How pressure sensors are going to enhance physical-digital interaction

Touch is one of the most important and instinctive senses we use to experience the world around us. The essential balance between aesthetics and functionality will benefit from new possibilities unlocked by these sensors

The integration of haptic actuators in products offers several advantages in terms of advanced functionalities, bringing new life to the classical human-object interaction.

Even before Virtual and Augmented Reality came, the need for such useful tools was already under consistent development in some industries such as that video games, entertainment, and some other consumer products. Nevertheless, these systems quickly demonstrated their limits due to their pretty basic mechanical architecture.

Gallery

Open full width

Open full width

Currently, most of the haptic actuators are still based on electro-mechanical motors that provide sufficient and stable performances, even though they eventually result in too rigid, bulky, and cumbersome structures to be used for wearable haptics and or more immersive AR/VR applications. Thus, new materials and structures that can provide more flexibility and more control (literally) are under investigation and offer promising results.

Haptic actuators – examples to explore:

Flexible multifunctional sensors by Sateco

Sateco has been developing silicone-based systems that go beyond the limits of rigid structures of common FSR (force sensor resistors), which usually consist of printed electronic devices, and are basically flat and inelastic.

Thanks to the use of silicone, a material with limitless potential in terms of shape, texture and customization, and to their expertise on sensors in several industries, they produced a capacitive-force sensor composed of two components, both made of electrically conductive silicone, which includes passivation.

The silicone elements are connected together via a simple folding technique, and the whole sensor is then attached up to the controller via other contacts and wiring. Due to the intrinsic elasticity of silicone, the whole sensor can bend and then be applied on curved surfaces, without compromising a fundamental aspect: clarity of the input signal.

The sensor is capable of detecting proximity via the capacitive operating principle and is able to measure compressive forces and convert them into electrical signals. In this way, both proximity and compression can be detected at the same time and can be customized to produce custom interactions.

3D Smart Touch Sensing by TG0

Tg0 has developed a patented capacitive sensing technology can that can be deployed onto any surface in any shape as it is made of a uniform, injection-moldable material able to replace electronic sensors with tactile material, creating 3D controls that are simple, inexpensive, sustainable and intuitive.

The sensor is capable of sensing not only if, but where and how it is touched, as it is also pressure-sensitive. The soft material can provide high-definition analogue pressure signals, and it can be molded to any 3D shape to facilitate any physical interaction. Its composition enables the reduction of significant electronic content and a cost-saving production.

After years of research in the development of real applications, TG0 has recently launched Etee, a controller for video gaming, and has exhibited a Demoset at Automotive Interiors Expo 2022 in Stuttgart in November 2022.

