We (finally) get to build the right way

Disruptive Chilean tech company Strong by Form’s sustainable ultralight high-performance timber-based biocomposites can substitute concrete, aluminum, and steel.

Choosing to challenge tradition is oftentimes deemed heroic but, in this case, it was unignorable urgency rather than emotional sentiment that prompted the team behind Strong by Form to roll up their sleeves and get to work. According to a recent report by Plan Be Eco, the construction sector is responsible for approximately 38% of global CO2 emissions, with 28% from building operations and 10% from the construction industry itself.

Instead of nurturing abstract ideas, the company chose to go back to the basics by focusing on the efficiency and intelligence of the oldest living thing on earth–trees. As high-performing structures, trees withstand acute wind and snow stresses just by having the right form, density, and fiber orientation. Strong by Form’s design-to-manufacturing technology implements the natural structural finesse of trees to engineered wood constructions. Their cutting-edge approach comprises digital design, structural optimization, and digital fabrication to develop and produce composite parts.

Founded in 2018 and based in Chile, Strong by Form’s ambitious venture is led by experts. CEO Andrés Mitnik Asun is a Harvard and NYU graduate. As a civil engineer, he specializes in technology innovation. Architects Daniel Ortiz del Río and Jorge Christie Remy-Maillet act as CTO and CPO respectively. While del Rio serves as a Digital Fabrication advisor, Remy-Mallet contributes with his knowledge of business operations and robot programming. Their goal of making wood-based sustainable composites cost-competitive and adopted on a mainstream level by the majority of stakeholders in the construction industry is driven by Woodflow.

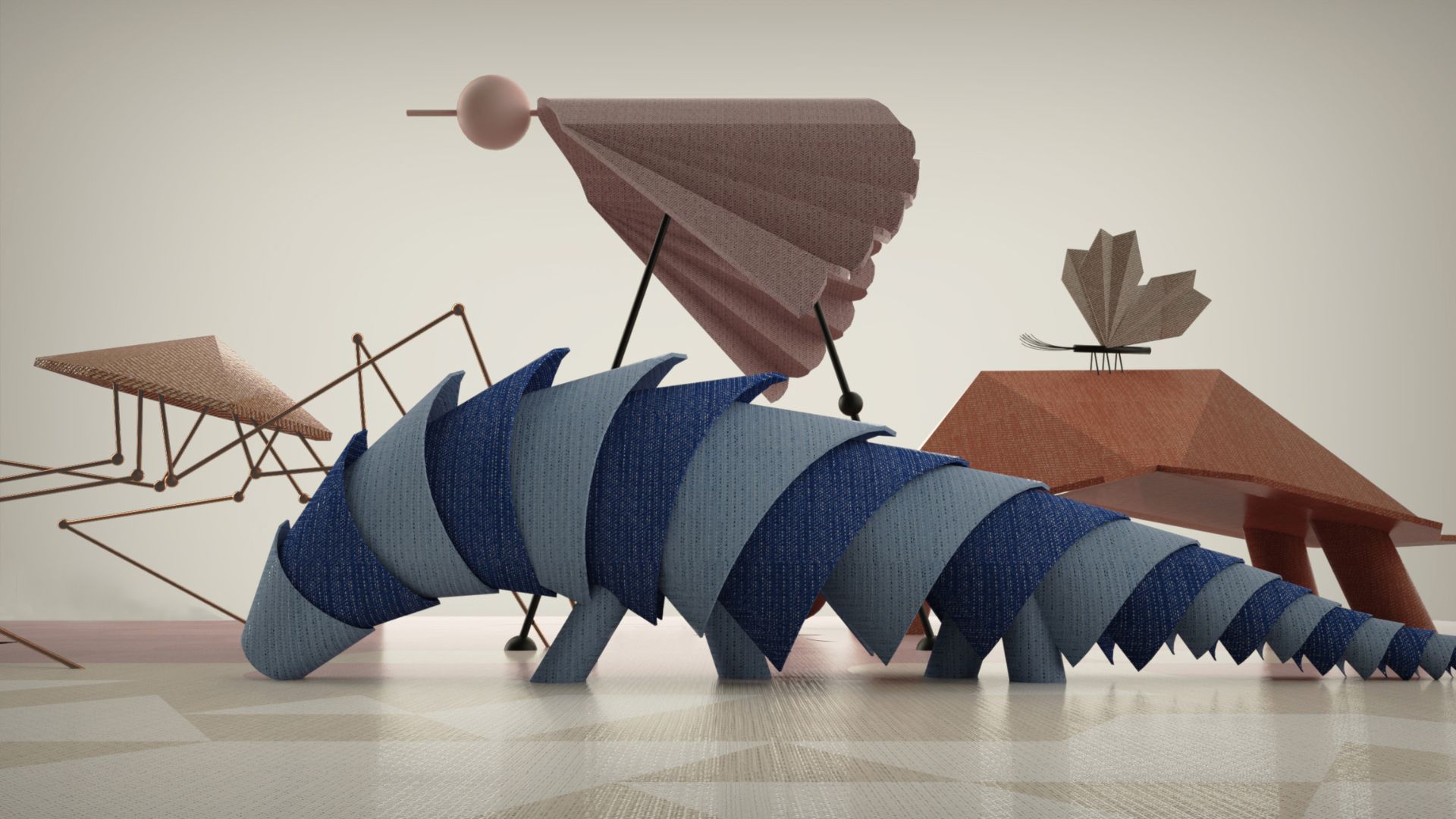

– © Strong by Form

As its name implies, Woodflow, an advanced software technology, stems from the concept of continuous, free-form motion. Using wood strands, with Woodflow, lightweight composite parts can be customized in terms of their shape and material architecture. The software allows for the integration of computational design, and structural optimization as well as identifying the right density, fiber orientation, and thickness that each component requires.

During production, Strong by Form achieves consistent quality and the highest level of performance while generating minimum amounts of waste–and, most importantly, using up to 90% of the tree as a structural component compared to the normally achieved 60%. The process is fully automated from beginning to end. The sustainable stress-tailored structural parts can replace highly polluting materials such as concrete, aluminum, and steel. Woodflow can be applied to vehicle body parts, lightweight construction, freeform concrete formwork, maritime structures, furniture structures, and more.

Strong by Form showcased their inaugural structural project, the very first Woodflow Weather Cabin, in Berlin’s Südkreuz in September of this year. The innovative construction made for Deutsche Bahn in collaboration with DB mindbox is characterized by its elegant exterior and hyper-efficiency. Using industrial wood water components, the cabin was made by combining Woodflox shells with stiff nodes. More recently, it was announced that Strong by Form is working with BMW to create an interior and exterior component, Woodflow skin coating, for the body of a 2024 model. As a pioneer, it’s safe to say that it’s only just the beginning for Strong by Form as a company not only contributing to but helping build a sustainable future.