Telare la Materia: giving waste a new meaning, one fiber at a time

What if fashion waste never left the factory? Davide Balda transforms discarded fibers through material experimentation, forging a circular, site-specific alternative to global waste export.

We rarely pause to ask: what happens to the racks of unsold clothes in retail stores? Most of these garments aren’t recycled or responsibly disposed of in the countries where they’re produced. Instead, they’re shipped across continents – often to developing nations – where they overwhelm local waste systems and turn entire landscapes into sprawling open-air landfills.

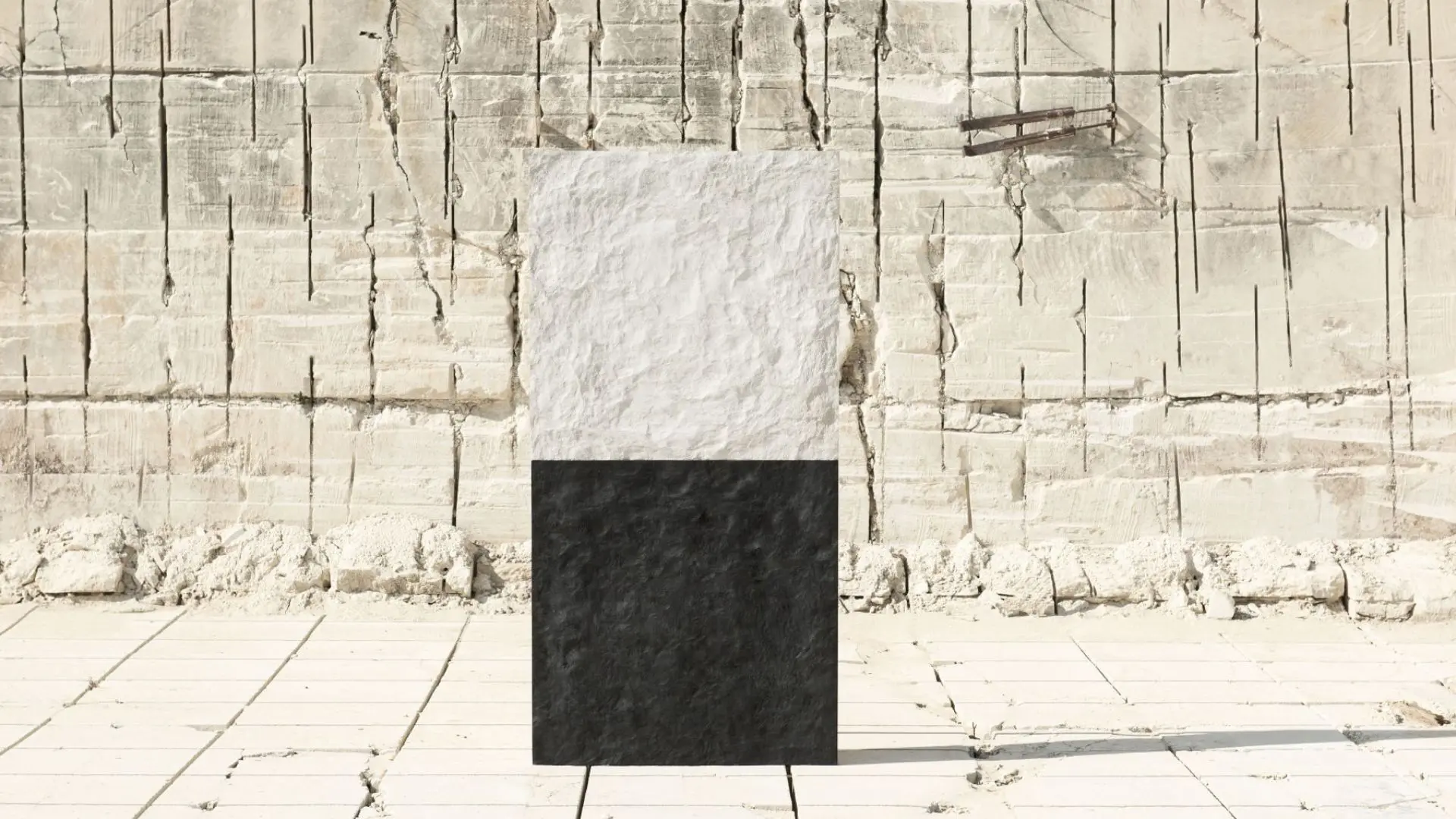

Telare la Materia, a project by multidisciplinary designer Davide Balda in collaboration with the Benetton Group, addresses this often-overlooked consequence of global fashion. Unveiled during Milan Design Week, the installation appeared in two locations: at Basic Village, as part of the Conscious Object exhibition, and in a storefront along Via Paolo Sarpi, in partnership with Arsonars.

