At the forefront of 3D printing – Interview with Lior Elgali of Stratasys

Application Engineer and Product Manager Lior Elgali guides us along Stratasys innovation path in 3D printing technologies

Additive manufacturing company Stratasys has been helping businesses to design better products for three decades.

Design reaches a whole new level of realism with Stratasys, the world’s leading 3D printing company empowering global businesses to produce faster and smarter, using the latest additive manufacturing technologies.

With a background experience of over thirty years, Stratasys drives the change in 3D printing technologies offering a comprehensive choice of printers, together with knowledge, consulting, training, workflow management and end-to-end support.

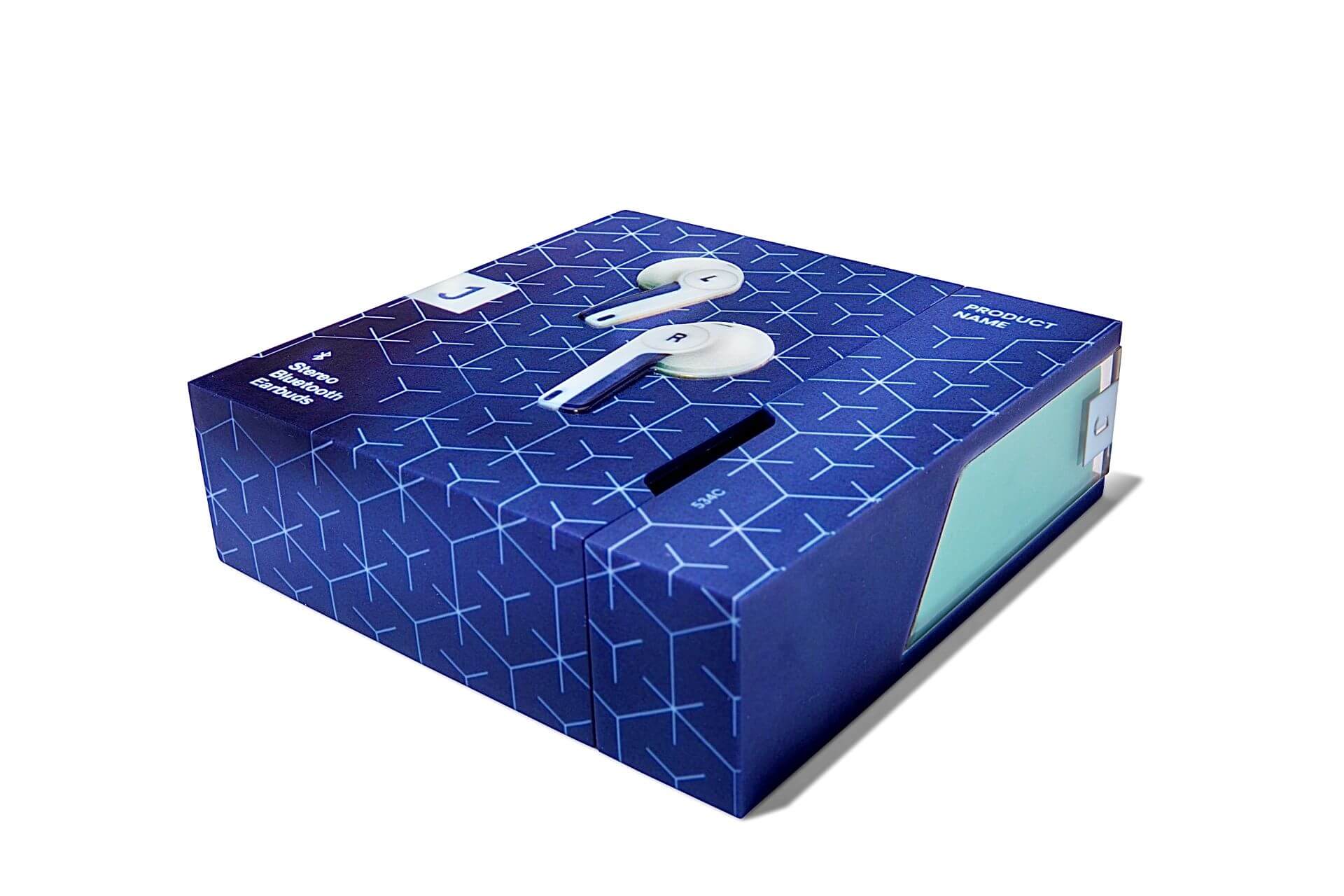

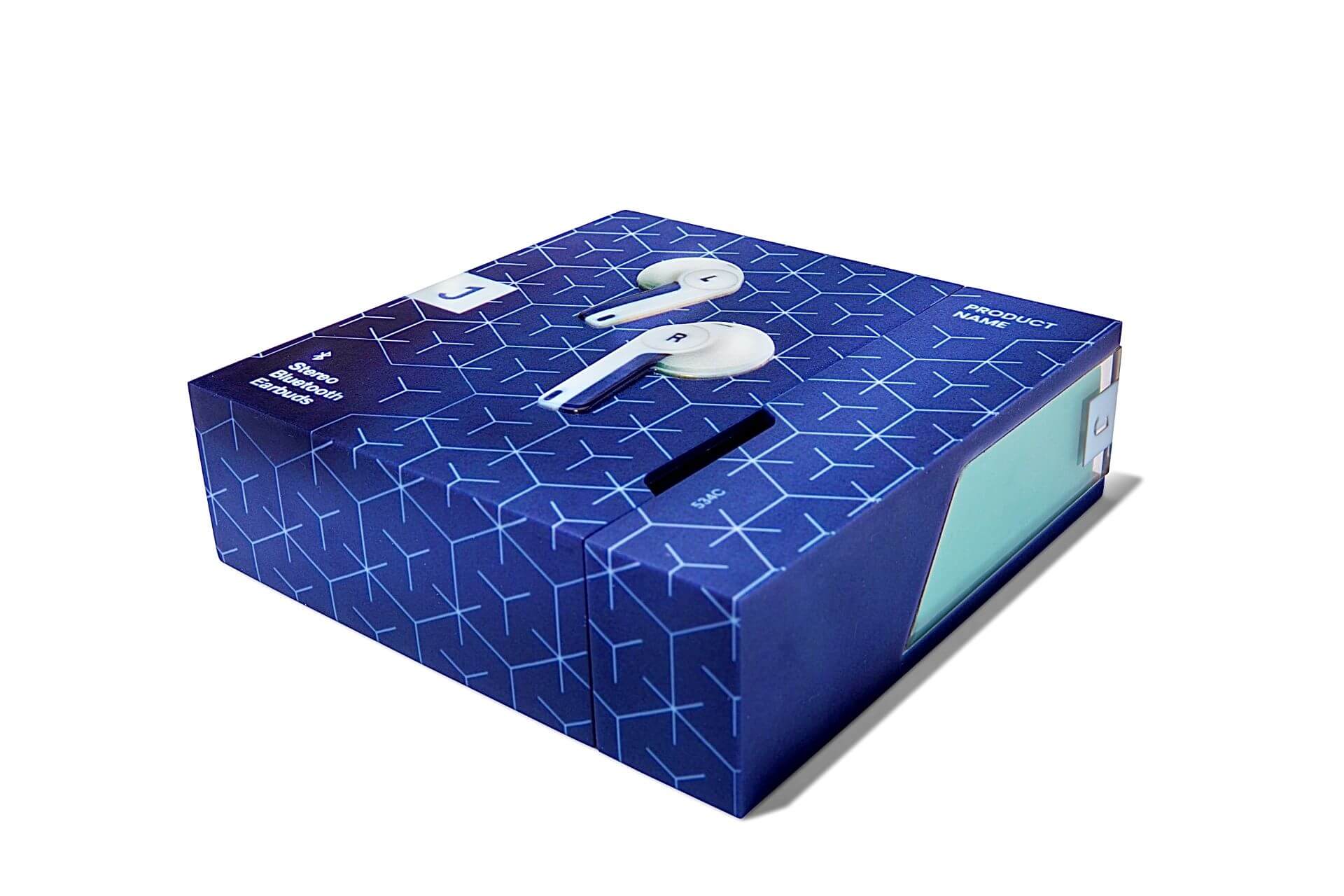

Among the systems provided, PolyJet full-color multi-material allows bringing creative ideas to life, achieving a product’s real impression and considerably shortening the prototyping process.

The Product Manager within Stratasys’ Design Business Unit, Lior Elgali, states “with traditional prototyping, it would usually take days to match one, or a few colors for a prototype: now, we’ve shortened it from days to hours“

Eager to understand further the values and practices of the 3D printing pioneer Stratasys, DesignWanted took the chance to interview Lior Elgali, finding out about his design journey, role inside the company, major innovations, upcoming trends predictions and further steps.

Who is Lior Elgali? How did your journey in design begin?

