Hydro’s recycled aluminium is revolutionising the metal materials industry

Made with a minimum of 75% recycled, post-consumer scrap, CIRCAL is an eco-friendly choice that slashes carbon emissions compared to conventional aluminium production.

In a world where sustainability reigns supreme, the quest for eco-friendly materials has become a top priority. Among these, aluminium stands out for its versatility and recyclability, offering a promising solution to modern challenges. But what sets aluminium apart, and how is technology reshaping its landscape? Get to know more about Hydro CIRCAL.

Hydro is a Norwegian powerhouse at the forefront of aluminium innovation. With a legacy spanning over a century, it has evolved from tackling historical challenges to pioneering a greener future. Headquartered in Oslo, the company boasts a global presence, with 33,000 employees across 140 locations in 40 countries, including numerous plants across Europe.

Gallery

Open full width

Open full width

Guided by the principles of slow design, this company is revolutionising the industry from production to end-product. Since its founding in 1905, the company has been dedicated to solving pressing challenges of the time. Today, Hydro is changing the game by providing greener materials crucial for sustaining the world’s rapid development.

Pioneering sustainability in aluminium production

Since 1990, Hydro has made significant strides in reducing emissions from its Norwegian smelters by over 50%, all while increasing production by 40%. Looking ahead, the company aims to further reduce its total carbon emissions by 30% compared to a 2018 baseline by 2030. Moreover, they are committed to delivering industrial-scale pilot volumes based on emission-free smelting technology.

At the core of Hydro’s work lies a revolutionary approach to aluminium. By turning natural resources into a material vital for modern society, the company emphasises transparency, decarbonization of production, social justice, and contributing to nature positivity. As the company progresses towards a greener future, it aims to bring industries reliant on aluminium, such as automotive and construction, along for the journey.