Developed during Balda’s residency at Fabrica – Benetton’s research center – the project explores how textile production waste can be reduced and reprocessed through grinding into synthetic and organic fibers, which then serve as raw materials for new applications: Technosoil, Building Material and Nuno Felt. Rather than exporting waste, Telare la Materia proposes a radical shift – one that closes the loop locally and challenges the fashion industry to rethink both the scale and geography of its impact. We spoke directly with Davide Balda to learn more about his vision.

What need originally sparked the creation of ‘Telare la Materia’ project?

Davide Balda:

“It all began with a research into new methods and processes to counteract the environmental impact of the textile industry and promote the local disposal of production waste. Today, such waste is instead packaged and shipped through packages that in Swahili are called Mitumba, to non-European countries, such as Africa and South America. Telare la Materia proposes an alternative, scalable and replicable method of disposing of excess production generated by the textile industry”.

You explored three different applications for recycled textile fibers. Could you walk us through Tecnosuolo and explain how it works?

Davide Balda:

“Tecnosuolo offers an innovative and versatile method that allows agriculture to break away from fixed cultivation sites, enabling growing practices outside of traditional soil and land, according to individual needs. Using a hybrid approach that combines hydroponic and traditional techniques, vegetable and animal textile fibers – such as linen, cotton, wool, alpaca, and cashmere – are used both as a fertilizing substrate and as mulch, improving soil structure.

In mulching, these fibers cover the soil, increasing its compactness and resilience, allowing plants to thrive even in challenging conditions. This method offers a sustainable alternative to plastic mulch sheets, which release microplastics into the ground and are difficult to dispose of.

Thanks to their ability to absorb and retain more water than soil, these fabrics also serve as an effective substitute for peat in greenhouses and nurseries – reducing water use and supporting plant growth even in drought-prone areas. In this way, agriculture becomes a practice in motion: adaptable, mobile, and scalable across new and diverse environments”.

Could you also tell us more about the other two new applications, Building Material and Nuno Felt?

Davide Balda:

“Building Material explores sustainable solutions for green construction. In these material experiments, textile fibers of plant, animal and synthetic origin are combined with clay waste and a geopolymer base. The result is a composite made from production waste and natural materials, whose manufacturing requires little energy and does not harm the environment.

Nuno Felt is a unique material produced through the wet felting technique, using synthetic, plant-based and animal fibers. These are felted by hand with water and Marseille soap through a process of rubbing and massaging. Unlike traditional felts, this method enables all fiber types to be fully recycled without creating additional waste. The result is a fabric-like, artisanal material that can be used for fashion items, accessories and interior design. Thanks to its thermoregulatory and insulating properties, it can also be applied to interior walls to help stabilize indoor temperatures and reduce energy consumption”.

You describe yourself as an “archeodesigner”. What exactly does this mean to you?

Davide Balda:

“Archeodesigner is a compound word that merges archaeology and design. It means finding and designing with materials, understood as the rubble and residues of the contemporary world, in order to give them new life, functionality and meaning. A key part of my research is understanding the geographical origin of matter – tracing its formation through the place where it was found.

My interest in the Earth’s evolution and transformation led me to study a particular kind of fossil known as technofossils: the fossils of the future, the residues of natural and artificial origin that human activity has produced during the span of its existence on our planet. An archeodesigner, then, is like an excavator – someone who digs through the debris of the past. Their role is to reconstruct and describe history by digging among the Technofossils with which to create new materials or artifacts”.

Do you think the fashion industry is truly shifting toward circularity, or is there still a long way to go?

Davide Balda:

“An ecological conversion of production systems requires time to be developed and economic investments to be put into practice. Very often, large companies find it difficult to change their approach towards a circular and sustainable soul for various reasons, such as high costs of conversion of production methods, non-immediate results and lower generated earnings than the previous one. A thought that highlights how today’s companies base their business system on a capitalistic economy, poor in culture and human values.

By contrast, circularity in the fashion industry is being advanced by start-ups and small businesses. These actors are developing systems to revalue textile waste by focusing on the end-of-life phase of products and enabling their reuse in new ways. Two notable examples are Mercato Circolare and Atelier Riforma, whose RiVestiTO project uses an innovative system to collect and distribute textile waste, recovering unused materials through partnerships with large collection and donation centers. Through an online platform, public and private textile entities can upload and share their production waste, fostering new potential uses for these materials”.