Lior Elgali: “Somewhere at the age of 11-12 I started playing with 3D Studio Max and Photoshop – that led me to designing and developing websites and applications.

In my time doing that, I found the most exciting part for me was getting the customer’s story, defining the problems and solutions (the bolder the better).

I then went on to get a B.Design, and after about a year of freelancing and developing my own product I joined Stratasys, specifically focusing on its PolyJet full-color multi-material 3D printing technology.”

As Global Design Expert, what is your role at Stratasys and how does it contribute to the company vision?

Lior Elgali: “I am a Product Manager within Stratasys’ Design Business Unit. My work starts with identifying the problems faced by designers, researchers, engineers, and others, in various industries and markets.

To do that effectively, I work closely with our customers – some of the world’s leading and most innovative companies in their fields.

I listen to their problems and learn about their workflows and needs.

As a product designer myself, I can identify with many of their needs – and knowing the technology inside-out, I can define optimal scenarios where we can have an impact.

Then, working with the product team and our R&D, we come up with the best ways to improve the workflow, appearance, and other aspects of our solutions.

Eventually, once the product is developed, I try to find the best ways to share it with our customers and partners – through sample parts, webinars, blog posts, tutorials and more.”

Stratasys brings ideas to life through 3D printing, ensuring a new level of realism through a full-colour range and multi-material printing. How are Stratasys solutions different from the ones of other 3D printing companies and who are they catered to?

