The OTO Chair: how to move from an idea to a circular brand

KEY TAKEAWAY:

To turn a prototype into a product and a product into a brand you need a strong story but also great clarity in conveying its value. Alessandro Stabile and Martinelli Venezia did it with their OTO Chair

In 2019, Alessandro Stabile and Martinelli Venezia Studio created OTO, aka 1:1, one to one: a plastic injection molding chair, printed using recycled industrial plastic, lightweight yet sturdy, and delivered flat-packed, with all elements to be easily assembled by the user with no tools.

When it was first presented,

OTO was a good prototype. Four years later, it has turned into an actual circular business,

created and run by two design studios starting from that original product design idea and officially launching at the Milan Design Week 2023. Obviously, with the support of an investor.

How did this happen? What should a concept have, in terms of features and qualities, to make it as the starting point for a business?

1. A strong story

The story that OTO tells is simple, clear and strong: it’s not (just) the material you use that makes a product sustainable but the way it’s designed, produced, built, shipped, eventually recycled.

The OTO project developed from the choice of plastic: Martinelli Venezia and Alessandro Stabile wanted designers reevaluate plastic and convey the message that it is not the material itself that is the real problem, but the use we make of it.

We are all drawn to consider “sustainable” the objects that are communicated with labels such as “bio”; “green”; “plastic free” etc., dwelling only on the material used.

But the reality is quite different, because an object, to be truly sustainable, must be designed and built for circularity: minimizing the use of resources (during production, shipment, use), conceived to last and to be easily assembled and disassembled for recycling.

For their part, in order to avoid further production of unnecessary material, the designers decided to use industrial recycled plastic. And to link their business to an Italian start up called Ogyre that collects plastic from the seas. One part of earnings from the sales of OTO go to Ogyre: 1kg of marine waste will be collected for two OTO chairs sold.

[ Read also You are a 3D printing wizard: how do you build a circular company from here? ]

