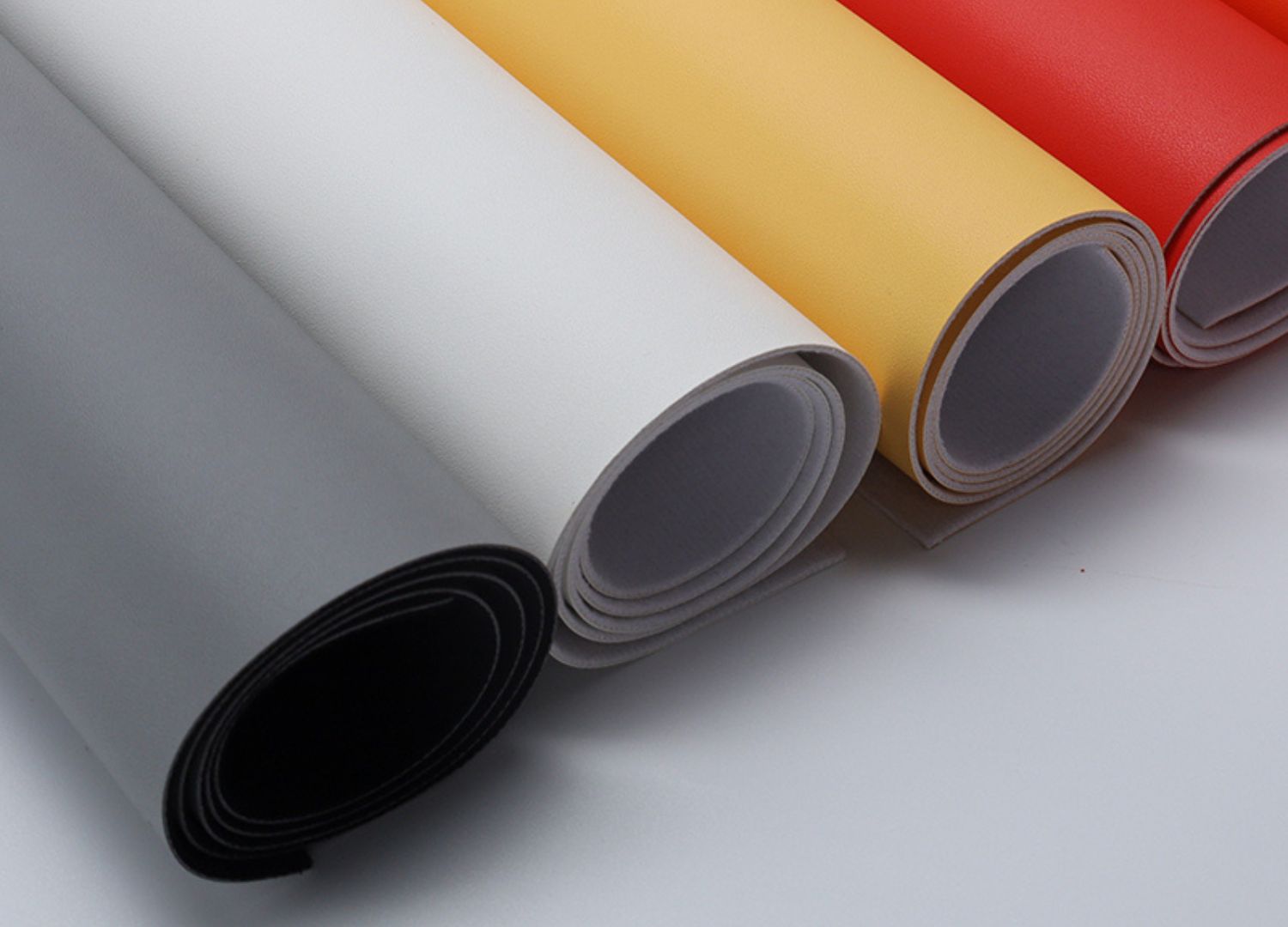

Another notable example is the manufacturing of coated fabrics using recycled PVB, which act as substitutes for leathers and other synthetic alternatives that are PVC or polyurethane-based. An interesting example of such a product is provided by Honor New Materials Co. Ltd, a China based company, that offers designers a wide range of colors and textures for customized product design made of r-PVB. The fabrics showcase interesting properties both aesthetically and in terms of performances, with a nice look and feel. The backing textile can be made of cotton canvas or of recycled synthetic fibers that are GRS certified.

The recycling of PVB from automotive windshields represents a significant technological strategy that addresses the impact of industrial waste originating from the automotive industry. By considering this valuable material, designers can reduce landfill waste, conserve resources, and create innovative products that meet the demands of environmentally conscious consumers. As technology and processes continue to evolve, the potential of this material solution will expand, paving the way for new applications and supporting the cause of sustainable development.