How to make 3D printing more accessible: the story of Prusa

From a startup to a global player in this industry, Prusa has created a true ecosystem of innovative hardware and software that aims to make the sector more intuitive and open-source.

The story of Prusa Research begins in 2012, the year Josef Prusa, a Czech hobbyist, maker, and inventor passionate about 3D printing, founded his startup based on the principles of the open-source RepRap project. The project’s goal was to create easy-to-use and affordable printers.

The company, headquartered in Prague, has experienced considerable growth and today, 13 years after its foundation, employs over 1,000 people with a shipping volume reaching 10,000 printers per month across more than 165 countries.

Prusa’s success started with its first product launched on the market, the Prusa i3 (MK0 model): intuitive, easy to build and modify, low-cost, and open-source licensed, it immediately became popular in education, among hobbyists, and professionals.

Gallery

Open full width

Open full width

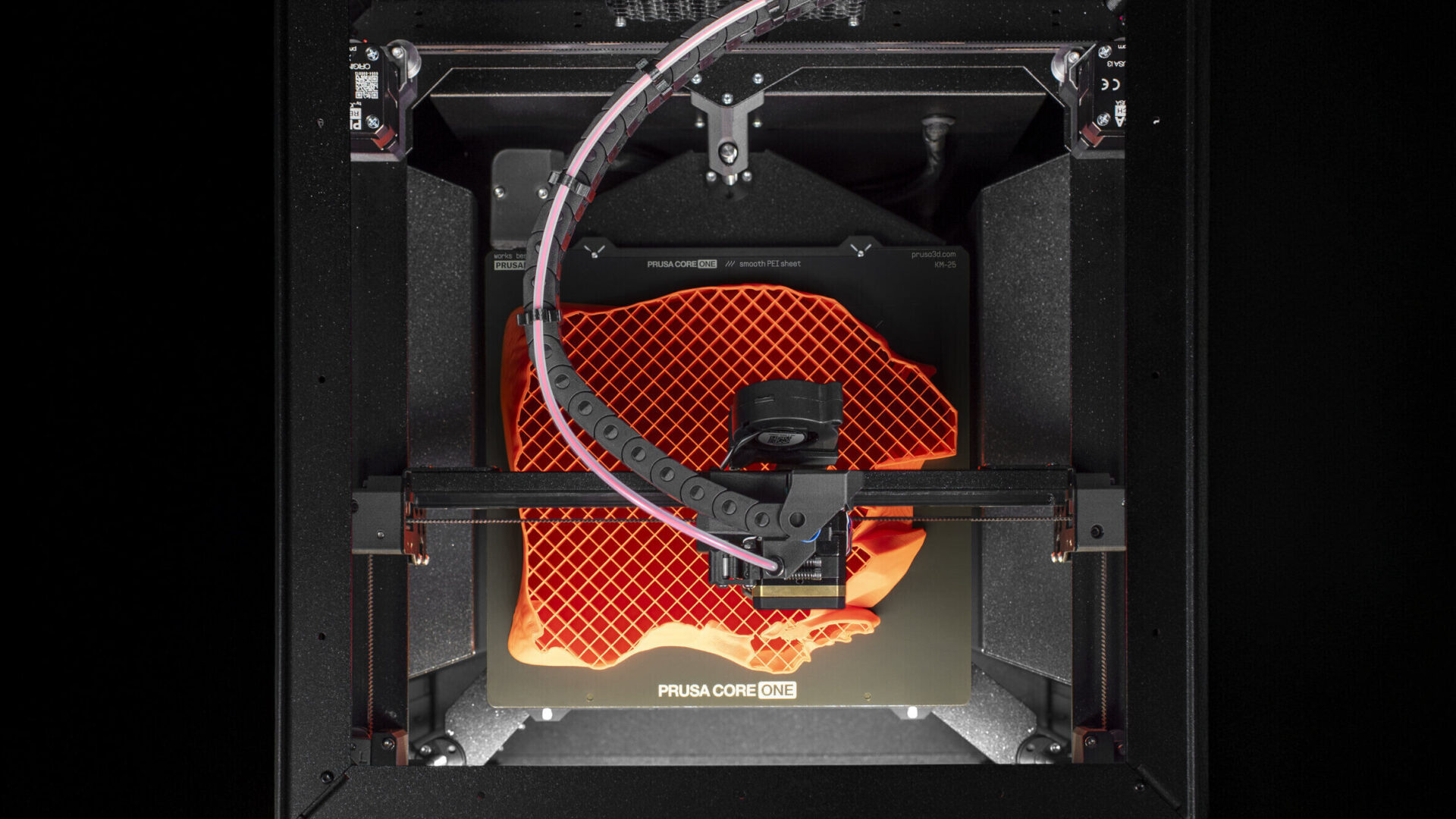

Over the years, the series has expanded, also receiving international recognition, and other models have been introduced to meet market demands, such as the Original Prusa SL1 (SLA printer), the Original Prusa Mini (with a cantilever arm), the Original Prusa XL (which uses the CoreXY method – a printer that uses a complex belt system powered by two fixed motors on the frame to move the print head along the X and Y axes), and the Prusa CORE One, also based on the CoreXY method. The latter was awarded this year with the Red Dot Design Award in the category Industrial Equipment, Machinery, and Automation.