2. A lean, clever design

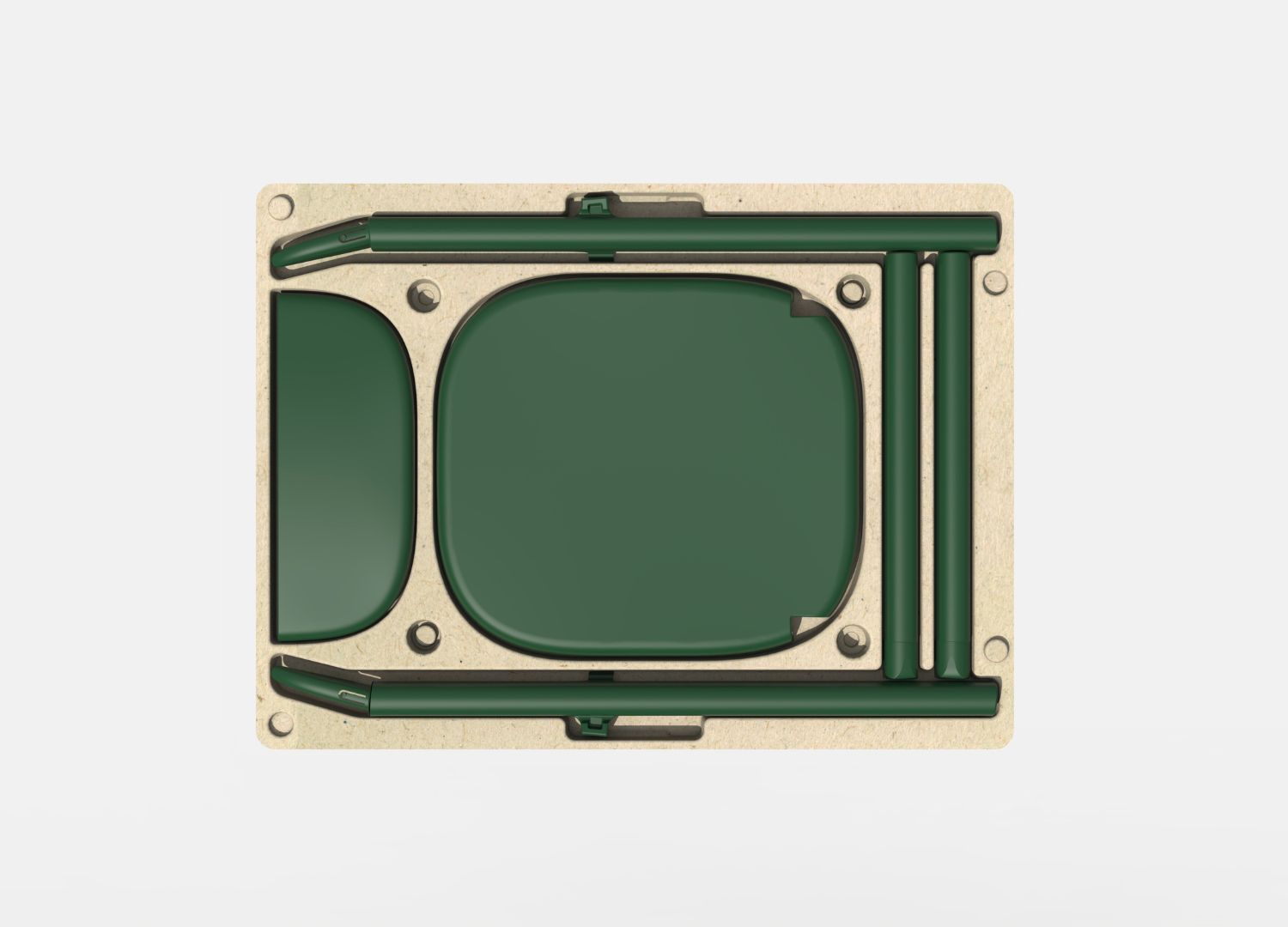

The design idea of OTO is very clear: making a chair out of elements that require assembly and that come out all together from a single, small mold.

The concept at the basis of the OTO chair – where its name One To One comes from – comes from scale models: the miniature objects made of plastic pieces that kids used to play with, and assemble.

Very much in vogue in the past, they were designed for age groups and made in different sizes. However, their real peculiarity lay in the pieces that made them up, which were anchored to a plastic grid with connections that needed to be broken to assemble them.

Alessandro Stabile and Martinelli Venezia took the grid concept from these miniature models: the original chair was to be printed in one element that would later be dismounted in different pieces. During the development of the mold, though, the grid became brittle and also resulted in a waste of plastic.

For these reasons, the design was changed to eliminate the joining elements.

The arrangement of the chair pieces in the mold remained the same, though: the elements of the chair come out in one single block of plastic.

