From e-waste to innovation: Open Funk’s mission to transform home appliances

Design is often seen as the intersection of creativity and purpose, and few embody this fusion as seamlessly as Open Funk.

Born from the partnership of two designers with vastly different origins but a shared vision, Open Funk stands as a testament to the power of collaboration and innovation. Ken Rostand, with roots spanning the lush landscapes of French Guiana and the vibrant streets of Marseille, brings a lifetime of visual curiosity and ecological consciousness to the table. Meanwhile, Paul Anca, hailing from post-communist Romania, carries the ingenuity and resourcefulness of a maker culture that thrived on necessity and adaptability.

Together, they have crafted a design philosophy that marries aesthetics, functionality, and sustainability—pushing boundaries and reimagining what household appliances can be in a circular economy. This interview delves into their unique journeys, design principles, and the bold vision behind their innovative project, re:Mix.

How did your design journey begin?

Open Funk:

“We’re two designers, coming from different worlds.

Ken Rostand:

“I grew up in between French Guiana (South America) and Marseille (France), and I have been drawing stuff since I can remember. My early years spent by the Amazon rainforest, the Mediterranean Sea and the old industrial and cosmopolitan town of Marseille have surely influenced my human and ecological values, visual curiosity and design journey. Throughout my teenage years, I got fascinated and obsessed with aesthetics, visual arts, useful inventions and industrial design. I ended up studying mechanical and production engineering, design engineering and industrial design, to learn how to create and build sustainable lifestyle products in the manufacturing world.”

Paul Anca:

“I grew up in post-communist Romania. While the design culture was getting a fresh start, everyone seemed to have a strong maker attitude: what you own, you fix. My first introduction to design came when I was finishing my studies in economics: I was building a dating app with some friends, and somebody needed to design the UX. So I took a go at it and ended up as a self-thought UX designer. The power of creating something with intention and seeing it realised planted a seed in me that I still carry around with me every day.”

How would you describe the design philosophy and approach of Open Funk?

Open Funk:

“In a nutshell, it’s a design philosophy and approach good for people and the planet. More concretely, it’s about carefully balancing out circularity of parts and materials, aesthetics and ease of use.