To ensure the reliable use of its tools and better control over print quality throughout the entire process, the company introduced an important innovation in 2018: the in-house production of its own filaments at the Prusa Research facility through a new subsidiary, Prusa Polymers. This gave birth to Prusament, the brand under which these filaments and resins are marketed. A dedicated R&D team constantly develops new colors and materials, including high-quality recycled filaments.

The Prusament production has expanded to over 20 lines in a dedicated warehouse by 2025. Every spool is perfectly wound and produced under strict in-house standards: while most filament manufacturers guarantee a diameter tolerance of ±0.05 mm, Prusa sets the limit at ±0.02 mm (±0.03 mm for blended materials). The diameter is measured along both axes multiple times per second to ensure maximum precision and excellent roundness. This higher level of consistency means fewer failed or low-quality prints.

User focus also makes the difference: each spool comes with a unique QR code and product ID, allowing customers to check detailed production data online at Prusament.com. Sustainability is another key aspect — Prusa designed its spool to use 50% less plastic than standard ones and continues to expand recycled material lines and product passport initiatives.

In parallel, Prusa has developed a true ecosystem for makers, going beyond hardware to also embrace software, components, and 3D models, always in an open-source spirit: starting from printer firmware to its own slicing software. Prusa initially used Slic3r, a 2011 project by Alessandro Ranellucci. In 2016, an internally developed version called Slic3r Prusa Edition (Slic3r PE) was released to optimize the software for Prusa machines and enable faster feature additions and simplified development. In 2019, this effort evolved into PrusaSlicer, an original and independent codebase. Today, it is one of the most widely used slicing software in the desktop/prosumer segment.

