Vestre is the world’s first furniture company to use a revolutionary fossil-free steel

Steel production is a vital aspect of our society, but it is also responsible for significant carbon dioxide emissions. SSAB, a Swedish steel company, aims to address this issue by employing hydrogen instead of coal and coke in the manufacturing process

For the Norwegian urban furniture producer Vestre, taking a leading role in sustainability initiatives is second nature. The decision of using SSAB‘s solution will make Vestre the first furniture company in the world to use this fossil-free steel in their production.

It is not a bold statement to say that carbon dioxide emissions must be drastically reduced worldwide if we are to have any chance of mitigating the effects of global warming and climate change.

Certain sectors and industries may have a more difficult and slower path forward, but everyone can and must contribute, fully in accordance with Vestre’s guiding principle and the motto ”Everyone can save the world. A little.”

Vestre aims to push the development and transition to more sustainable materials and production methods, to ultimately be able to offer a maximally sustainable product – something that more and more of today’s customers are demanding.

”Vestre’s furniture is built to last a lifetime and we only use the highest quality raw materials. Steel makes up around 69% of our total carbon footprint, making it one of our prime targets for decarbonization. We aim to be recognized as the world’s most sustainable furniture company, and to get there, we need to be ahead of the curve”, says Øyvind Bjørnstad, CSO (Sustainability Officer) at Vestre.

The Swedish steel company SSAB is already one of the world’s most carbon dioxide-efficient steel producers, but at the same time, they know that the industry as a whole still has a long way to go. Therefore, SSAB aims to make a real difference as soon as possible and lead the steel industry toward a carbon dioxide-free future.

The technology for fossil-free steelmaking that SSAB has developed is based on the HYBRIT initiative (Hydrogen Breakthrough Ironmaking Technology), which SSAB started in 2016 together with the mining company LKAB and the energy company Vattenfall. With the help of this technology, where coal and coke are replaced with fossil-free hydrogen, SSAB has the potential to reduce Sweden’s CO2 emissions by around 10 percent.

”It is fantastic to start this sustainability journey with Vestre since they share our goal of reducing the carbon footprint throughout the value chain. At the same time, the collaboration also shows the breadth of uses for our fossil-free steel”, says Thomas Hörnfeldt, head of sustainable business at SSAB.

Vestre has always strived to be at the forefront of the green shift and has always been quick to test new technologies and solutions to constantly reduce their climate impact: from having tied all business strategies directly to 9 of the UN’s 17 global sustainability goals in the Agenda 2030, to exclusively use high-quality materials, such as Swedish steel and Nordic woods from sustainable forestry, in their production.

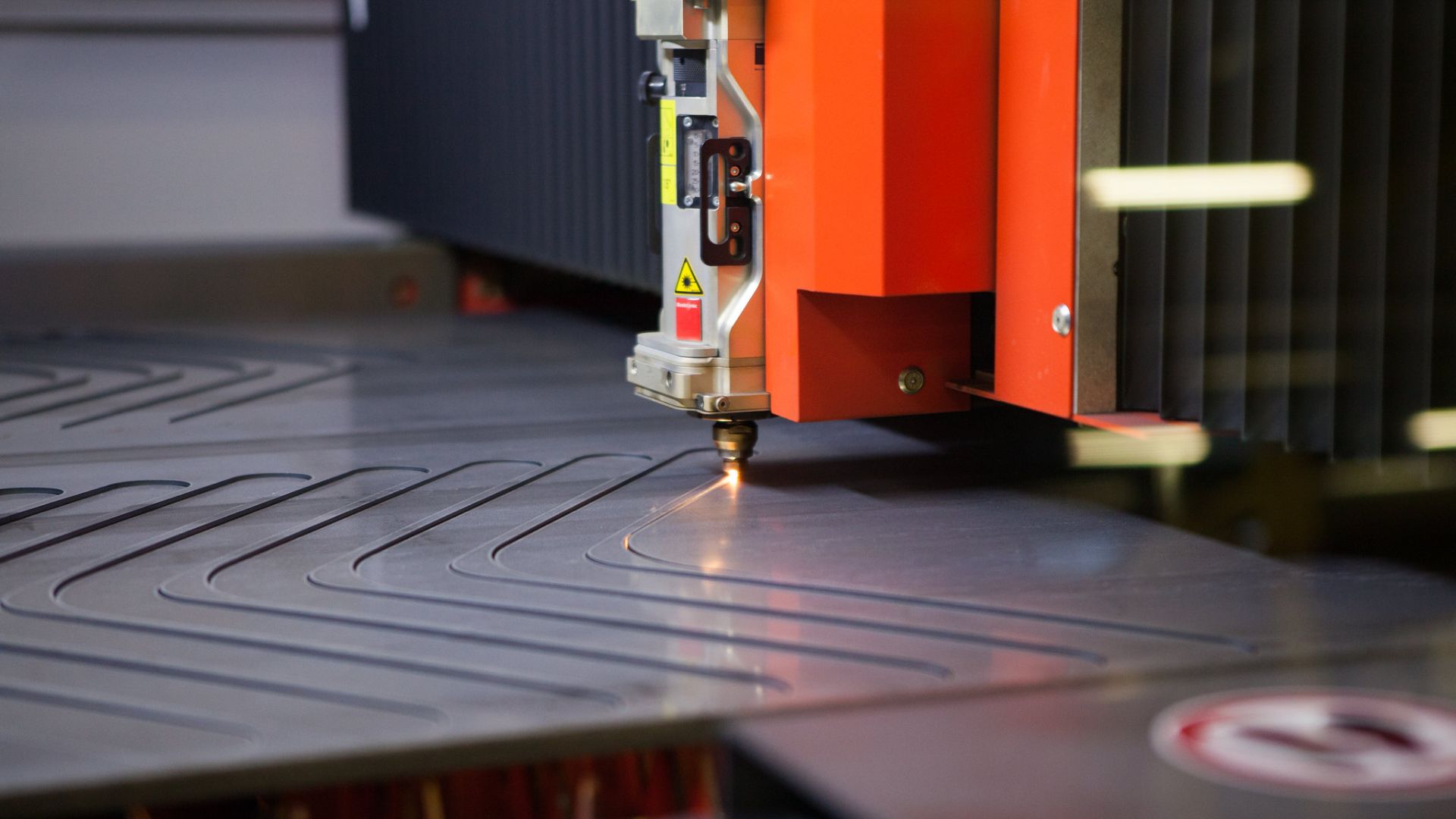

In 2022, Vestre also opened the doors to The Plus – the world’s most environmentally friendly furniture factory, located in Magnor in Norway, near the Swedish border.

”Fossil-free steel has great potential, and even if it will only be available in small quantities at first, it will have a big impact for us. SSAB is a pioneer in this area, and since we have had a long collaboration with them on our current steel – which has more than 20 percent lower emissions than the world average – it was only natural that we became a partner on the journey towards fossil-free steel“, Bjørnstad concludes.