An innovative strategy to recycle unused cigarette filters

Rezero gives pre-consumer cigarette filters a second life, reducing environmental impact while delivering high-performance material solutions.

This Irish start-up Rezero develops material solutions by recovering pre-consumer cigarette filters made of cellulose acetate, giving them a second life. The company has developed an innovative strategy to value a material that would otherwise be incinerated, achieving mechanical performance and aesthetic qualities for product design comparable to those made of virgin acetate.

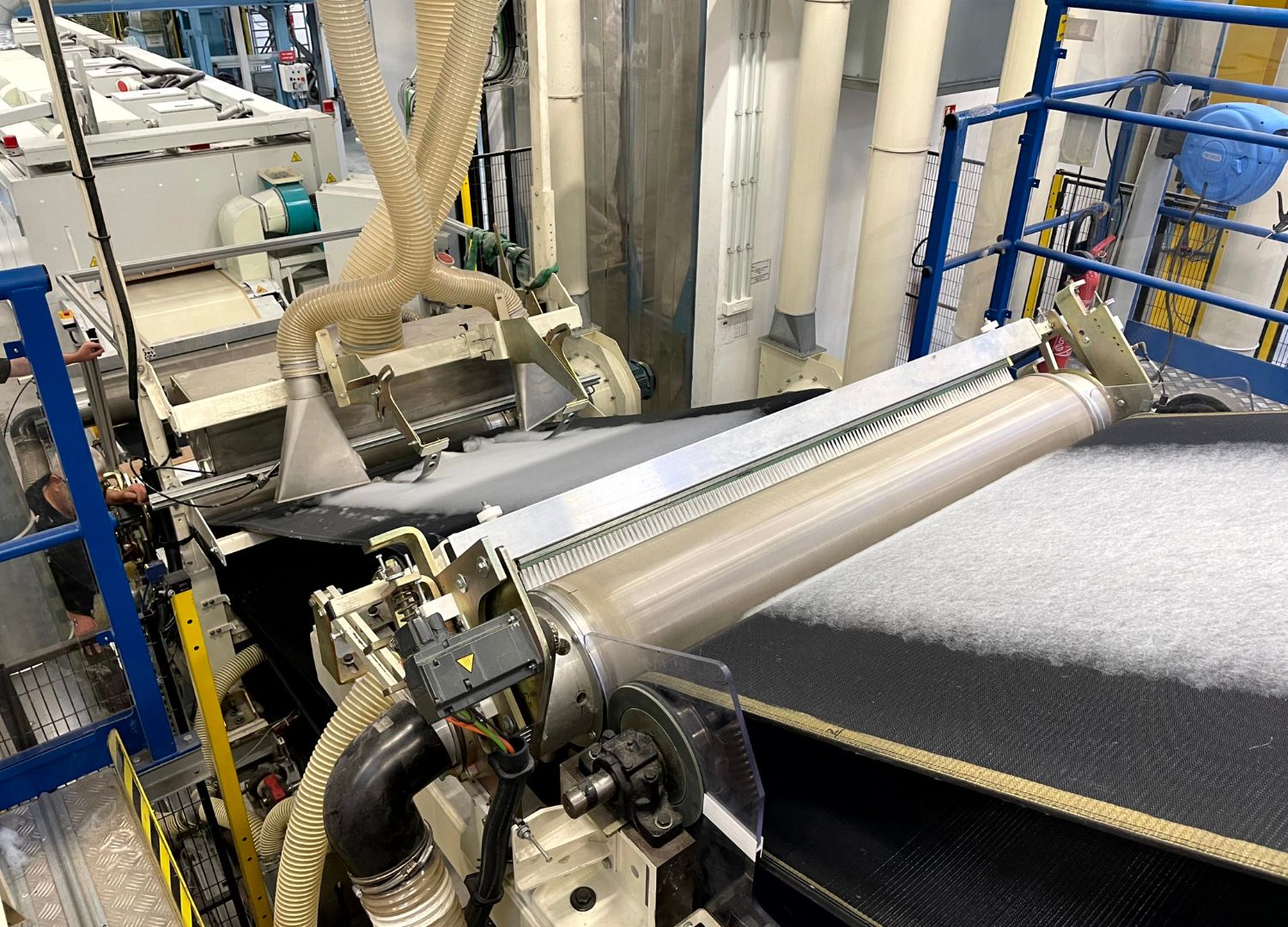

Depending on the targeted material output, the transformation process follows two distinct pathways, resulting either in Re-fil® fibers or in pellets obtained through filter shredding followed by compounding with plasticizers and pigments. The facility also offers a sheet format, in which the fibers are isolated and subsequently converted into sheets.

Gallery

Open full width

Open full width

The material can be applied across different sectors. The fibers, for example, can be used as-is for sound absorption panels, padding/wadding, filtration. The pellets are versatile for injection molding, enabling the creation of fashion items such as small parts and hardware components. Finally, the sheets are ideal for crafting eyewear frames, accessories, and custom-cut designs.

Some applications of these materials include sunglasses – soon to be launched – as well as buttons of various shapes and colors produced from pellets using solar-powered processes. While the company’s primary goal is to replace as much virgin acetate as possible in the fashion industry with recycled acetate, a wide range of products beyond the fashion sector, requiring specific functional performance properties such as liquid filtration, can also be developed.

Right now, the transformation process can only be applied to pre-consumer filters, as the high costs required to clean and treat post-consumer filters – necessary to make them safe for recycling into new products – limit their applicability. The raw material is mainly sourced from customs seizures or manufacturing waste. The start-up is currently working on scaling up material production.

The process enables a fully European production chain, in contrast to conventional acetate, of which around 80% of the global supply is produced outside the European Union. This recycling technology therefore represents an industrial path capable of delivering high-performance materials with a reduced environmental impact.