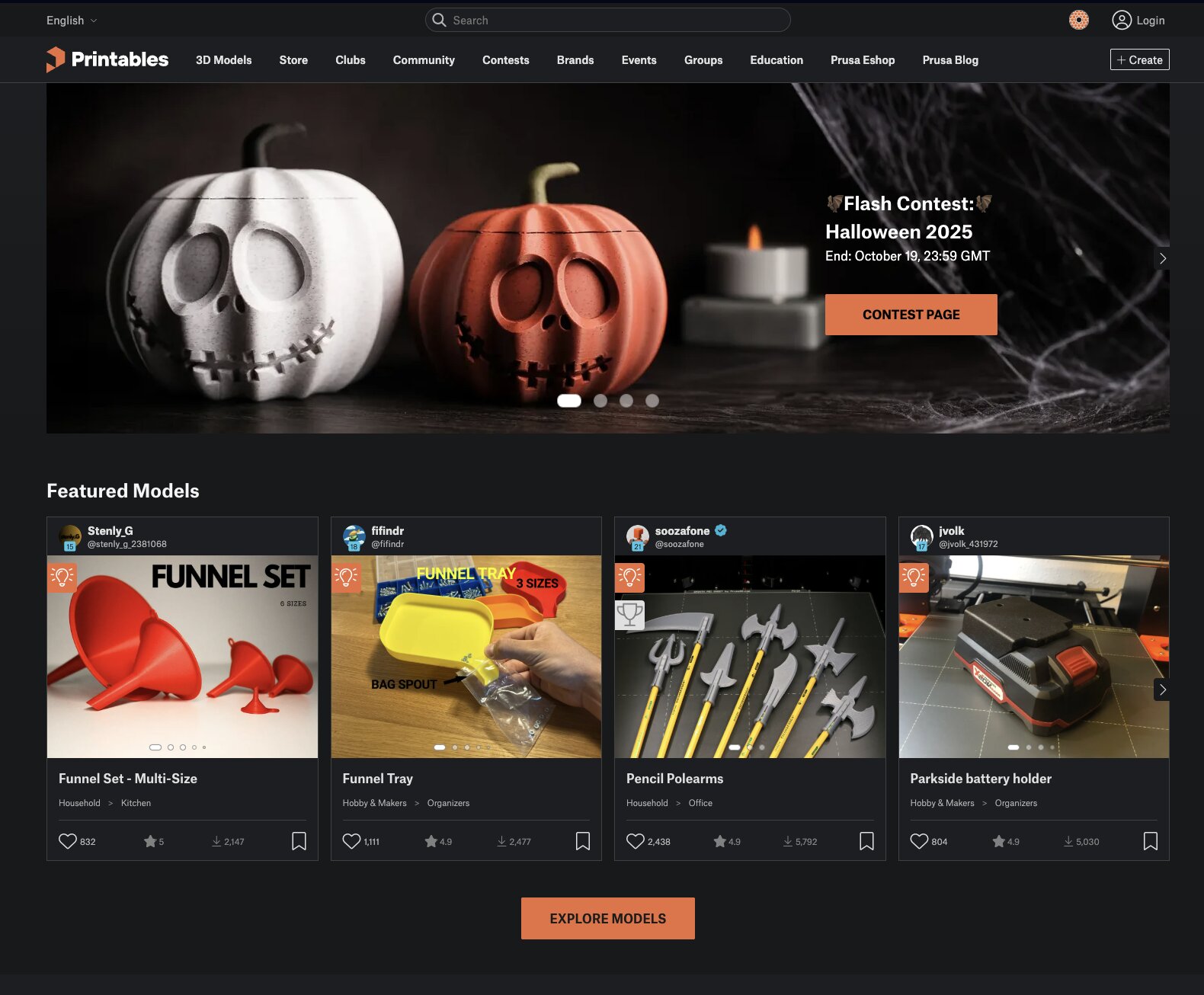

Prusa’s innovation is not only dedicated to individual users but also to the entire community, as demonstrated by the PrusaPrinters.org Community Hub, launched in 2019 and rebranded in 2022 as Printables.com to open up to all 3D printer owners.

Today, the site is a true social platform for the maker and open-source movement, free and global: users can find an online library with hundreds of projects – from decorative objects to technical components – uploaded as files in different formats (STL/3MF/G-code), both free and paid, complete with instructions, preview images, and the license chosen by the creator.

Users can create personal profiles, follow other designers, leave likes and comments, participate in contests, and build thematic collections of models. For the more active part of the community, it is also possible to monetize their projects through the integrated store or the Printables Club, designed to directly support creators. A new Community Articles section allows users to publish their own text with project descriptions, walk-throughs and helpful tips.

Prusa’s most recent innovation, which brings together all the themes and values of the brand, is Prusa EasyPrint, the feature designed to make 3D printing even easier and more accessible. Created to help beginners, Chromebook users, and tablet power users, it is an optional, free service integrated into the Prusa App as well as via a browser on Printables.com. Unlike PrusaSlicer, EasyPrint simplifies the process even further: just select a model, choose print quality or material, and press “PRINT.” The tool allows the user to use only the essential options – move, scale, rotate, or add supports – to guarantee simplicity and accessibility.

In just under 15 years, Prusa Research has become a benchmark in the world of 3D printing. From manufacturing printers and filaments to creating an online platform and new digital tools, the company continues its innovation journey without forgetting its starting point: making this technology simple, accessible, and open-source.