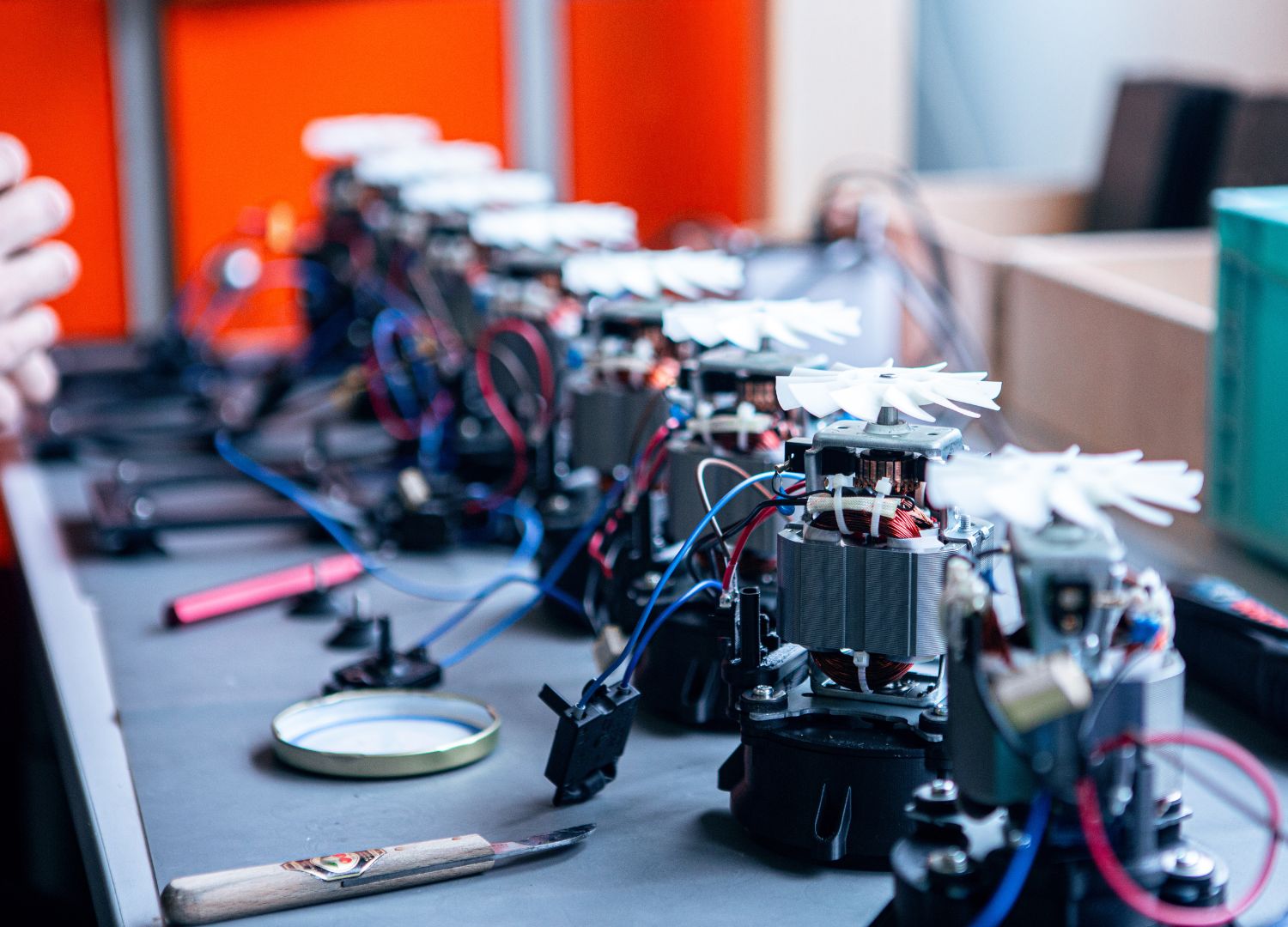

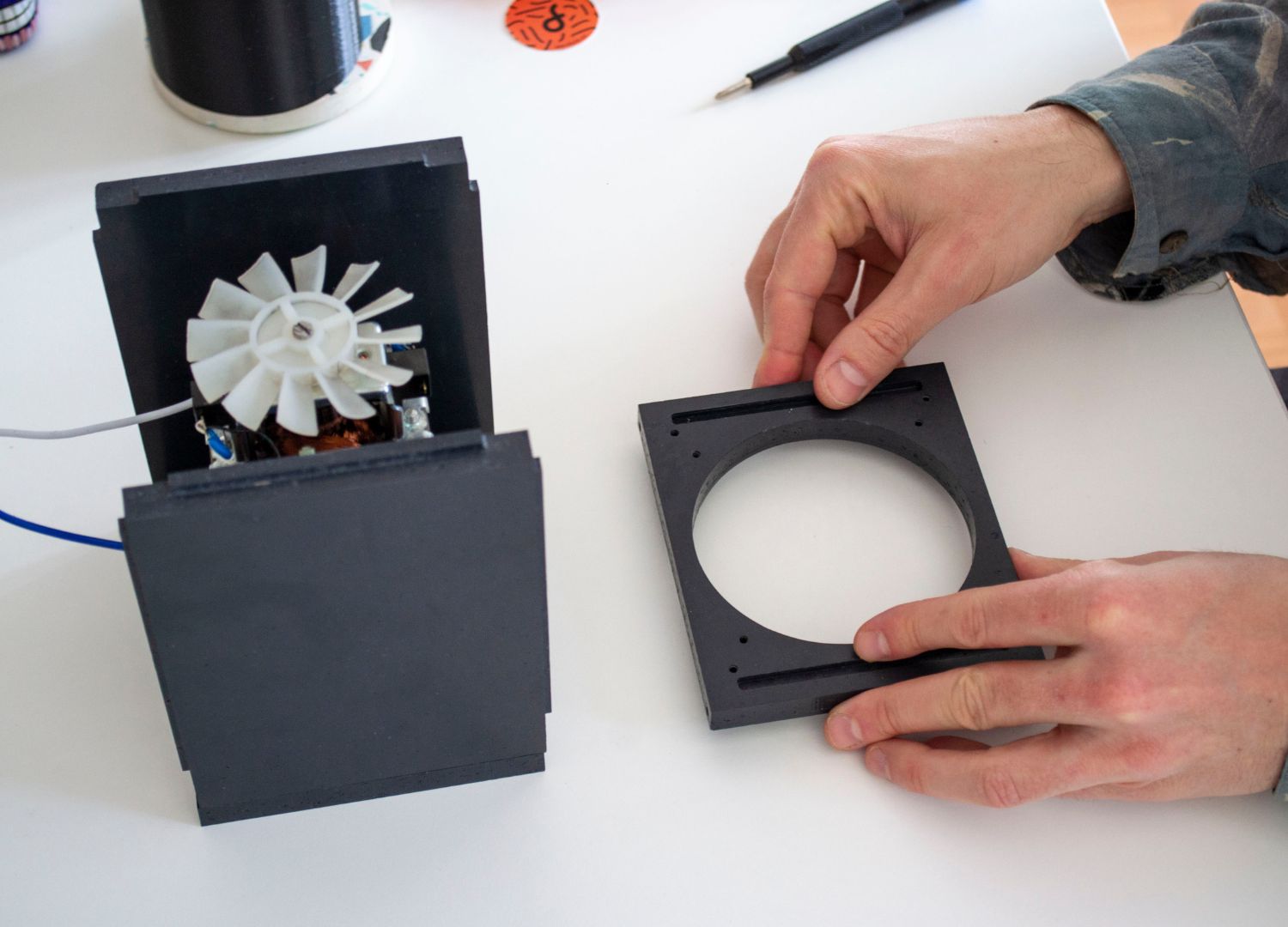

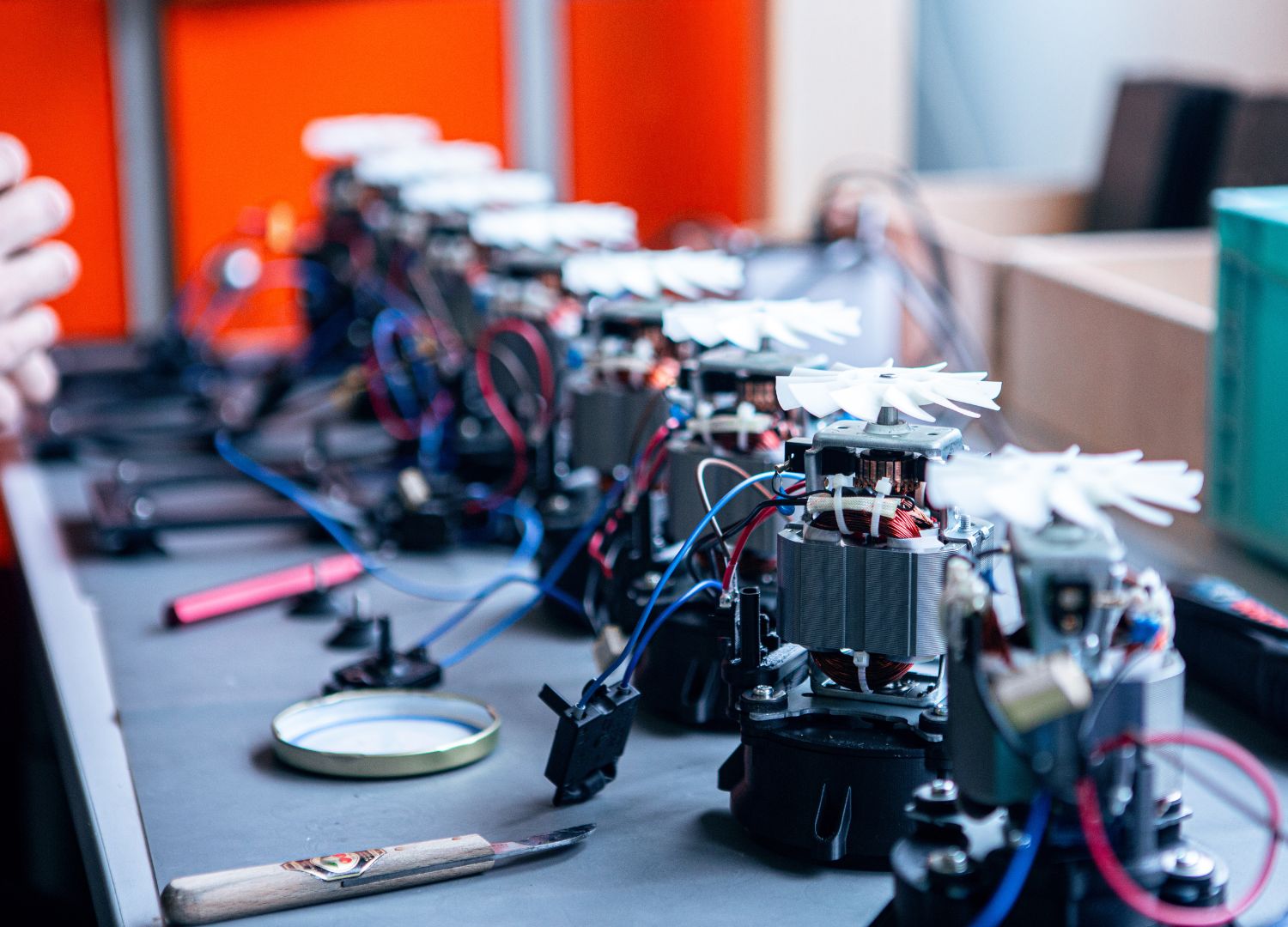

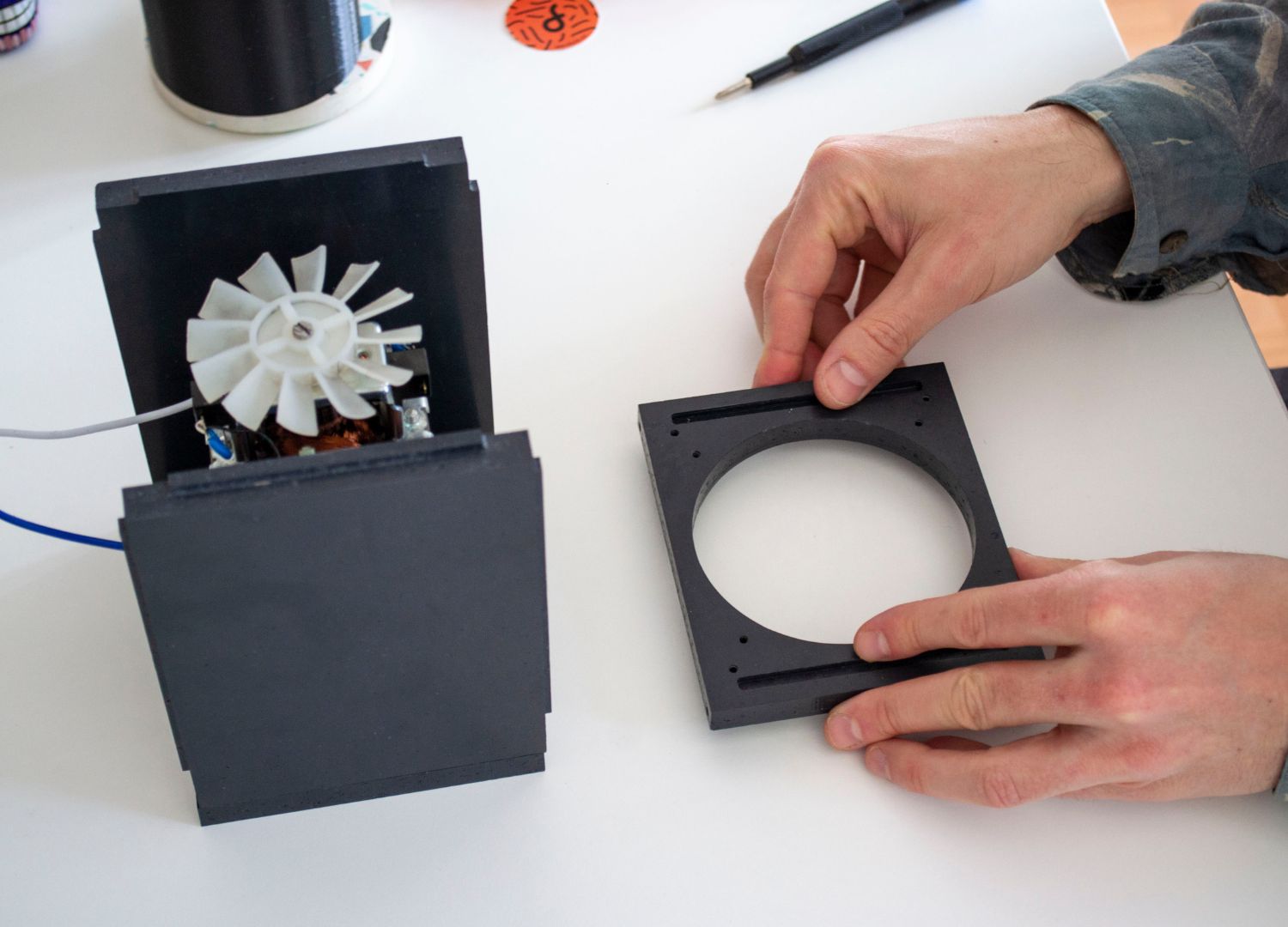

For circularity, we took great inspiration in the work and circular design principles of the Ellen MacArthur foundation. Modularity, durability, upgradability and repairability are built-in circular design principles we have adopted. Beyond design, we’re crafting re:Mix in our atelier in Berlin, using decentralised manufacturing technologies such as 3D printing and CNC milling, sourcing all our materials and most of our parts regionally. We’re sharing our design files and technical documentation open-source with users and maker-spaces to educate, enable repairs and collaborate on remanufacturing.

