A collection crafted from the new malt wood that plays with perception

Franck Grossel, founder of Instead Mobilier, discusses the brand’s journey since 2020, highlighting key milestones and recent innovations, from bringing production in-house to the development of the new Balt® solution.

Although the combination of beer and furniture might seem unusual, as early as 2020 a pioneering project demonstrated how these two worlds can complement each other: on one side there’s a by-product that accounts for 30% of the brewing output, spent grain; on the other, the search for new material solutions derived from waste that can be recycled at the end of their life.

At the heart of this initiative is Franck Grossel and the brand he founded, Instead Mobilier, which has been exploring these possibilities from the very beginning.

Gallery

Open full width

Open full width

Five years after our first interview, we return to speak with the team to discover the latest progress and how the project has evolved: from the opening of the new “furniture brewery” in Nantes in 2024, to the launch of the new collection and the new tones and finishes of the material.

At Maison & Objet, you unveiled the new Citra Collection. Can you tell us more about this line – its concept, the products it includes, and how it represents the evolution of Instead Mobilier’s identity?

Franck Grossel:

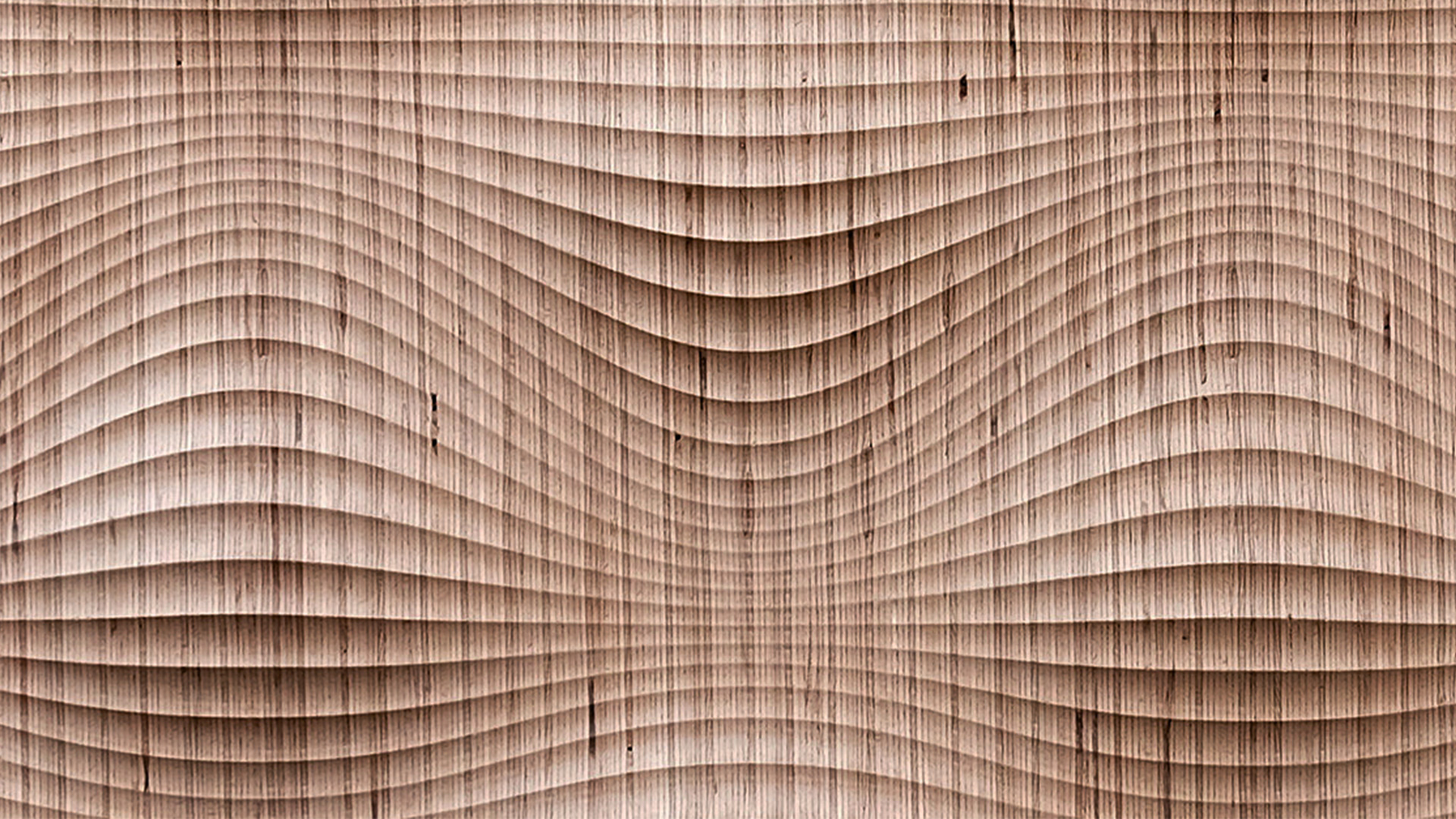

The Citra Collection, introduced through our side table, is the first product made entirely from Balt®, the “malt wood” material we developed at Instead. It represents both a technical milestone and a creative playground to explore new textures and forms.