3. A clear communication of the features and the search for an emotional bond

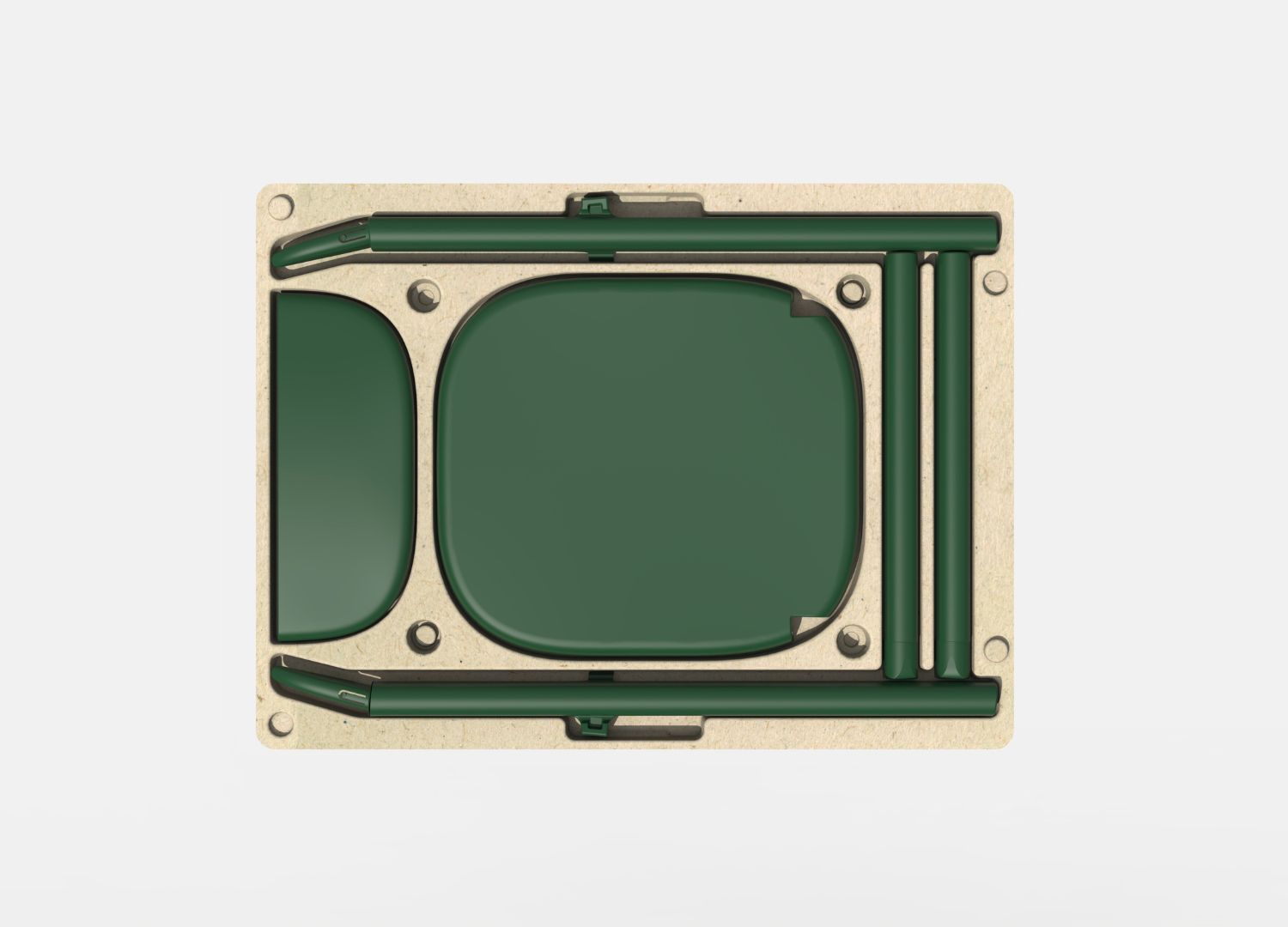

The main quality of the chair is mirrored in the packaging which is made of recycled pulp.

In order to be impactful and clarify the product and the production features, Alessandro Stabile and Martinelli Venezia decided to imprint them on the pulp packaging too.

This is also another feature that comes from the memory of the fun that they used to have when trying to assemble the miniature models which the designers tried to recapture, hoping that those who buy it will be able to create an emotional bond with the One To One.

4. A cost-effective (and green) production process

So, since the chair was just a concept a few things have changed, but not its basic principles.

Through working on streamlining forms and following the “miniature” concept, Alessandro Stabile and Martinelli Venezia were able to make a mold that uses 1/3 less steel than a normal chair made with the polyurethane foam technique.

In addition, the chair is designed to have no metal inserts, which means that less material is used to produce it; therefore, there will be lower costs and less wasted energy to produce it.

To make the chair feasible, the designers turned to the mold design company Secostampi, thus solving some technical issues that had not been considered.

[ Reas also Juggling management and creativity in a large design studio ]

5. A compact product perfect for online sales

The final structure of the chair includes: rear legs, which fit inside the backrest and attach to the seat; front legs are inserted under the latter; and, to make the seat strong, there is a large X.

The measurements, which refer to the arrangement of the chair in the packaging, are only 790x590x62 mm; this means it takes up little space.

In fact, suffice it to say that 33 stacked chairs fit in one cubic meter, which makes it easier to transport them; what is really interesting is that this mostly implies less CO2 dispersed into the air.

As for distribution, the designers have opted to trade exclusively online, in order to avoid unnecessary movements of the product; in fact, usually the product that leaves the factory is transported to stores and then later to the recipient.

6. An affordable price

The product, however, aims not only to be durable, of good quality, and sustainable, but also wants to be democratic.

The design was specifically conceived to contain costs (as well as emission) and to be able to bring it to the market, only through online sales, as a direct shipment from the production site to the final user.

Each OTO Chair (that will be for sale here) will thus costs 99€, including a donation to Ogyre that for each chair that is sold collects half a kilo of marine waste. The nice touch is: the buyers will be able to track the waste that is recovered thanks to their contribution.

7. Finding investors

The most important step, however, was to find investors who believed in the project as much as the designers themselves.

Two years ago, only after arriving at what could be called the final product, they decided to publish it as an industrial research project, hoping it would be noticed and put into production.

Thanks to all the points that we underlined above, and above all the product transparency (its peculiar characteristic compared to other products that are green and durable only in words), Alessandro Stabile and Martinelli Venezia managed to find an investor.

His name is Alex Pecoraro, an entrepreneur from the Veneto area in Italy who invests in environmental projects and who believed in the OTO idea.

8. Scaling up

Investors only come in if projects can be scaled. So Pecoraro’s first move was to turn the prototype not just in a product but in an actual brand.

The brand is called One To One, which, however, takes on a different connotation than the one thought up by the designers stemming from the scale model: in this case, the name refers to the interaction between the object and the consumer, trying to best meet the latter’s needs.

Starting this year, the chair will finally be available on the market and before that exhibited at Fuorisalone in Alcova together with a video installation by NonFuturo that illustrates its design process; it will also be possible to use it as it will be arranged in various places within the structure.

And, of course, other projects, not yet defined, will be realized by the two studios under the brand name One To One. More furniture and more, which will remain, however, always linked to the principles that were the basis of this first project of theirs, which took on the role of the brand’s manifesto.