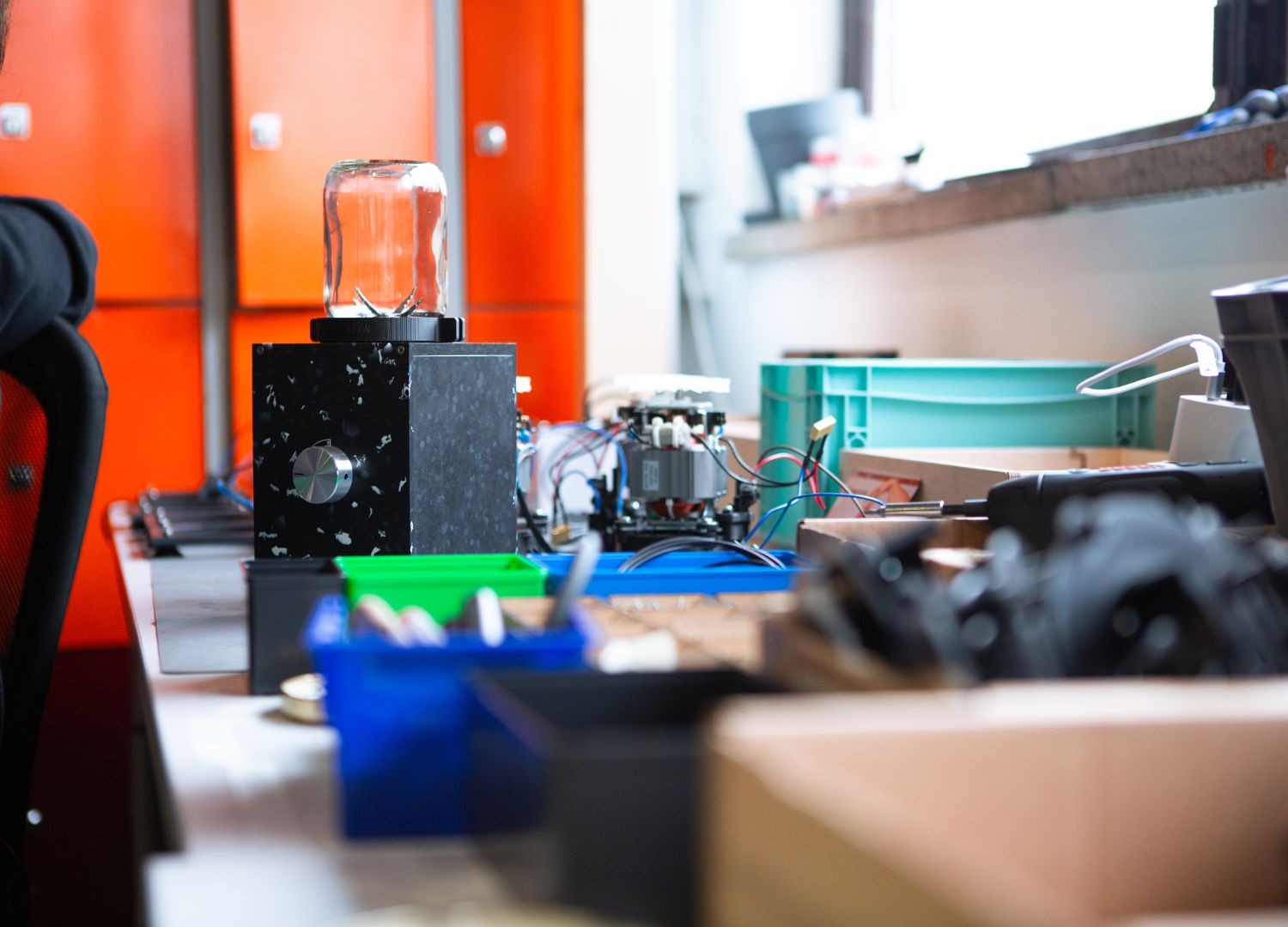

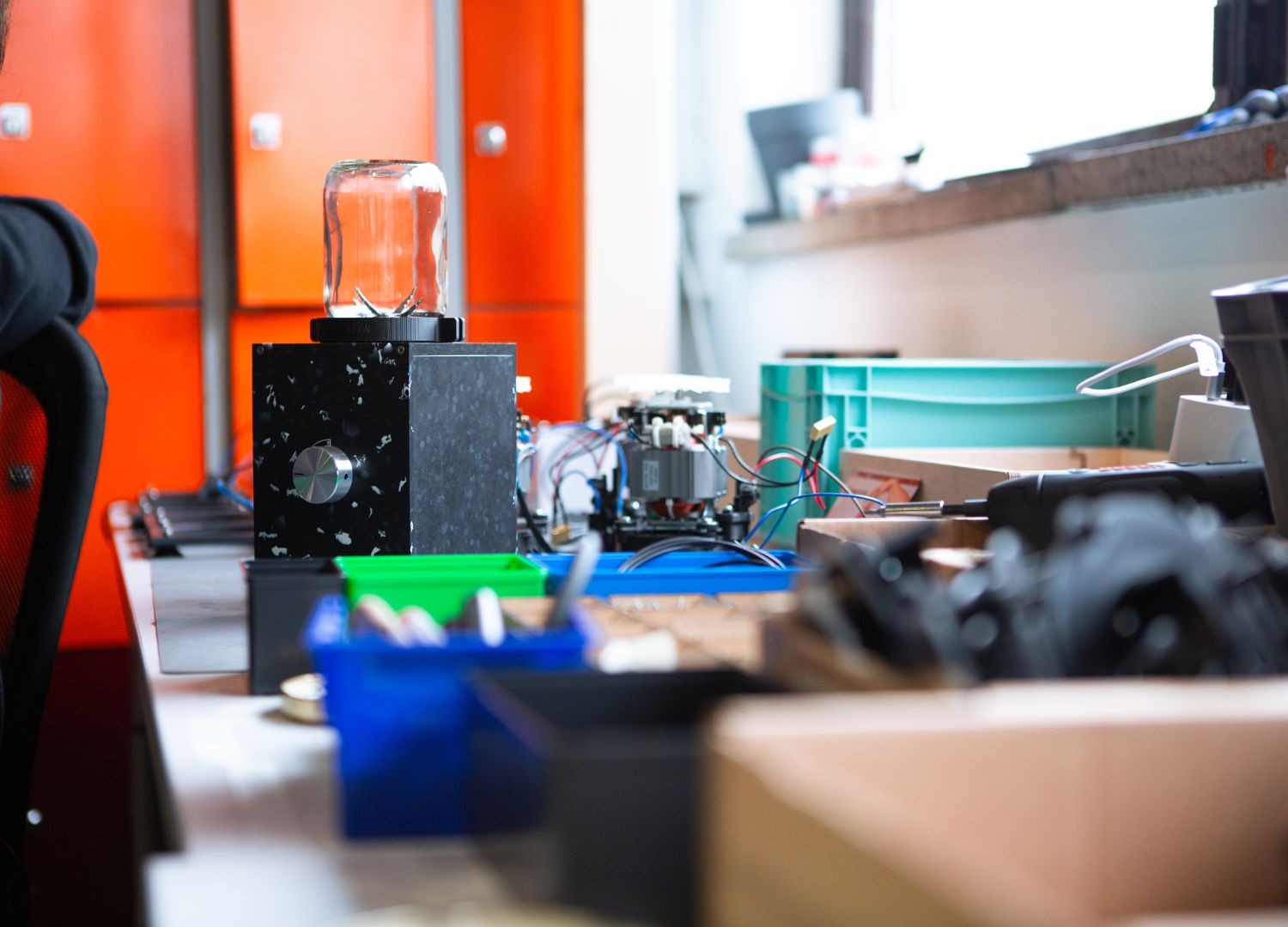

True circularity shouldn’t compromise but redefine aesthetics. By using beautiful recycled-plastic panels and openly-visible screws, we aimed for a look that’s both minimal Bauhaus and terrazzo Art Deco, showcasing recycling, modularity and repairability.

Lastly, through ease-of-use, the product should be practical and enjoyable to use. By adapting to universal glass jars, the user has huge flexibility in choosing the recipient size and purpose (drink up now, take as to-go, store for later), and significantly reduces the cleaning burden after blending compared to other blenders. It also reduces food waste by blending the food directly in its storage container, avoiding food to be wasted from one container to another.”

What inspired the creation of the re:Mix project? What led you to focus on this specific type of product?

Open Funk:

“From electronic waste and huge CO2 emissions to poor working conditions and long supply chains, kitchen appliances contribute to some of the world’s most serious environmental and human rights problems of our times. They break easily, inhibit repairs and offer spare parts at exorbitant costs. It is in this context that e-waste has become the fastest-growing waste stream worldwide, with 62 million tonnes per year.