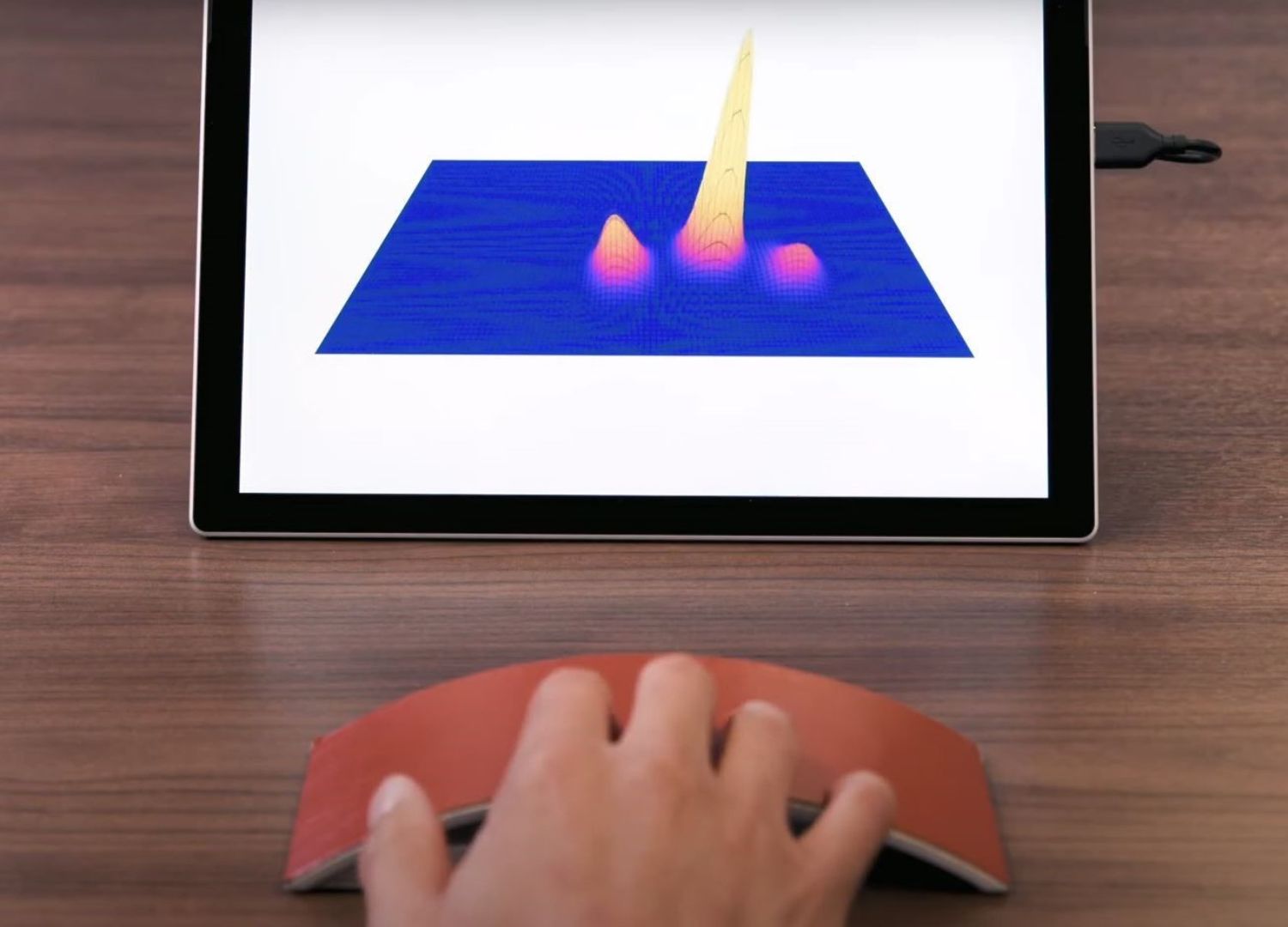

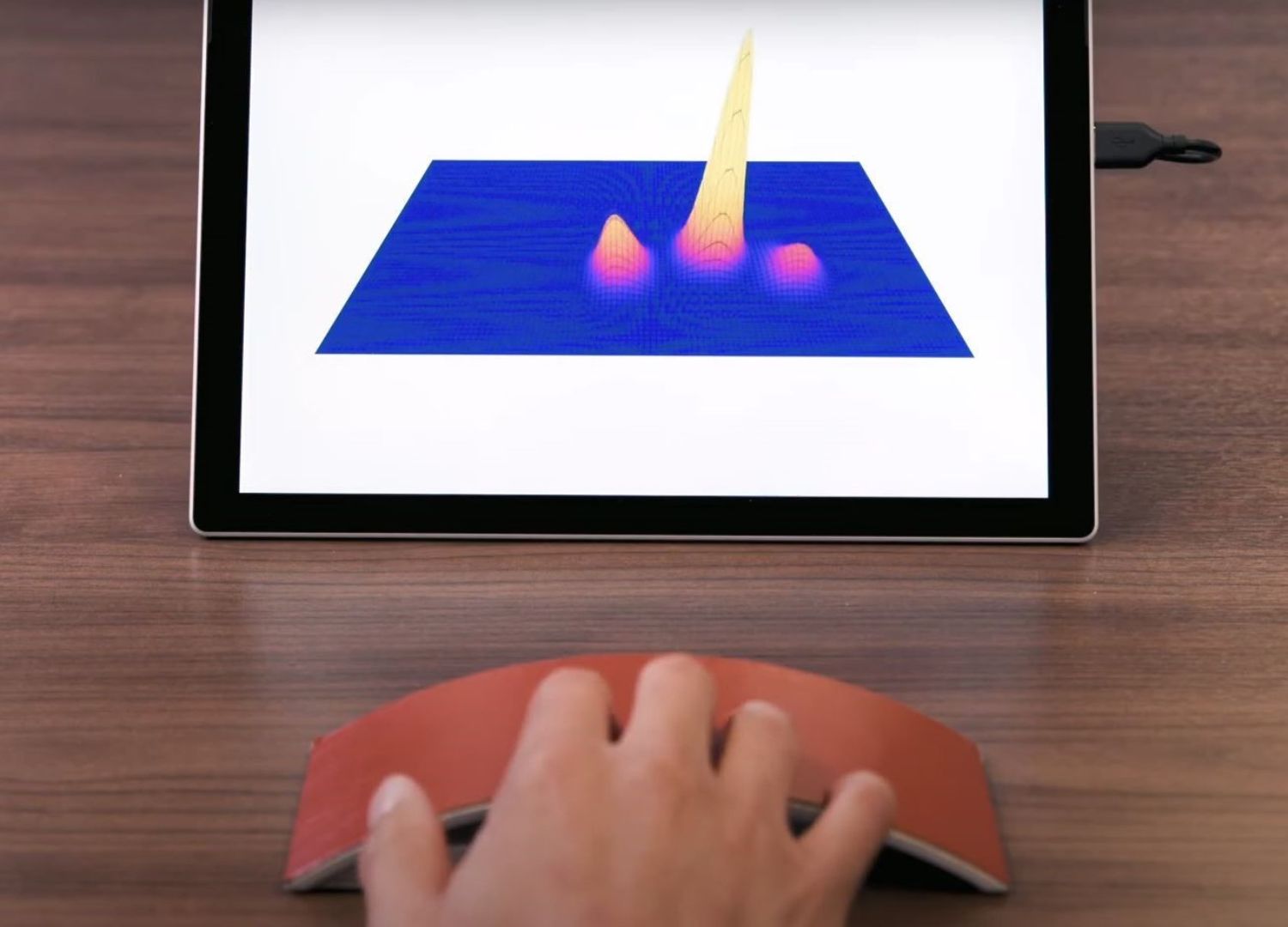

The Pressure Grid by Sensel

Pressure Grid is a technology architecture from Sensel that integrates touch-sensing, force-sensing, and haptics into a single solution. On a basic level, it offers similar performance to most common smartphone touchscreens, but with the huge advantage of full functionality with gloves or even underwater.

Some of the main features of this technology are its capability to recognize virtually any object (not just your fingers); and that the interaction can be carried out in virtually any environment, including water or other mediums.

The sensors can be used in any product as the surface material can be made of plastic, leather or wood and the whole architecture enables a wide range of control modes by the user.

The technology has been out for a while, but it has recently (June 22) received strategic investment from Lenovo, the global technology powerhouse and world’s largest PC manufacturer. This leads to better chances for industrial scalability and real application of Pressure Grid technologies into daily-use devices such as smartphones or laptops.

Haptic actuators: what are the applications?

We’ve seen a series of interesting solutions from different companies facing new challenges in product design in order to achieve advanced functionality and overall a better customer experience. One of the most natural fields for haptic actuators would be that of automotive HMIs, where design and engineering of seamless interiors with best-in-class capacitive touch sensing control is becoming more and more relevant and requested.

As for everyday consumer goods, we can think of the sector of home appliances with multi-function remote controls with advanced and intuitive interfaces, but also that of audio devices and headphones, where integrated, seamless commands would enhance the final user experience and blend naturally with the audio experience.

As for optimal exploitation of the high-quality digital data collected by these sensors, they could be used in smart mats or equipment for fitness and related performance analytics, or even in the biomedical sector as monitoring and assisting devices in the rehabilitation phase.

What could be the future outcomes?

Despite the apparent “non-disruptive” innovation at sight, we report some interesting evolution, both in terms of development and applicability in solutions that have been around for a while, which incorporate pressure sensors and haptic feedback.

The future of digital-physical interaction would be focused on transforming ordinary surfaces into extraordinary tangible experiences, that are constantly gaining more popularity and value if compared to the material object itself.

Smart integration, whether it is embedded in textiles, consumer goods, high-end devices, wearable or in the biomedical sector, will improve the user experience and thus respond to the public rising expectations towards products in terms of novelty and usefulness.