KOODESIGN on the strategic role of Design for Manufacturing (DfM)

Specialized in technology-driven products, the Hong Kong-based studio combines in-depth research with a Go-To-Market strategy to transform ideas into scalable solutions ready for efficient production.

Founded by Larry Koo and Natalie Chan in Hong Kong, KOODESIGN is an award-winning product design and brand-communication consultancy. Thanks to its combination of industrial design expertise and technological know-how, the studio creates functional, effective solutions for international clients – translating ideas into simple, intuitive user experiences.

A key element of their process is Design for Manufacturing (DfM). Throughout the design phase, the studio places strong emphasis on researching manufacturing methods, materials, and industrial processes that can bring a client’s idea to large-scale production.

Gallery

Open full width

Open full width

We spoke with Larry Koo, Design Lead of the studio, to explore this aspect further and to understand how thoughtful design can truly bring ideas to life.

Your studio’s areas of expertise are closely linked to technology: in addition to sports products, you develop projects in consumer electronics, IoT-enabled accessories, and audio speakers. How is the design of these products evolving with the rise of Artificial Intelligence? Is AI already integrated into your processes?

Larry Koo:

“Design with technology for humanity” is at the core of our philosophy. Hong Kong is just an hour from Shenzhen, which is like the Silicon Valley of the East, so we are ideally placed to collaborate with global innovators like Philips Design, Lenovo, and TCL, all of whom have established design centers in the region.

AI has become integral to our process, enhancing everything from research to concept development. For instance, when we were designing a smart helmet with telecom and traffic warning functions, we input initial hand sketches into an AI platform. This allowed us to rapidly generate a wide array of fully rendered concepts. Our team’s expertise guides how we prompt and refine AI outputs, ensuring high-quality, actionable design references.

In your approach, you reference A. Einstein’s quote: “Out of Complexity, find Simplicity!”. How do you manage to transform complex products into simple, intuitive user experiences? Could you share a concrete example of a project?

Larry Koo:

A good example that embodies our intelligent reduction approach was when we designed an award-winning electrical safety device for Eaton Ltd., a global leader in power management. The project involved redesigning an ATS (Automatic Transfer Switch) by applying the principle: “find simplicity.” We transformed a cluttered interface, condensing three distinct control buttons into one intuitive slider switch, making the system more streamlined, legible and user-friendly.

Beyond the interface, our integrated design and mechanical engineering approach led us to refine the physical form. We identified under-utilized space within the unit’s existing housing, allowing us to integrate a previously exposed external lever into a secure, dedicated internal compartment. This consolidation elegantly resolved visual clutter without compromising utility.

This aligns with our principle of reducing visual clutter via feature integration. By thoughtfully consolidating the components, we maintained full functionality while achieving a cleaner, more refined aesthetic. And the ATS was later recognized with an iF Design Award in 2023.

Every design project begins with an in-depth research phase that includes trend analysis, competitive benchmarking, and the definition of key insights. How does this research influence creativity and guide the project’s flow?

Larry Koo:

We think of design as discovery, and as a scientific approach to innovation. Before any concept takes shape, we enter a process of deep research and analysis. This phase is foundational. We map product use cases, benchmark competitors, assess brand positioning, cultivate user empathy, and define essential features to build a strong business proposition. By uncovering core pain points, we analyze the design problem more holistically, often thinking beyond the initial brief. Crucially, we never jump from discovery to design. Instead, the key insights from our research become the compass for innovation, ensuring we solve the right problems in the right direction.

A good case study reference would be an E-Mobility scooter that we designed for a client with a strong solar energy background, but a newcomer to e-scooters. From starting at the highest level, we first understood their sustainability ethos and how e-mobility fit their portfolio. We analyzed the consumer market, built user personas, and identified the essential e-scooter archetype.

Understanding the target audience and technical drivers from the outset allowed us to innovate with precision, crafting a solution that properly aligned with the client’s vision and market reality. This is a fundamental part of our process – knowing why and who you are designing for.

Working with clients around the world, you have extensive experience with a Design for Manufacturing approach. What does it mean to design according to this principle, and what are the main challenges you encounter with clients?

Larry Koo:

Our promise is simple: “bring the idea to life!”. This drives every project through a strategic Go-To-Market methodology that blends innovation with practicality to solve design challenges.

A cornerstone of our process is Design for Manufacturing (DfM), which bridges the gap between stakeholders and production suppliers to ensuring that every design meets strict business and production criteria, while also staying human-centric. Our team often works on-site with manufacturers to ensure a seamless ramp-up to mass production.

Knowledge fuels our growth, and the insights gained from one product archetype help us drive innovation in the next. Our design mindset thinks beyond products – our goal is always to build scalable, manufacturable success.

The studio is aware of the role design plays in creating a smarter and more sustainable future, with particular attention to responsible production, sustainable materials, and intelligent design solutions that generate a positive impact. Could you give us an example of a project guided by a sustainable approach?

Larry Koo:

Sustainability is not treated as a separate layer in our work, it is embedded into how we define and solve design problems from the outset. For us, design is about creating products that are purposeful, durable, and relevant over time – reducing waste through responsible design.

One example is the Onanoff Fokus, a distraction-free headphone set designed for children. The project was driven by a clear intention to supports focused learning and avoids unnecessary distractions. This reduction in complexity leads to a longer product lifespan, lower digital dependency, and a more responsible relationship between the user and the device. Material choices, robust construction, and intuitive interaction were all guided by the goal of sustainability and longevity rather than rapid replacement.

