Mastering the look and feel of Lamitex CLPL® decorative surfaces

Lamitex creates avant-garde decorative laminates with exceptional aesthetic and technological properties. Now it’s launching an online configurator to make mastering the look that much easier.

Italian creator of avant-garde decorative laminates Lamitex has announced the launch of its online surface configurator, a new tool hosted exclusively on the company’s website, that offers customers access to a suite of editing and design tools to create 3D finishes. The tool allows customers to select any of Lamitex’ extensive library of finishes and decorations, optimizing aesthetics according to the user’s projects.

Without needing to download any software, users can explore Lamitex’s entire collection, discovering the materiality of its surfaces and downloading the textures to use in their own designs. From today, May the 21st 2021, Lamitex will launch a more immersive experience of its products using augmented reality, which can be accessed via a QR code and a mobile phone, enabling users the chance to view Lamitex laminates on any given surface or space, as users walk in and around it.

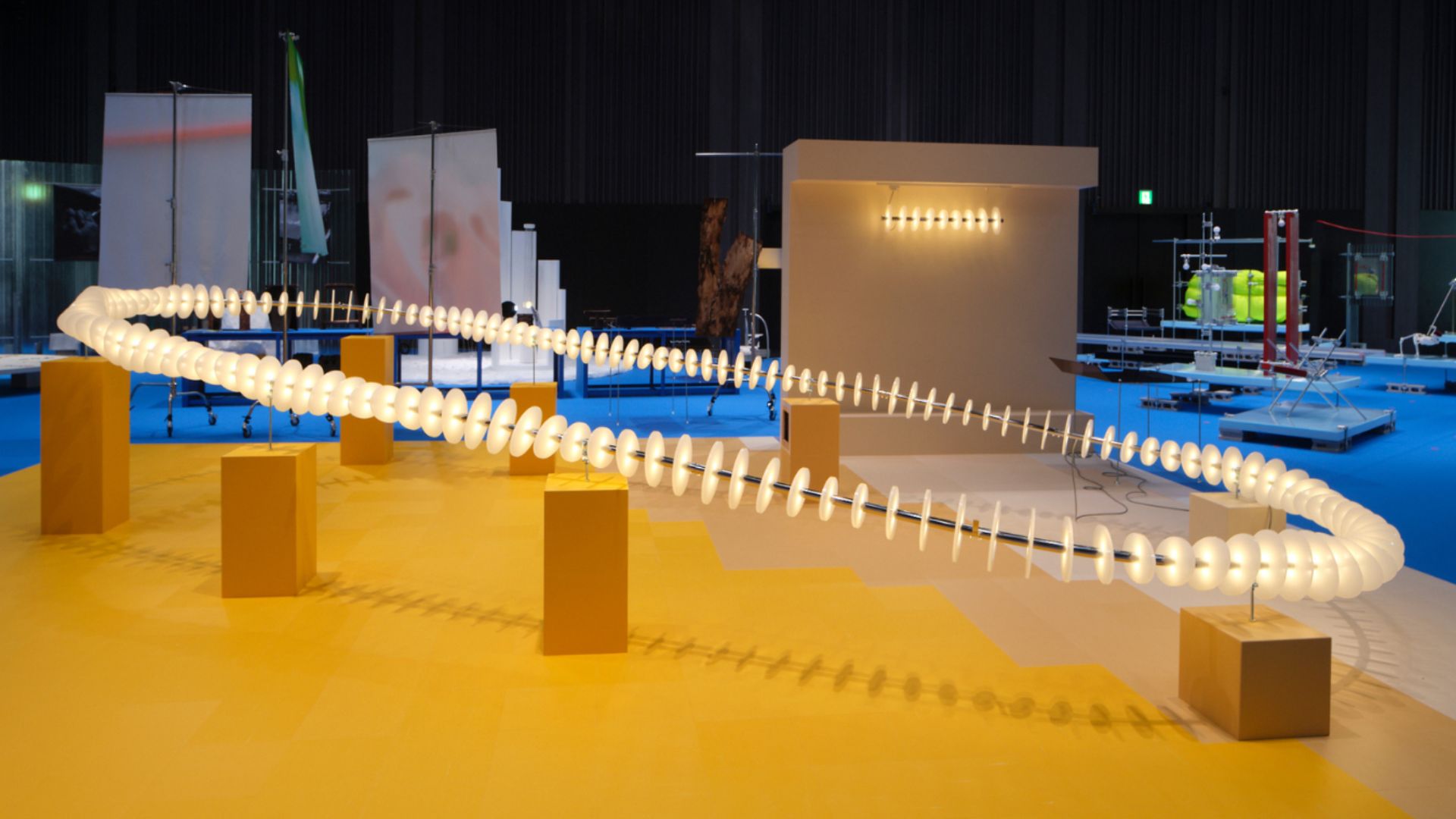

Gallery

Open full width

Open full width

The company has also recently launched a new website that intends to provide a digital space that guides users through the company’s key pillars and beyond: not only it enables to showcase its products with detailed information on 3D finishes and production, but this is also the place to discover the applications of Lamitex’ decor surfaces ranging from doors and furniture details to full-scale interior projects. Whilst communicating the uniqueness of the Lamitex product, the virtual experience celebrates technology, aesthetics and sustainability.

Celebrating 20 years of innovation

The announcement celebrates twenty years of Lamitex leading a revolution in decorative surfaces. Since 2001, the company has combined technological research and aesthetic creativity in the sector of interior design, furniture and furnishings. Lamitex was one of the protagonists of this evolution thanks to its CLPL® technology, the result of years of studies aimed at obtaining the perfect mix between maximum adherence to the profiles and the natural effect of the coating.

Made in Italy

