A new material toolkit to solve water scarcity

Focusing on accessible design, decentralised production, and scientific innovation, Water from Air points to new possibilities for clean water in the age of climate instability.

Global water shortage is currently one of the world’s most pressing issues, with over 2 billion people lacking access to clean water. Despite 70% of the Earth’s surface being covered in water, only less than 1% of it is drinkable, and it is estimated that 14 people die everyday from diseases related to inadequate sanitation. To tackle this, Louisa Grape and Julika Schwarz have created Water from Air, a mobile 3D-printed device that extracts potable water directly from atmospheric moisture, offering hope for communities facing water scarcity.

Gallery

Open full width

Open full width

Unlike complex industrial systems, Water from Air prioritises simplicity and accessibility, designed specifically for household use regardless of geographical or social circumstances. The device is capable of producing 6 litres of water per day through the use of Metal-Organic-Framework materials. These are revolutionary substances that can absorb water from the air like a sponge, and release it again as drinking water. While MOFs have typically been studied in scientific research contexts, this project brings their capabilities to real life scenarios.

Metal-Organic-Frameworks consist of metal ions or clusters, which act as nodes, and organic ligands, which act as connections between these nodes. They are characterised by an ultrahigh porosity and an enormous internal surface area, ranging from 30 to 6000 m²/g. They present a modular structure, which can be customised for different needs, mainly by modifying the spaces within the connected metals and linkers, called pores, so that they can accomodate particular molecules, like water in this case.

