Solving architecture’s waste problem through terrazzo’s traditional craft

Spolia is Solus Ceramics’ newest product, which uses construction waste to create sustainable and beautiful terrazzo tiles within a UK-based circular production system.

One of the world’s most polluting industries is the construction industry, which generates around 61% of total waste in the UK. Despite many efforts, millions of tonnes of potentially valuable materials continue to be discarded. British company Solus Ceramics has developed an innovative solution to this global issue by transforming demolition waste into high-end architectural surfaces. Through their Spolia terrazzo range, they elevate debris into design materials, creating a new model for circular practices.

To understand the significance of Spolia, one must understand the heritage of the terrazzo material itself. Terrazzo originated in Italy in the 15th century, from Venetian workers who were searching for a way to use discarded marble remnants. They discovered a technique to integrate marble chips and glass into a low-cost flooring material, making terrazzo one of the world’s first “green” systems. Just as Venetian workers found beauty in marble scraps, Solus Ceramics has found a way to give that beauty back to construction waste, using tradition to address today’s challenges.

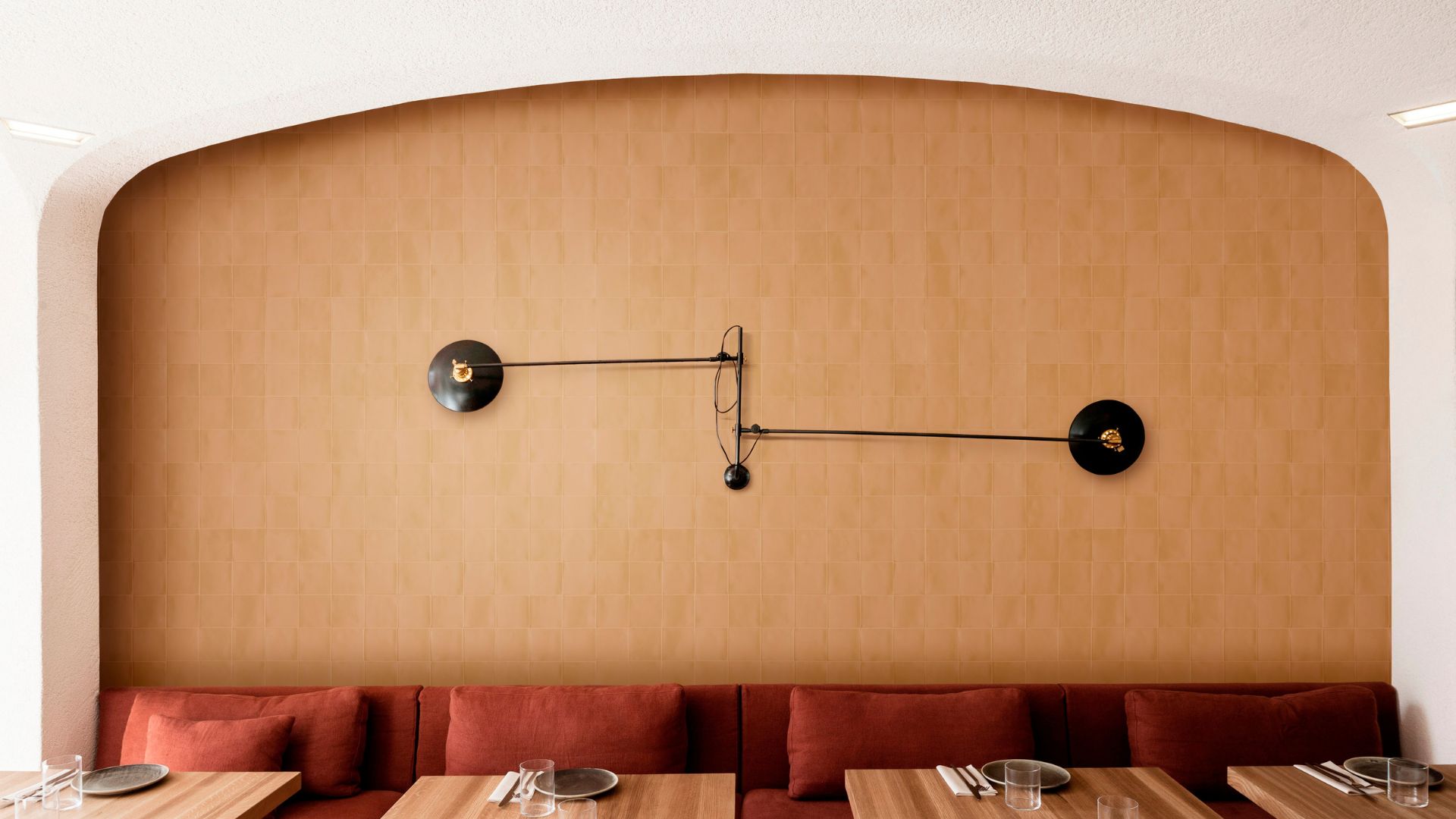

Gallery

Open full width

Open full width

The name of the project itself, Spolia, carries historical significance. In archeology and architecture, spolia is a latin word that refers to the reuse of materials from older structures, a practice common throughout history from Roman times to the medieval period. The result is that you could find decorative pieces from ancient columns being used as brick in a city wall, used both as a physical resource and for an aesthetic difference. By using this term, Solus Ceramics acknowledges the tradition of material reuse and establishes a narrative that speaks about the preservation of architectural memory, beyond just functionality.

While sustainability is central to Spolia’s identity, its technical performance has not been compromised: each tile is unique and meets the rigorous standards of architecture. The manufacturing is conducted by Quiligotti, a family-owned business in the UK that has been producing terrazzo since 1935, using locally sourced materials and aggregates from Europe. Quiligotti’s adaptability is a demonstration that established manufacturers are able to change their processes to accomodate more sustainable practices, without sacrificing quality or efficiency.

Spolia is a symbol of the principles of circular economy thinking applied to the construction industry. Rather than following the traditional linear model of “take, make, dispose”, the Spolia process creates a closed loop where waste from one project becomes the raw material for another. By transforming not only the end life of a material but its overall image and the perception of its worth, the company is helping to shift industry perceptions about what is a valuable material.

More than a sustainable building material, Spolia is a continuation of terrazzo’s original spirit of innovation and resourcefulness. In this project, sustainability and beauty are not competing priorities, but can be mutually reinforcing. When done thoughtfully, sustainable design can create materials that are also more unique, interesting, and meaningful than their traditional alternatives. We hope that the success of this idea can inspire other manufacturers to rethink their approaches, transforming the lifecycles of materials in our built environment. Spolia is a fitting tribute to the ingenuity of those Venetian craftsmen who first saw beauty in marble scraps, centuries ago.