After meeting at the aptly-named Open Source Circular Economy Days Berlin and becoming close friends, we noticed we could put our complementary skills to use and challenge this wasteful, linear way of making home electronics.

The kitchen blender checked a lot of different boxes: we both had kitchen mixers that broke within months from purchase, so we knew there was a problem; it is a useful product, as proven by the fact that most households have one; it is moderately difficult from a technological point of view – not as simple as a lamp, and not as complex as a phone, technological obsolescence is not an issue, people are willing to pay a good amount of money for a good blender, and lastly it contributes to a healthy and sustainable lifestyle.”

You have made circular economy a guiding principle. In your opinion, which product categories (still within the realm of appliances) could follow your example, and why?

Open Funk:

“Circular economy principles are easier to apply to products that do not go obsolete with technology. For example, a blender 30 years ago wasn’t that different from one today. The same applies to a toaster and most of the home appliances. Sure, the industry will try to convince you that an app with AI to control your blender is a must-have feature, but this is nothing more than a fad.

Let’s design one-off devices that last basically forever, that are repairable, and organise our logistics accordingly. Of course, if your business model dictates you to sell millions of devices just for the sake of growing forever, you’ve chosen the wrong goal. These are product and business design decisions that are in our power to take.

If you add those circular design principles as design requirements for your product and business, then it becomes a matter of creativity, R&D budget and strong will to challenge and redesign the existing technical, supply chain and business model benchmarks in place in the industry. We hope our example will inspire a whole generation of designers and business leaders to follow that circular path.”

What are the biggest challenges in creating a project that follows circular principles? What insights have you gained that could benefit other designers?

Open Funk:

“The challenges will depend on the type of organisation you have. For example, as a startup, we had the freedom to dedicate R&D on developing our own modular design, adapting to existing glass jars, developing easily replaceable 3D printed parts and refurbishable recycled plastic panels, and publishing our files open-source. If you’re in a multinational, the cost pressure and property rights might make these decisions impossible, so your leverage points will be different.

One big design challenge we had was making re:Mix compatible with universal, reused glass jars. It took us many months of R&D and iterations to develop a blade head that can adapt to these jars, and that is also safe, durable and easy to use. The fact that we’re using 3D printing as a manufacturing technology for our series production makes for a great advantage, allowing us to iterate and improve the design of each part from one day to another.

Another big challenge we had doesn’t have to do with circular principles at all: it’s financing. As a small startup, we’ve struggled with managing our cashflow, as we relied largely on pre-orders to make the project happen. We were able to pull in some additional funds via grants, but we’d love to see more public funding opportunities for circular business start-ups like ours. It’s worth remembering that even though you’re focusing on sustainability, market rules apply to you as well.

Lastly, by setting up our own manufacturing hub in the heart of Berlin, it has been a real pleasure to connect with people through something as technical as a kitchen blender. Having curious people and potential customers to visit our manufacturing hub, ask critical questions and open up our blender simply makes this entire project more human. This element is totally lost when we outsource production to faraway places, or start treating assembly workers and products sold as mere numbers on a spreadsheet. Local production comes with many environmental and societal benefits.”

How do you measure and assess the impact of your projects compared to traditional alternatives?

Open Funk:

“We have 7 metrics we use for our operations, some of which were pioneered by Fairphone. We’re still just getting started and refining them as we move along:

- Create a market for ethical, sustainable household appliances. (# of products sold)

- Creating products that last (# of years of product life until we take back / buy back the product)

- Circulating regional materials (Average % of parts and materials sourced regionally and sustainably)

- E-Waste neutrality (# of products and parts recovered vs products sold)

- Climate neutrality (# of company-wide emissions)

- Putting people first (Good working conditions as # of people)

- Promoting a broader impact within the industry (Assess industry impact as # of system points)”

Anything else you would like to add?

Open Funk:

“We currently have an open investment round to boost our growth. If you’re an impact-first investor or fund, please reach out to us and let’s talk about the future of sustainable home appliances.”