Lior Elgali: “We believe the product design / industrial design market is facing some great challenges that we are capable of providing solutions for. Instead of chasing features, we try to look at the design process through the customer’s eyes – and budget.

We work on streamlining the prototyping workflow, and bring CMF (Color, Material, Finish) prototypes faster and easier.

We identified that by eliminating needless side-workflows, and bringing the whole prototyping solution – specifically the CMF prototypes – closer to the designer, we can help speed up design iterations by up to 200%, reduce the designers’ modelling time by up to 50%, reduce the CMF model cost, and reduce the time-to-model to just one day. All of this translates to faster time-to-market, and more confidence in the design throughout the process.”

3d printing and additive technologies can be used to produce sustainable products: The New Raw turns plastic waste into furniture through digital fabrication.

Rendering software KeyShot 10 recently partnered with Stratasys: how does this affect the work of product designer?

Lior Elgali: “This is a game-changer for a product designers’ color prototyping workflows.

A huge portion of product designers are using Keyshot for most of their CMF and rendering work (myself included – since my first year in design school).

This means the model in Keyshot already contains all of the appearance data – geometry, colors, materials, graphics, finishes, transparencies – and it usually ends up either a great render, or as a pdf guide (CMF Doc) for producing a High-Fidelity prototype with many different tools and practices.