With its stone-like texture, Citra plays with perception and invites people to question the nature and origin of the material itself. At first glance, it may look mineral, but as you get closer, its organic, plant-based essence becomes visible. And unlike beer, which inspired it, our material is warm to the touch. Citra is therefore not just a collection, it’s a conversation between material, design, and story.

From spent grain to the new Balt® – it took three years of research and the addition of a new ingredient, recycled food packaging. Can you explain how this development process unfolded and how the formula has evolved?

Franck Grossel:

At first, we worked entirely through industrial subcontractors, relying on heavily equipped partners to produce our material. But over time, we faced growing challenges as delays, limited flexibility, and little room for exploration. So we made a bold move: to internalize the entire process and become furniture makers ourselves, inside what we now call our “furniture brewery.” Since then, we’ve grown from one to twelve products, from three to eight team members, and from a single finish to six.

Most importantly, this shift allowed us to transform the weaknesses of our first material version into true competitive advantages improving texture, durability, and design potential. Balt® today is the result of that transformation: a material born from constraint, refined through experimentation, and matured like a good craft beer.

What inspired the new Balt® tones and finishes?

Franck Grossel:

To stay connected to the world of beer, we developed Balt® in the same spirit with shades like Blonde, Amber, Brown, White, and Stout. These became our standard tones. More recently, we’ve even created marbled variations, inspired by beer blends, a playful nod to brewing craftsmanship.

What’s fascinating is that our Brown tone, the natural color of the material, actually comes from the mix of spent grain and recycled single-use food packaging, naturally darkened by the caramelization of residual sugars from brewing. To achieve the Blonde, we use wheat by-products to soften that caramel effect. For Stout, we incorporate coffee grounds, just like in the brewing process for darker beers. And for White and Amber, we use bio-based pigments that preserve the material’s organic texture. Each tone tells a story rooted in the brewing process, yet reinvented through design.

Balt® is also available to professionals who wish to design more environmentally responsible spaces and products. Could you describe its main characteristics, material performance, and available dimensions and finishes?

Franck Grossel:

Unlike traditional panel manufacturers, we don’t produce large sheets that we then machine. Balt® is prepared as a paste, which we compress and cool directly inside molds shaped to the final product. This process gives us high production efficiency with very little post-production: no heavy CNC machining or complex assembly steps.

At the moment, our size limit is defined by our hydraulic press, which allows us to produce pieces up to 800 × 800 mm. For larger applications, we can create thin Balt® sheets and use them as veneers to cover bigger panels, opening creative possibilities such as marquetry or surface inlays. Balt® is stain-resistant, scratch-resistant, and fully waterproof, making it ideal for indoor use. We’re currently developing an outdoor version, which brings even higher technical challenges!

How do you manage the end-of-life of Balt® furniture?

Franck Grossel:

Today, one of the major issues with bio-based single-use food packaging is that no real recycling stream exists in France for these materials. Rather than letting them end up in incineration, we decided to give them a second life, transforming them into durable, resistant furniture that helps capture and store CO₂ over time. We chose to work with a matrix that isn’t recyclable yet, unlike conventional plastics such as PP, precisely because we wanted to extend its life cycle through design.

As for recycling, we can reprocess Balt® ourselves in a closed loop: we collect, grind, and reintroduce the material directly into our production process. That way, every piece can be reborn, again and again.

In May 2024, Instead opened its first “furniture brewery” in Nantes. With 200m² of workshops and 80m² of offices, how has your production capacity and workflow evolved within this new space?

Franck Grossel:

The opening of our furniture brewery in Nantes has completely transformed our production capacity. With 200m² of workshop space dedicated to material transformation and molding, we now manage the entire process, from the creation of Balt® to the finished furniture.

Our system is highly efficient: we only run our machines twice a week for three hours each session, yet we produce an average of 20 pieces per hour, around 100 finished products per week, with only three furniture brewers. This efficiency lets us stay faithful to our philosophy: local, low-energy, and high-quality production, while leaving room for prototyping, finishing, and R&D during the rest of the week.

And this is only the beginning. By early 2026, we’ll be expanding with an extra 300 m² warehouse, allowing us to scale our production, welcome new talents, and continue developing the next generation of circular materials and furniture.

This new site also allows you to experiment with new eco-materials and low-carbon processes. What types of materials or sustainable innovations are you currently researching and developing?

Franck Grossel:

Right now, we’re working to make our material fire-resistant, which will allow us to access new markets and applications. We’re also developing an outdoor version of Balt®, to create a full outdoor furniture line, an area where very few truly sustainable solutions exist today.

At the same time, we’re exploring new materials and new stories, experimenting with bio-based blends, local by-products, and alternative recipes that push the boundaries of circular design even further.

For us, each new material is an opportunity to question the way we make things, and to imagine how design can help turn waste into something meaningful.