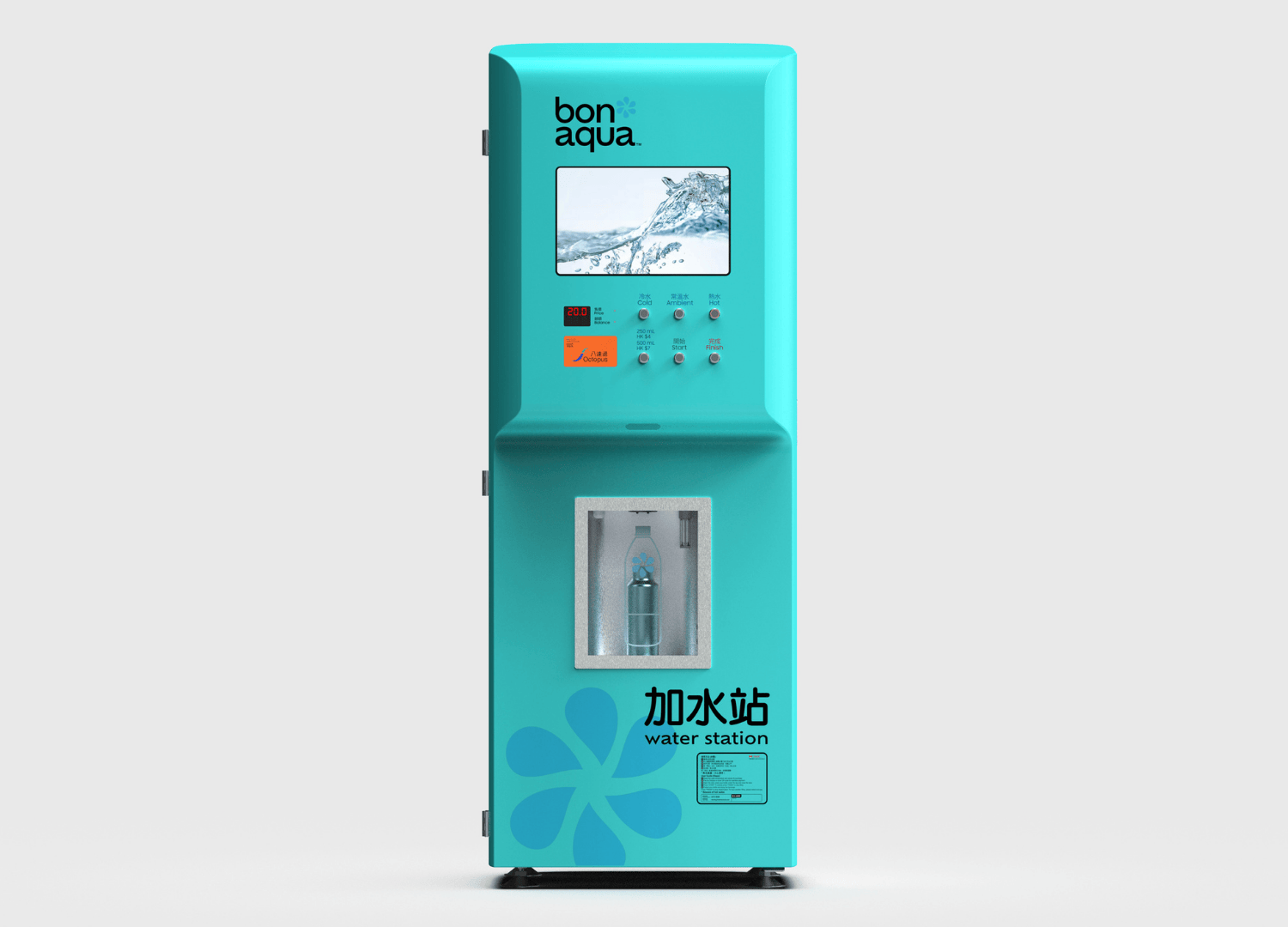

A different expression of sustainability can be seen in our Bonaqua Water Refill Station concept developed for Coca-Cola. The project addressed the need to reduce single-use plastic by encouraging refill behaviour in public and semi-public spaces. Designed in two scalable formats for indoor and outdoor environments, the station combined touchless interaction, clear user guidance, and a compact footprint to ensure hygienic, efficient use. Every decision balances functionality, adaptability, and visual simplicity, demonstrating how thoughtful design can support more sustainable everyday habits at scale.

You emphasize that “design is communication.” How do you shape a product’s story through form, materials, and visual language?

Larry Koo:

We believe design is a form of communication where form, materials, and visual language work together to express purpose, function, and trust. Good design signals how a product should be understood and used. Across all categories, our goal is the same: let the product tell its story at first glance.

On technical products like the Eaton Automatic Transfer Switch, clarity and precision in form support usability and operational confidence. The language of “modern utility” guided the proportions, modularity, and details so that even a complex industrial device feels purposeful and intuitive, reinforcing both brand character and user trust.

In consumer-oriented products, expressive form and material choices help convey personality and performance. The Arena Spider goggles uses tailored shapes and recycled plastics that signal both comfort and playful energy while aligning with sustainability values. And with the Michelin 5818 tire compressor, a streamlined, robust aesthetic communicates durability and mobility, while thoughtful alignment of UI elements makes interaction clear and confident at a glance.