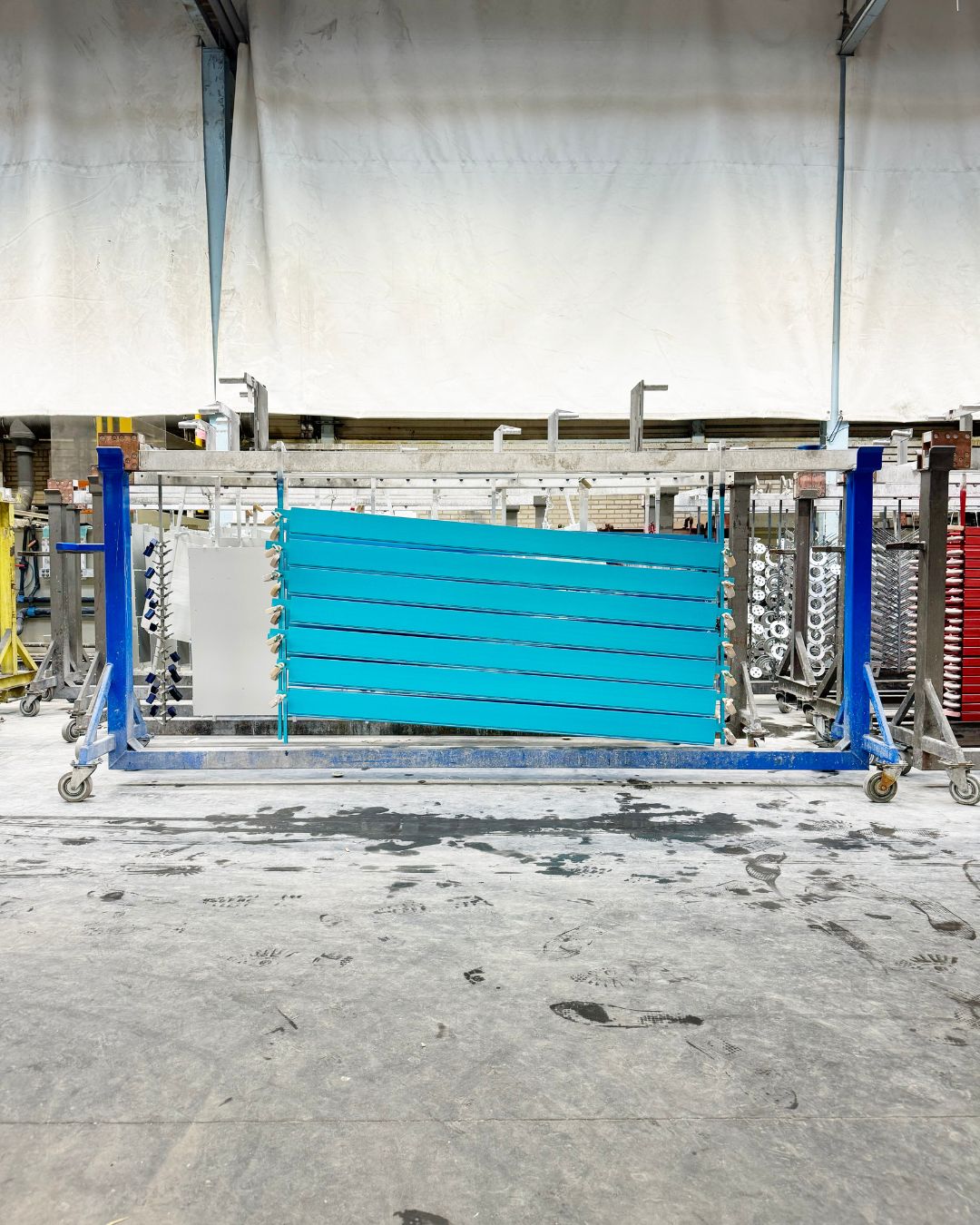

One of their flagship initiatives is Hydro CIRCAL, a range of premium recycled aluminium products. Hydro CIRCAL utilises advanced sorting technology to remelt scrap into electric vehicles, designer furniture, consumer electronics, and building facades. With a commitment to transparency, the production and raw materials in Hydro CIRCAL can be traced on an individual batch level.