From design and research to new product development and production, it all takes place entirely in Italy, in Spilimbergo, close to the city of Pordenone, ensuring that both the final quality of the work and respect for the ecosystem are guaranteed. With hundreds of varieties, colours, grain patterns and textures, there are surfaces to suit every taste, and with an effect almost identical to the real thing, Lamitex is able to reproduce the look and feel of wood, stone, cement and metal.

What are CLPLs ®?

To achieve a look that’s as good as the real thing, Lamitex uses exclusive technology to create what’s known as continuous low-pressure laminates (CLPL®). CLPL®’s boast an exceptional, hyper-realistic look thanks to a synchronized “open pore technology”, which is a hallmark of Lamitex and recreates the grain, contrasts and tactile sensations of different wood surfaces with total realism. In terms of performance, the laminates grant perfect adherence and flexibility, which makes them perfect for highly curved surfaces and soft 3D applications, ensuring maximum workability.

What’s more, the most common machinery for furniture production can be used to apply Lamitex on any given surface. Both industrial manufacturers and craftsmen can apply decorative surfaces to doors, frames, profiles or any other vertical surface for interiors. This exclusive process allows an optional CLPL® decorative embossing highlighting texture, depth and further emphasising their play on light, to achieve incredible realism.

This exclusive process allows optional CLPL® embossed decorations to be applied for warm effects of the wood grain and natural ash-effect wood textures, parallel and uneven lines enhancing tactile sensations, as well as sumptuously soft and wavy lines or coarse effect classical brushed embossings.

Great for interiors, better for the planet

As their name suggests, the CLPL® process employs low pressure, which means less energy is required. As a result, Lamitex’s decorative surfaces are better for the environment. They are also recyclable as they are made from 100% recyclable materials: sustainability is an important hallmark of the company, whose products have always been free from polluting agents such as phenols, melamine or added formaldehyde.

Furthermore, Lamitex uses cellulose as its main material to compose Lamitex products, a very flexible material, which doesn’t require special pressure or high temperature to be applied and formed into shape. Lamitex cellulose surface also helps to create its unique “soft 3D touch” resembling a realistic wood-touching experience.

After twenty years of innovation, Lamitex continues to master materials and achieve high-end, ultra-realistic surfaces made entirely in Italy and perfect for use across interior decoration.