Materials crafting the future of Sustainable Design thanks to biocomposite technology

Initially developed for uses in specific sectors such as automotive and aviation, today the emergence of natural fiber reinforced composites driven by sustainability concerns has also led to the creation of new patterns and aesthetic trends, broadening their potential field of applications.

Founded with a clear vision to reduce the carbon footprint of plastic production, Trifilon has emerged as one of the leaders in the development of biocomposites, helping to lower the environmental footprint of consumer goods with the use of high-performing materials.

Fiber reinforced plastics (FRP), also known as fiber reinforced polymers, are composite materials that have revolutionized product design across various industries. Traditionally composed of a polymer matrix reinforced with fibers such as glass, carbon, or aramid, FRPs offer superior strength-to-weight ratios, making them ideal for applications where lightweight and high strength are crucial.

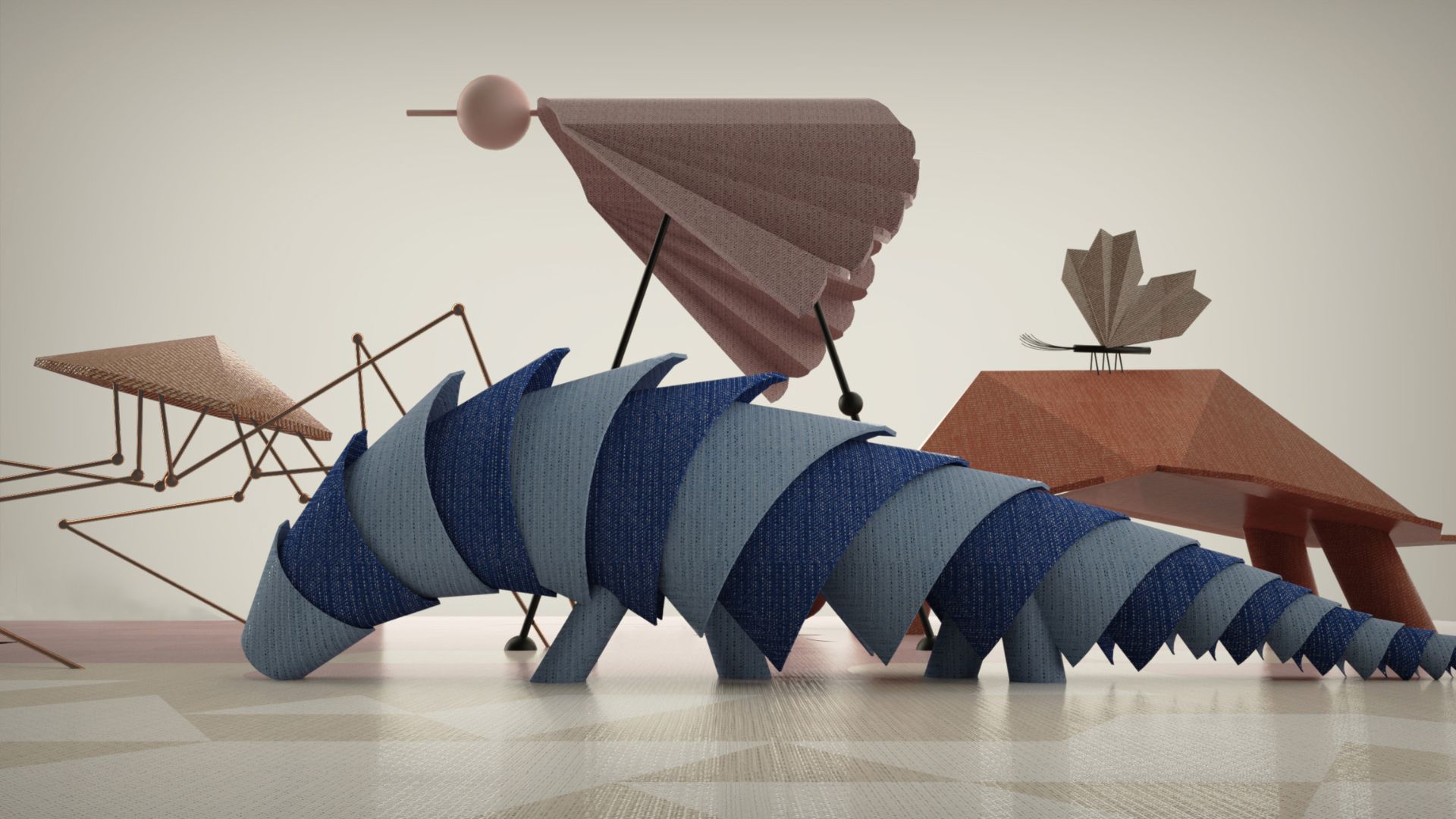

Initially developed for uses in specific sectors such as automotive and aviation, today the emergence of natural fiber reinforced composites driven by sustainability concerns has also led to the creation of new patterns and aesthetic trends, broadening their potential field of applications.