This prototyping process usually requires outsourcing, with long lead-times, high costs, and very few prototypes.”

Lior Elgali: “Together with KeyShot we broke through this barrier – making it possible for any product designer to now export their design as a 3MF file directly from Keyshot containing their geometry, color, material and finishes.

Our printing software, GrabCAD Print, can then load these 3MF files and print them with full colors, transparency, graphics and more – on our PolyJet-based J Series 3D printers.

With J55 being an office-friendly full-color 3D Printer, this means the designer can now go from a keyshot file to holding a physical full-color part in their hand in a single day.”

To what extent are Stratasys 3D printing solutions contributing to environmental and social sustainability? Can you tell us more about Stratasys Recycling + Returns Program?

Rosa Coblens, VP Global Sustainability: “Stratasys has been very active in Corporate Social Responsibility for many years.

Our vision clearly states our commitment to leveraging the value of 3D printing to the benefit of our local communities through meaningful partnerships and personal employee contributions via our global volunteer network.

We partner with academic institutions to advance STEM programs through “learning by making”, securing accessible 3D printers and connecting experts (our employees) to teachers and students around the world.

We also serve the medical community providing solutions for medical devices that no other technology can provide in such a personalized and immediate way – prosthetics and accessibility tools.

We were especially prominent in this field during the 2020 COVID pandemic, where we recruited our global network to create personal protective equipment overnight – no shipping of materials, products or printers (so no added carbon footprint!). “

Rosa Coblens, VP Global Sustainability: “Beyond our vast social undertakings, we are proud to promote sustainability by impacting supply chains.

By its very nature, additive manufacturing saves time, money and material with its advanced prototyping models printed on-demand and our solutions for industries like aerospace and automotive; here we make storage of inventory and shipment of parts nearly obsolete. You need a part, you have the file, print it.

We also have popular recycling and reuse programs across geographies (America, Europe and Asia).

Partners and customers return canisters that are then reused and refilled. We are expanding this program to additional areas and machines.

In 2020, Stratasys’s new CEO established a function fully dedicated to Sustainability. It is a part of our company strategy and DNA.”

According to you, what are the main upcoming trends related to product design in connection with 3D printing?

Lior Elgali: “I think a few paradigm shifts will happen, based on my personal experience with the field:

More designers will use colors earlier in the design process: as things get easier and more cost effective (such as what’s mentioned above – Keyshot CMF to 3D print on the J55), it starts making sense to include this crucial element of product design into the earlier decision-making.

Color, Material, Finish, and Graphics affect product design in such a profound way, that we will be laughing about the “old days” when designers only introduced them on high-fidelity and marketing prototypes.

Using AR, combined with the printed model: some changes need to occur simultaneously for the design to flow.

Combining a 3D printed, high-resolution object with projected interactive visuals is a logical future step for advanced prototyping.”

More connectivity: today many design tools have their own file transfer formats, their own language and standards – but designers require switching between tools, especially in 3D printing.

With the advancements in 3MF and other connectivity tools, designers would have less to worry about the workflow and what works where and could focus more on design.

Customized, innovative designs: as was always the dream of 3D printing, but has not really been realized until now.

CMF 3D printing allows producing ideas that were too hard or costly to manufacture or prototype – and therefore left on the drawing board in the past.

With the new advanced capabilities and streamlined workflows for full color, material, finish, and graphics, including transparency, saturated colors and more, designers will start experimenting with ever-bold ideas.”

What can we expect from Stratasys in the near future?

Lior Elgali: “We aim to keep simplifying the workflow and making it easier and more accessible to achieve great results on our 3D Printers.

We will continue to work closely with customers to better understand their needs and find ways where we can push the limits of our industry, and be the first choice for CMF, High-Fidelity prototyping.”

Did you know that 3d printing can be applied to the food sector? Find out more, Lunch is printed: Upprinting Food transforms scraps into snacks.