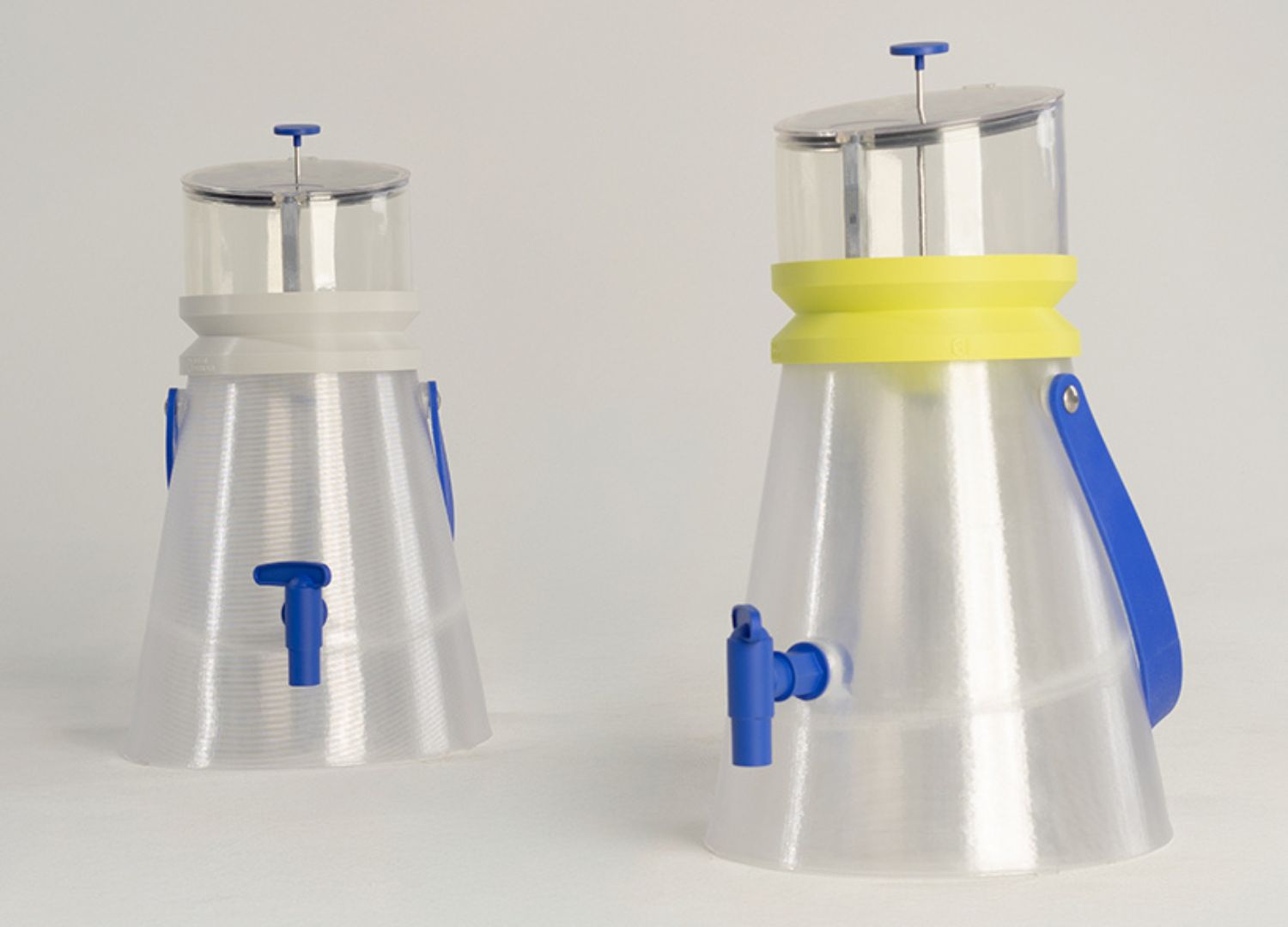

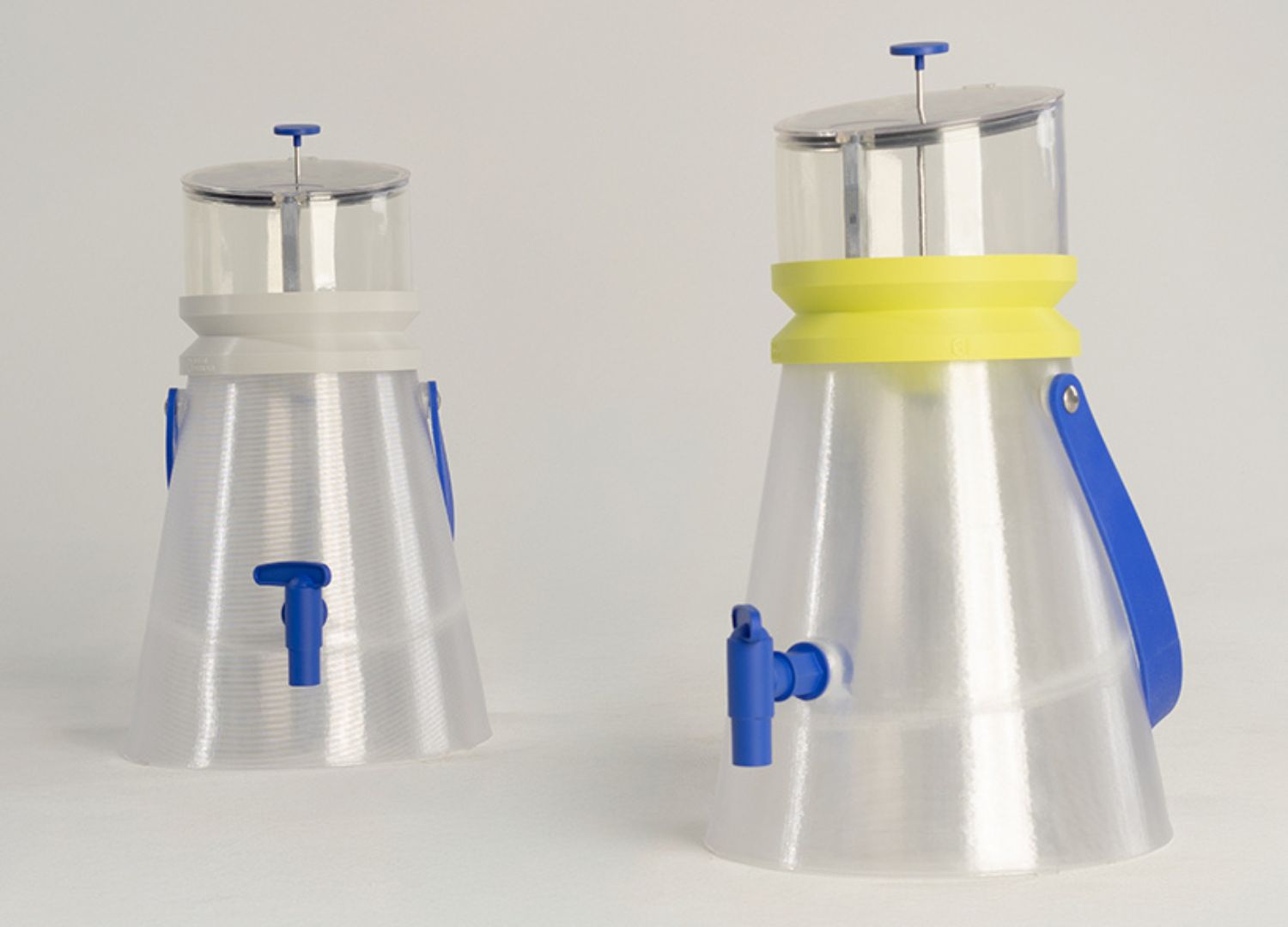

The device consists of multiple 3D-printed components, each optimised for specific functions. The water tank was printed with fused deposition technologies in transparent PETG, while the upper components utilise SLA printing for higher precision. Additive manufacturing plays a key role in making this technology accessible and scalable, enabling rapid prototyping, customisation, and the potential for distributed production.

The extraction process involves a two-hour cycle, where in the first hour the lid remains open, allowing MOF materials to absorb water from ambient air, and in the second hour the lid closes, and a natural distillation process occurs. This produces clean, drinkable water that can be easily accessed through an integrated tap system. The entire process requires no external energy and can be repeated thousands of times without degrading the material, making it ideal for areas with limited infrastructure.

As traditional water infrastructures often fail to reach remote or economically disadvantaged communities, decentralised solutions like this one are key for change. The device’s mobility and independence make it valuable for emergency situations, which are happening worldwide as natural disasters and droughts are rapidly becoming larger issues. Its scalable design also suggests potential for larger installations serving entire communities.

As climate change continues to exacerbate water scarcity globally, innovations like Water from Air offer tangible hope for sustainable solutions. By combining cutting-edge material engineering with accessible manufacturing techniques, this project shows how thoughtful design can address humanity’s most pressing challenges.