Sustainable solutions for a circular future

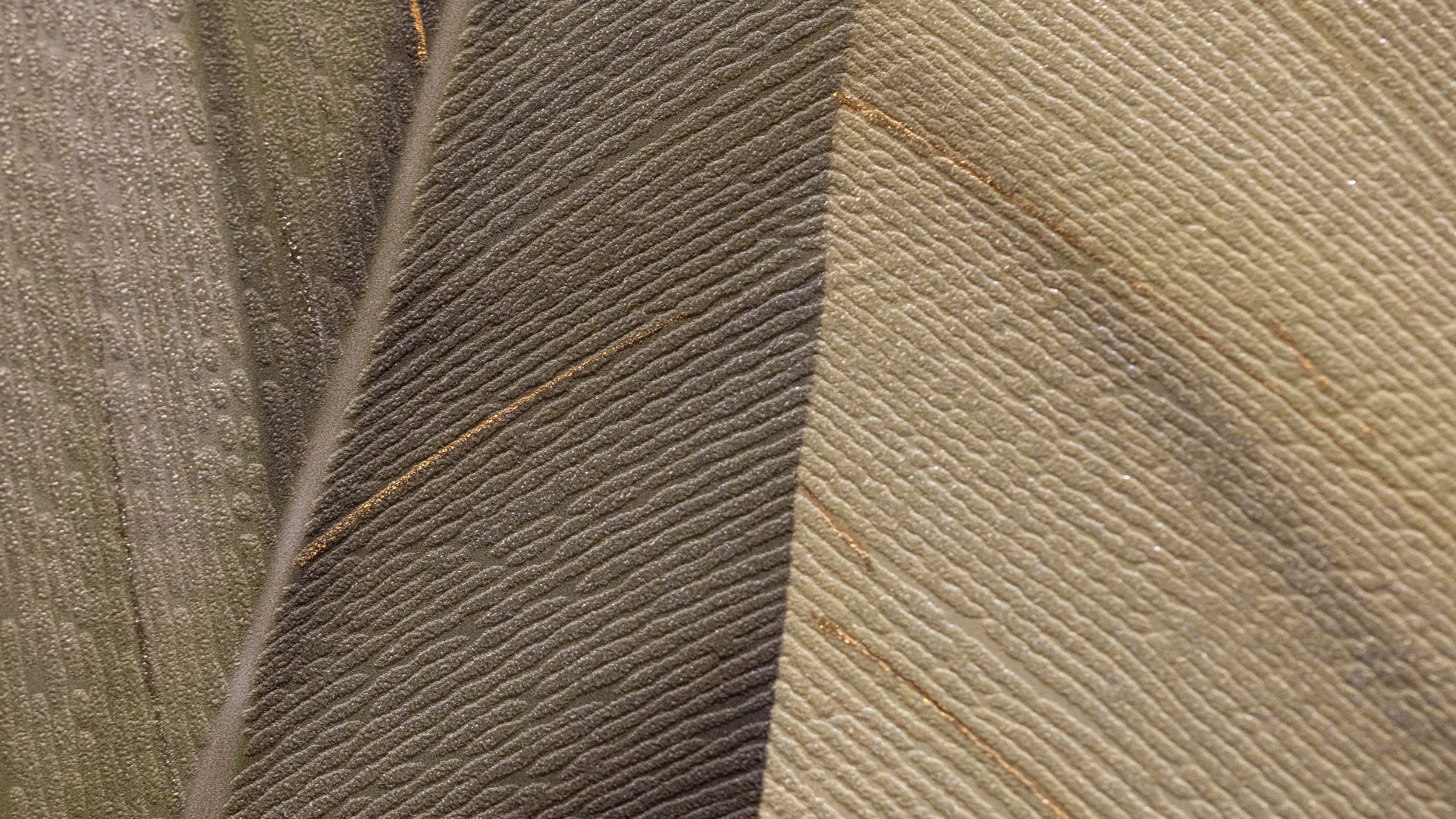

Aluminium, being a circular material, can be infinitely recycled without any loss of quality. Approximately 75% of all aluminium ever produced is still in use today, showcasing its sustainability credentials. Recycling aluminium requires just 5% of the energy needed to produce primary aluminium, making it a highly efficient process.

“Whether it’s old windows, wheels, or beverage cans, recycling aluminium requires just 5% of the energy needed to produce primary aluminium,” explains the company. “Recycling scrap requires the removal of unwanted elements like paint, lacquer coating, oil, plastics, iron, minerals, and organic compounds. It is a technical and complicated process dependent on factors like scrap origin, original chemistry, previous use, and physical properties.”

Decades of research and development have positioned Hydro as a pioneer in aluminium recycling. The company is based in Norway with a global network of smelters and recyclers, and owned bauxite and alumina production in Brazil. It operates in a broad range of market segments for aluminium, energy, metal recycling, renewables, and batteries, offering a unique wealth of knowledge and competence.

“From an origin as a fertiliser producer to feed a starving population, to oil and gas extraction to propel an evolving society, we have been in business since 1905. Today our 33.000 employees are committed to solving the pressing challenge of climate change with low-carbon, recycled aluminium that enables the green transition,” it explains. With a global network of recyclers operating patented technology, Hydro aims to double its current recycling capacity for end-of-life scrap by 2030.

Its flagship initiative Hydro CIRCAL is categorised by the percentage of scrap content, includes Hydro CIRCAL 100R and Hydro CIRCAL 75R. Hydro CIRCAL 100R is made from 100% recycled post-consumer scrap, boasting a carbon footprint below 0.5kg CO2e per kilo aluminium – 97% lower than the global average for primary aluminium.

Driving Change: Hydro’s Sustainable Aluminium Solutions

“We have a strong foundation to build on, with expertise and competence built up over 118 years of developing sustainable businesses,” explains the company. “We are thousands of engaged colleagues throughout the world, in energy and aluminium. In many areas, we stand out as number one in our industry with leading technology and know-how.”

“These are natural next steps, building on the foundation of the 2025 strategy, and leveraging our entire value chain to support one common strategic ambition: To pioneer the green aluminium transition, powered by renewable energy.”

Their commitment to sustainability extends to its aluminium design services, which help clients reach their sustainability goals while meeting the demands of climate-conscious consumers. Looking to the future, Hydro plans to step up growth in aluminium recycling and extrusions, alongside renewable power generation. With a strategic focus on pioneering the green aluminium transition, powered by renewable energy, Hydro is poised to shape the industry for generations to come.