Trifilon’s material solutions

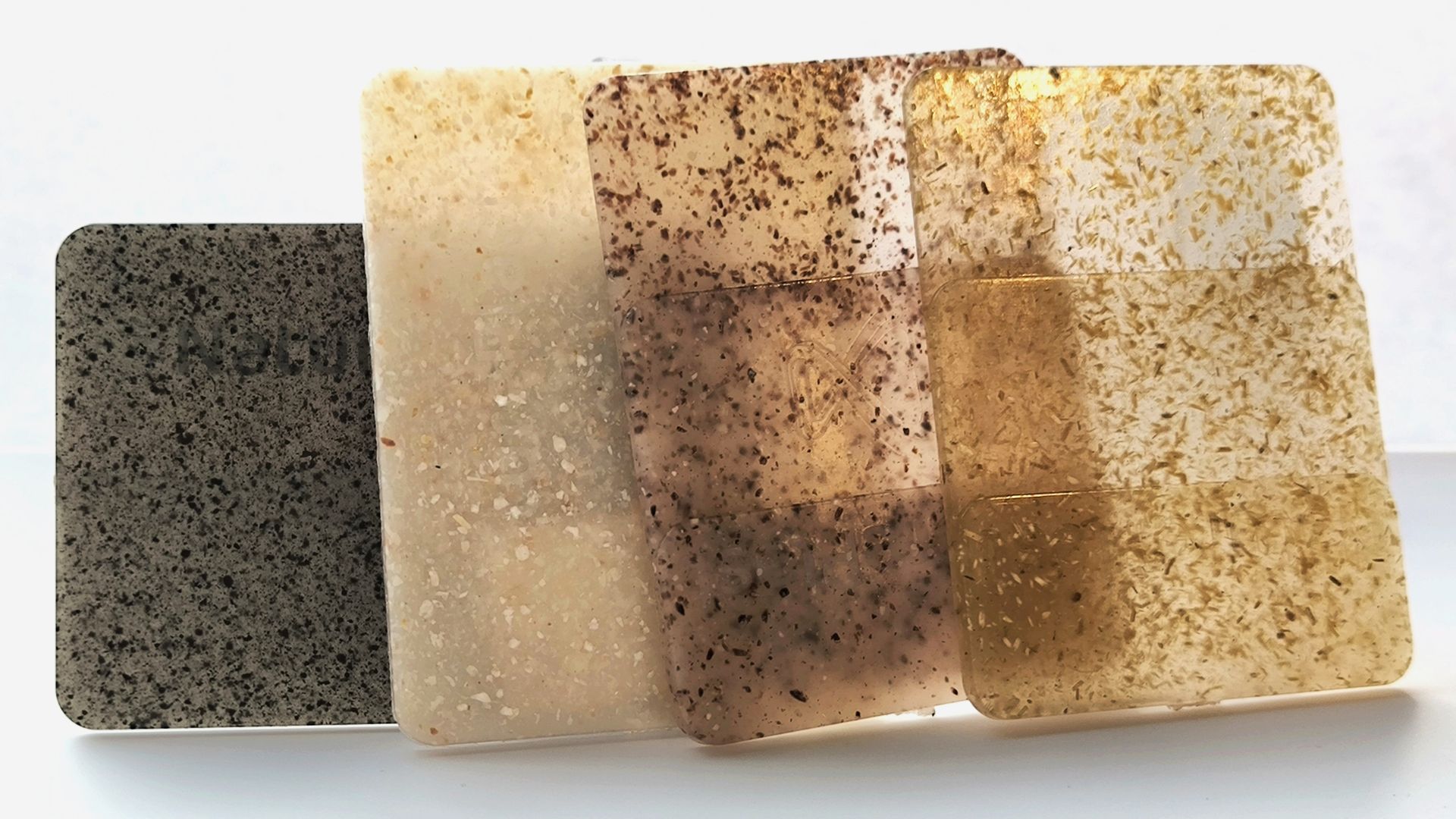

Among different options developed by Trifilon, the Revo series specifically integrates high-grade recycled polymers with plant fibers deriving from non-food competing sources such as hemp and wood cellulose. The polyolefin base compound comes from highly-consistent industrial waste streams generated in northern Europe. The reinforced compound then showcases overall great UV resistance, high impact properties – fundamental to the automotive industry – together with high fiber visibility.

The BioLite biocomposite series, whose composition is optimized for elongation and flexibility, is on the other hand suitable for packaging and casing products, allowing for an overall reduction of around 33%.of plastic needed to manufacture such items.

Applications and Customization

From automotive components to everyday consumer goods, as well as in the cosmetic sector, these materials represent a sustainable alternative that aligns with some aspects of the circular economy model. As it often happens in the sector of these specialty solutions, these biocomposites can be also tailor manufactured to meet specific sustainability goals and application requirements. This means that the percentage, dimension of reinforcing fibers can be decided upon orders as well as the final desired color.

Real world use cases in Design

One of the most compelling use cases of the Revo series is its application in the design of the Cake Kalk AP electric motorbike. This high-performance bike required a material that was lightweight, durable, and sustainable. A custom Revo grade was used in this design, which met these needs while contributing to the bike’s eco-profile with a 92% reduction in carbon emissions.

The same material, with a slightly different composition has been used by brand Very Good & Proper for their Latte armchair for outdoor applications. PhantomBio suitcase by Epic, at the same time, was one of the first, large-scale, suitcases created with a biocomposite material when launched in the market.

The growing and trending developments in the biocomposite industry are an example of how innovative thinking and commitment to sustainability can lead to the creation of new materials and aesthetics, such is the case of Trifilon. As the world grapples with the challenges of plastic waste and carbon emissions, these materials offer a glimmer of hope, demonstrating that it is possible to achieve environmental goals without sacrificing performance or design.